Emergency Stop Push Button: Introduction

In every industrial plant, safety is important and is mandatory. Machines rotate at high speeds, pumps generate pressure, conveyors move heavy materials, and automated systems operate continuously. In such environments, even a small mistake can cause serious injury or equipment damage.

This is why every machine is equipped with an emergency stop button. When something unexpected happens, the operator must be able to stop the machine instantly and safely.

One common question asked by students and technicians is: Why is a Normally Closed (NC) contact always used for an emergency stop push button instead of a Normally Open (NO) contact?

The answer lies in safety logic, fail-safe design, and fault detection.

Let us understand this step by step.

Understanding NC and NO Contacts

A push button can have two basic contact types: Normally Closed and Normally Open.

In a Normally Closed (NC) contact, the circuit remains closed when the button is not pressed. Current flows normally. When the button is pressed, the contact opens and breaks the circuit.

In a Normally Open (NO) contact, the circuit remains open when the button is not pressed. Current flows only when the button is pressed.

This simple difference plays a major role in safety behavior.

To visualize this:

- NC contact allows current during healthy operation.

- Pressing the button interrupts the current.

- NO contact blocks current during normal state.

- Pressing the button allows current to flow.

For an emergency stop, interruption of current is what brings safety.

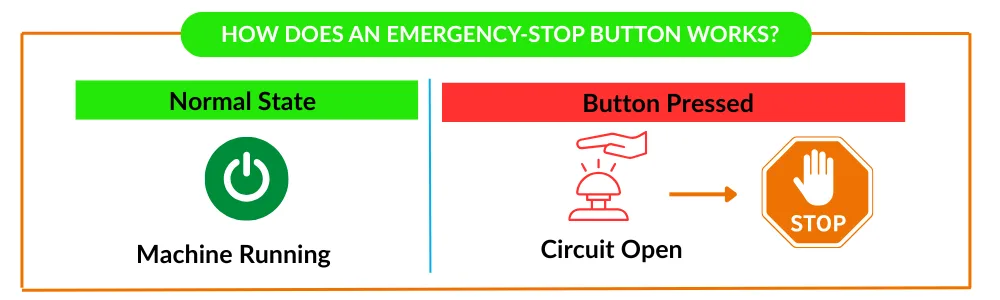

How an Emergency Stop Circuit Works

Let us imagine a motor running on a production line.

During normal operation, the emergency stop NC contact remains closed, allowing control power to reach the contactor coil. The motor keeps running.

When the emergency stop button is pressed:

- The NC contact opens immediately.

- The control circuit breaks.

- The contactor de-energizes.

- Power to the motor is removed.

- The machine stops instantly.

This direct interruption ensures fast response and reliable shutdown. The logic is simple and does not depend on software or programming.

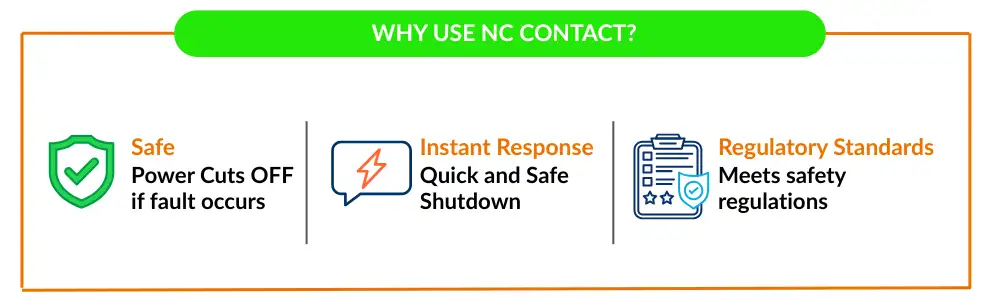

Fail-Safe Behavior – The Most Important Safety Principle

Fail-safe design means that whenever something fails, the system automatically moves to a safe condition instead of continuing operation.

Using NC contacts in an emergency stop circuit supports fail-safe behavior naturally.

Consider these real-world scenarios:

- A cable breaks due to vibration or aging.

- A terminal loosens inside the control panel.

- A push button contact fails mechanically.

- A connector gets damaged due to moisture or dust.

In all these cases, the NC circuit opens — exactly the same as pressing the emergency stop button. The machine stops automatically.

This ensures:

- Faults are not hidden.

- Unsafe operation is prevented.

- Maintenance can identify problems quickly.

- Personnel safety is protected.

