Such a scene often occurs during control valve selection meetings:

The procurement manager asked: "Why not use this ball valve? Its Cv value is twice that of the clumsy globe valve, it costs only half as much, and it's far more compact and lightweight."The instrumentation engineer frowned, responding: "This loop demands high-precision control ,and a ball valve won't cut it."This is the eternal trade-off between economy and control performance.Rotary valves (e.g., ball valves, butterfly valves) indeed hold an overwhelming advantage in flow capacity and cost. Yet as the final control element, VATTEN VALVE cannot focus merely on their flow rate; what matters more is the precision of their control.

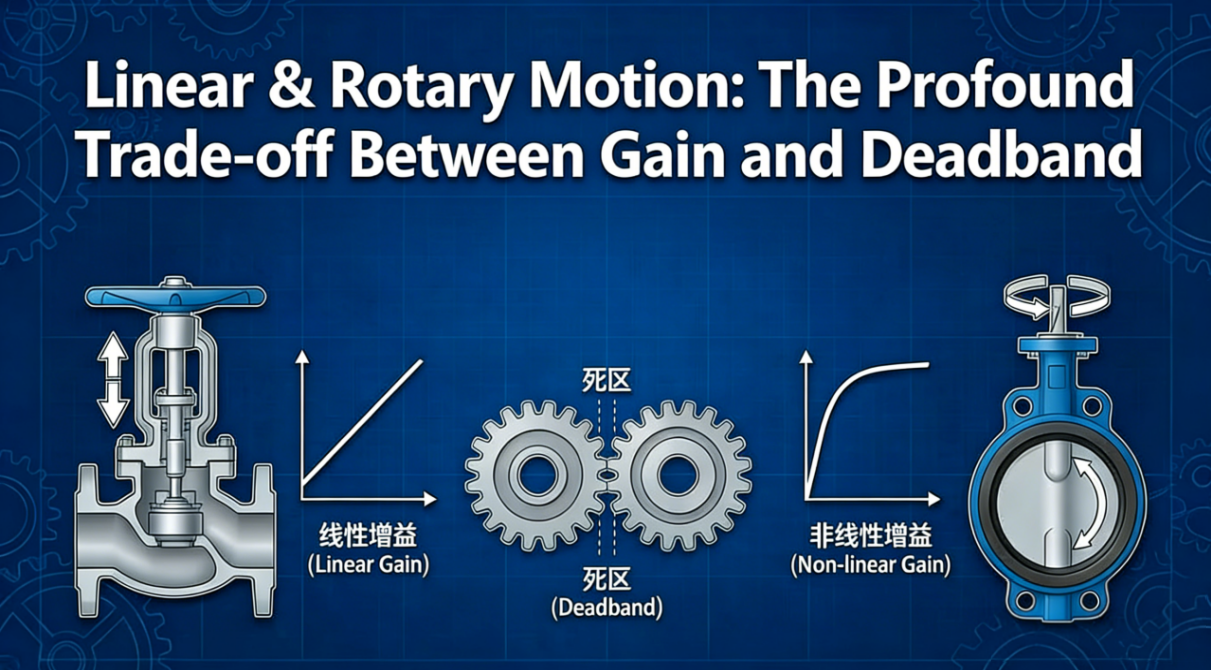

Today, VATTEN VALVE will delve into the realm of control theory and compare the fundamental differences between linear and rotary valves through two hardcore metrics: Gain and Deadband.

01.Two Major Categories by Structural Design

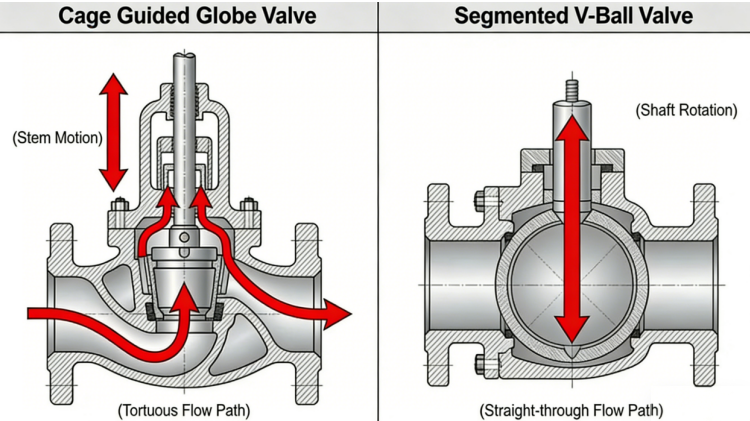

1.Linear Motion Valves

The valve stem drives the valve core to move linearly up and down.

Representative: Globe Valve, including single-seated, double-seated and cage-guided types.

Features: Extremely robust structure, tortuous flow path (high energy dissipation), and easy realization of precise flow characteristics.

2.Rotary Motion Valves

The valve shaft drives the valve plug to rotate (typically by 90°).

Representatives: Ball Valve (including V-port ball valves), Butterfly Valve, and Camflex Valve.

