1. Understanding the Functional Role of Manual Shut Off Valves

Manual shut off valves play a crucial role in controlling the flow of liquids and gases in piping systems. Unlike automated valves, they rely on direct human operation to stop or allow flow, providing immediate control during maintenance, emergencies, or routine system operations. These valves are valued for their simplicity, reliability, and the ability to provide a positive shutoff without dependence on external power sources. Correct selection and installation are essential to ensure that these valves can handle the specific pressure, temperature, and chemical properties of the system fluid.

2. Types of Manual Shut Off Valves and Their Applications

2.1 Gate Valves

Gate valves are designed for on/off service, featuring a rising or non-rising stem that controls a flat gate. They are suitable for systems requiring full flow with minimal pressure drop. Gate valves are commonly used in water treatment plants, oil pipelines, and chemical processing where flow needs to be completely isolated without throttling. Their construction allows for high-pressure handling and durability, though they are slower to operate compared to other valve types.

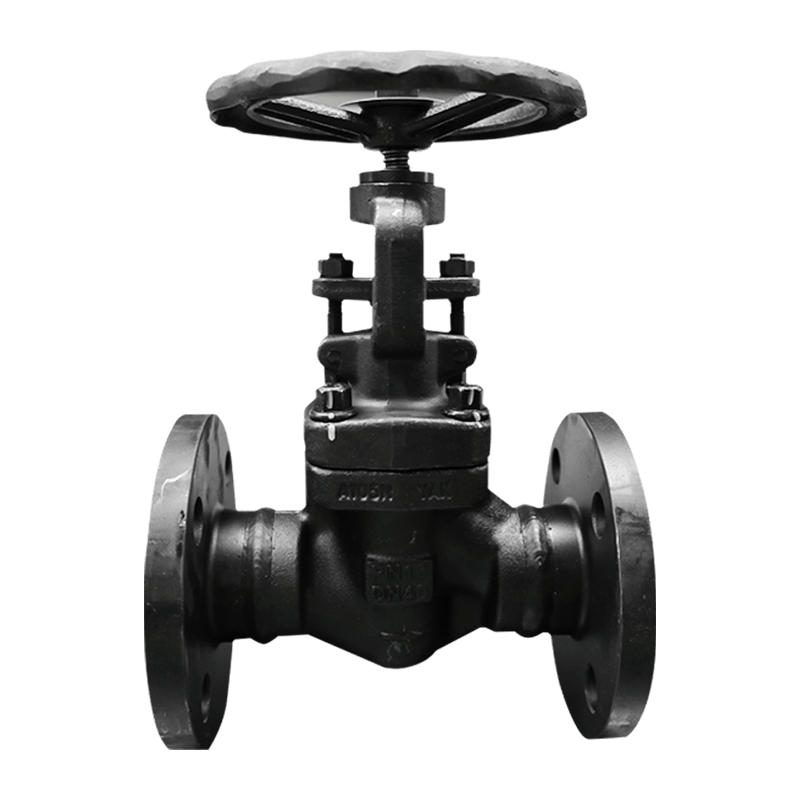

2.2 Globe Valves

Globe valves provide better throttling capabilities than gate valves, allowing precise flow control in addition to isolation. The internal disc moves perpendicularly to the flow, providing fine adjustment. These valves are ideal for systems where flow regulation is critical, such as in steam lines, chemical injection processes, and cooling water circuits. Proper stem lubrication and periodic seat inspection are essential to maintain their performance and prevent leakage.

2.3 Ball Valves

Ball valves feature a spherical closure element with a hole through the center, allowing quick opening and closing. They offer excellent sealing and are highly reliable for gas and liquid isolation. These valves are widely used in residential plumbing, industrial gas lines, and process systems where quick shutoff is required. Full-bore ball valves minimize flow resistance, while reduced-bore versions are suitable for applications where system cost and space are considerations.

2.4 Butterfly Valves

Butterfly valves utilize a rotating disc to control flow and are preferred in large-diameter piping systems. Manual operation is straightforward, and the valve provides a compact and cost-effective solution. They are commonly used in HVAC systems, water distribution networks, and fire protection piping. Proper alignment and sealing of the disc are critical to prevent leakage and maintain operational efficiency.

3. Material Selection and Pressure Considerations

Manual shut off valves are manufactured from a variety of materials to withstand different pressures, temperatures, and chemical exposures. Common materials include:

- Brass: Suitable for residential water and low-pressure applications.

- Stainless Steel: Corrosion-resistant and ideal for chemical and food-grade applications.

- Carbon Steel: High-pressure systems, industrial pipelines, and steam lines.

- PVC or CPVC: Non-corrosive and lightweight, suitable for chemical and water applications.

Selecting the correct material ensures long-term durability and safe operation under the designated pressure rating. Valves must also be rated according to the system’s maximum operating pressure and temperature, with appropriate safety margins.

4. Installation Best Practices for Manual Shut Off Valves

Proper installation is key to achieving optimal performance and longevity. Key considerations include:

- Ensure correct orientation: Some valves, such as globe valves, have directional flow requirements.

- Provide adequate space for handwheel or lever operation, especially for large valves.

- Use proper gaskets and sealants compatible with the fluid and temperature.

- Verify that valve bodies are supported to avoid pipe stress and misalignment.

5. Maintenance and Troubleshooting Strategies

Manual shut off valves require regular maintenance to ensure reliable operation. Maintenance practices include lubricating the stem, inspecting the sealing surfaces, and tightening packing glands. Periodic operation helps prevent sticking or corrosion. Common issues and solutions include:

- Leakage: Check and replace worn seals or packing.

- Difficulty in operation: Lubricate the stem and check for misalignment or debris.

- Corrosion: Use corrosion-resistant materials and inspect the valve body regularly.

Preventive maintenance schedules and documentation ensure that valves are always ready for emergency isolation or system maintenance.

6. Safety Considerations in Manual Valve Operation

Manual shut off valves are often critical safety components. Operators must be trained to recognize the correct operating procedures, including the proper sequence of opening and closing to avoid water hammer, pressure surges, or accidental discharge. Using lockout-tagout (LOTO) practices is essential in industrial systems to prevent unintentional operation during maintenance. Additionally, ensuring valves are clearly labeled and accessible improves safety and operational efficiency.

7. Advantages and Limitations of Manual Shut Off Valves

Manual shut off valves offer several advantages, including:

- Simple construction and low cost.

- Reliable isolation without reliance on electricity or pneumatic power.

- Easy to repair and maintain on-site.

However, they also have limitations. Manual operation requires human presence, which may not be feasible in hazardous or remote locations. In addition, frequent operation can cause wear, and the speed of shutoff is slower than automated alternatives. Balancing the benefits with application requirements is essential for effective system design.

8. Conclusion: Optimizing the Use of Manual Shut Off Valves

Manual shut off valves remain a cornerstone in fluid control systems due to their simplicity, reliability, and versatility. Understanding the different types, material considerations, installation best practices, and maintenance requirements ensures optimal performance and safety. Proper training, regular inspection, and adherence to operational guidelines enhance the effectiveness of these valves, making them a critical component in both industrial and residential applications.

English

English Deutsch

Deutsch Indonesia

Indonesia