If NO contacts were used, many of these failures would remain unnoticed until an actual emergency occurs.

Instant Shutdown During Emergency Situations

In dangerous situations, reaction time is critical. The emergency stop must interrupt power without delay.

NC logic provides this advantage:

- The circuit is already energized in normal condition.

- Opening the contact instantly removes power.

- There is no dependency on signal generation or contact closing.

- Mechanical interruption is faster and more reliable.

This ensures immediate stopping even if control logic or PLC software fails.

Easy Fault Monitoring and Diagnostics

Another practical advantage of NC emergency stop wiring is easy monitoring.

Modern control panels often connect emergency stop loops to PLC inputs or safety relays. If the circuit opens unexpectedly, the system detects it immediately.

This allows:

- Alarm generation for wiring faults.

- Preventive maintenance actions.

- Faster troubleshooting.

- Reduced downtime and improved reliability.

A healthy safety system must continuously verify its own integrity, NC contacts make this possible.

Why Safety Standards Prefer NC Contacts

Industrial safety standards emphasize:

- Fail-safe behavior.

- Fault detection capability.

- Predictable shutdown behavior.

- Hardware-based safety whenever possible.

NC contacts naturally satisfy all these requirements. That is why emergency stop devices, safety door switches, and interlocks almost always use NC logic.

This consistency helps engineers design uniform safety architectures across plants.

Why Normally Open Contacts Are Unsafe for Emergency Stop

Using NO contacts for emergency stop creates hidden risks.

Let us understand why:

- If a wire breaks, the circuit remains open which appears normal to the system.

- The fault remains unnoticed.

- During an emergency, pressing the button may not stop the machine.

- Operators may assume safety while the machine continues running.

This defeats the purpose of having an emergency stop in the first place.

NO contacts are suitable for command actions such as start, reset, or acknowledgment not for safety interruption.

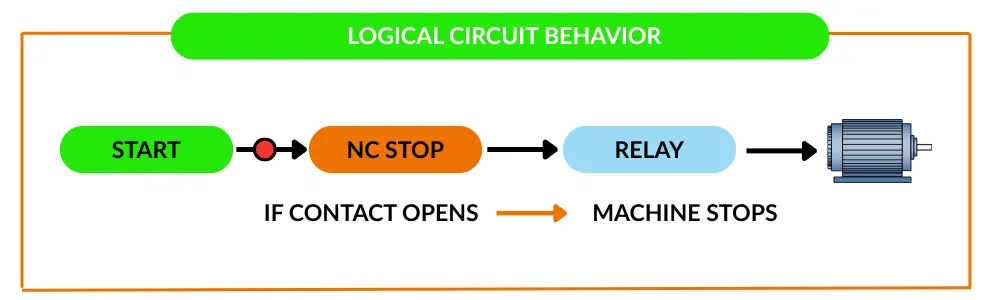

Logical View of a Typical Emergency Stop Circuit

In a basic control circuit:

- Power flows through the NC emergency stop contact.

- The contact feeds the control relay or contactor coil.

- A start button energizes the circuit.

- The relay maintains operation using a holding contact.

If the emergency stop opens:

- Control power is removed.

- Relay drops instantly.

- Motor power is cut.

- Machine stops safely.

Even if PLC logic freezes or software fails, the hardwired emergency stop still functions independently.

Redundancy Using Dual NC Contacts

Many industrial emergency stop push buttons include two NC contacts.

This improves safety further:

- One contact feeds channel A of a safety relay.

- The second contact feeds channel B.

- Both channels must agree for operation.

- Any mismatch triggers shutdown and fault indication.

This dual-channel design supports higher safety integrity levels.

Common Field Mistakes to Avoid

Even with good design standards, mistakes still happen:

- Wiring NO instead of NC during installation.

- Bypassing emergency stop for testing and forgetting to restore.

- Poor terminal tightening causing intermittent faults.

- Using low-quality push buttons.

- Ignoring alarm indications from safety circuits.

Regular inspection and training help avoid these issues.

What we learn today?

The emergency stop button is one of the most critical safety devices in any industrial system. Using Normally Closed contacts ensures fail-safe operation, fast response, easy fault detection, and compliance with safety standards.

Once this logic is clearly understood, it becomes obvious why NC contacts are always preferred in safety circuits. It is not just a convention it is a fundamental safety philosophy.

For anyone working in instrumentation, automation, maintenance, or design, mastering emergency stop logic is an essential professional skill.

English

English Deutsch

Deutsch Indonesia

Indonesia