Features: Simple and straight flow path, ultra-high flow capacity, compact structure, and easier achievement of environmental protection requirements for packing seals.

Key Illustration: Structural Comparison

02 Profound Trade-off 1: Installed Gain

By taking the derivative (slope) of the flow characteristic curve, we obtain a more critical metric: Valve Gain.Put simply, gain is the sensitivity of a valve.

Ideal condition: We expect the valve gain to remain constant throughout the entire stroke. This means a 1% command signal from the controller will always result in a 1% flow rate change.

Real-world condition: The gain varies with the valve opening.

The weakness of Rotary Valves: Excessively High Gain and Nonlinearity

Rotary valves (especially butterfly valves and standard ball valves) typically feature an extremely high inherent gain, particularly at small openings.

The "Pop-open" Effect: When a ball or butterfly valve is just cracked open, the flow rate surges instantaneously due to the unobstructed flow path. This means the valve is overly sensitive during low-flow regulation,a slight signal input will cause a sudden spike in flow, which can easily trigger system oscillation.

A Sharp Drop in Gain: The gain of a rotary valve plummets and becomes extremely sluggish once the opening exceeds 60%-70%.

By contrast, linear globe valves (with a properly designed trim) can more easily achieve a relatively stable and moderate installed gain across the entire stroke range ,a huge boon for PID parameter tuning.

03 Profound Trade-off 2: Mechanical Deadband and Stiction

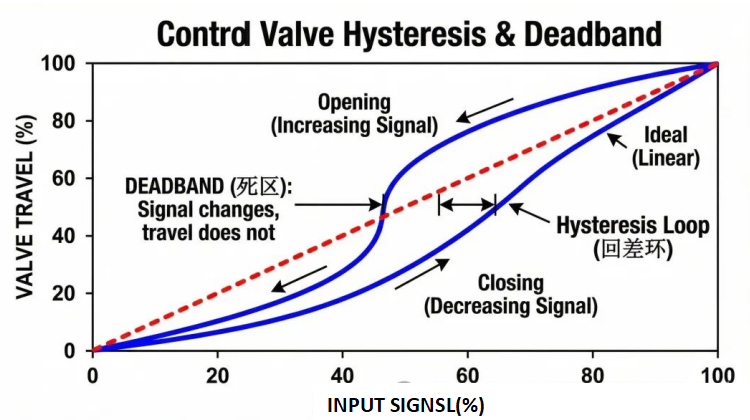

If gain is a software-level issue, then deadband and stiction are hardware-level chronic maladies,they directly determine the precision of control.

Deadband: Null Actuation

When you reverse the direction of the input signal (e.g., switching from opening to closing), the valve must travel a section of null stroke before the valve plug actually starts to move in the opposite direction. This section of null stroke is what we call the deadband.

Challenges for Rotary Valves: To convert the thrust of the positioner’s linear cylinder into rotary motion, rotary valves typically require complex linkage mechanisms or rack-and-pinion assemblies. The mechanical clearance in every connecting pin and spherical plain bearing accumulates to form a significant deadband.

Advantages of Linear Valves: The pneumatic diaphragm actuator drives the valve stem up and down directly, featuring fewer connection links and an inherently smaller mechanical deadband.

Stiction: Crippling Static Friction

Stiction is a phenomenon caused by static friction being significantly greater than kinetic friction. A valve will seize in a fixed position until the air pressure builds up sufficiently to overcome the static friction, at which point the valve slips abruptly to a new position. This causes the controlled variable to exhibit the well-known sawtooth wave oscillation.

Challenges for Rotary Valves: For tight shut-off, the valve seat of a rotary valve typically exerts immense lateral pressure on the ball or valve disc, leading to excessively high friction. Additionally, to meet low-leakage environmental requirements, the packing around the rotating shaft is often highly compressed.

Advantages of Linear Valves: The valve plug and seat of a globe valve are primarily in vertical contact, resulting in low lateral friction during the regulation process.

04 Selection Guide: There is no best, only the most suitable.

VATTEN VALVE will guide you through the selection

When to Choose Rotary Valves:

- High flow rate & low pressure drop: Requiring a large Cv value with a low system pressure.

- Fouling media & slurries: The straight-through flow path of ball and butterfly valves resists clogging, and their rotary motion provides shearing and self-cleaning capabilities.

- Tight shut-off requirements: Soft-seated ball valves facilitate zero leakage more easily.

- Space & Budget Constraints: A compact, cost-effective solution is required.

When to Stick with Linear Valves:

- High-precision control: Critical loops with stringent requirements for deadband and lag (e.g., < 0.5%), such as temperature and composition control.

- High pressure drop & severe service conditions: Multi-stage pressure reducing trim is required to resist cavitation, flashing and high noise (see Ref. No.001). This is the unrivaled domain of globe valves.

- Low-flow regulation: Requiring a micro Cv value and a high turndown ratio.

English

English Deutsch

Deutsch bahasa Indonesia

bahasa Indonesia