In industrial conveying systems, wear, corrosion, and clogging pose three major challenges to pipeline valves. Particularly when handling media such as slurries, powders, and coarse particles, traditional valves often suffer from short service life and frequent failures, resulting in reduced production efficiency and high maintenance costs. Addressing this industry-wide challenge, VATTEN Valves has meticulously engineered the VATTEN Heavy-Duty Actuated Pinch Valve. With its exceptional wear and corrosion resistance combined with a unique design, it serves as an ideal solution for isolation and control functions in harsh operating conditions.

Core Product Advantage: Engineered for Durability and Reliability

The design philosophy of the VATTEN Heavy-Duty Actuated Pinch Valve originates from a profound understanding of industrial application challenges:

Full Bore Design,Unrestricted Flow

Problem Solved: Traditional valves with complex flow paths are prone to media accumulation and clogging, particularly when handling slurries and fibrous materials.

VATTEN Solution: When fully open, the valve provides a smooth, straight-through flow path consistent with the pipeline, featuring minimal pressure loss. This design entirely eliminates clogging risks, ensuring continuous and stable system operation.

Central-Line Shut-off Technology Significantly Extends Sleeve Service

Problem Solved: Eccentric compression during closure causes uneven sleeve wear and localized premature failure.

VATTEN Solution: Our unique centerline symmetrical compression technology ensures uniform stress distribution across the sleeve, promoting even wear patterns and elevating sleeve service life to new levels.

Sole wearing part: Replaceable specialized valve sleeve

Problem Solved: Traditional valve failures require complete valve replacement, resulting in substantial costs and extended downtime.

VATTEN Solution: Our design ensures only the rubber sleeve contacts the medium, making it the sole wearing part. When wear occurs, simply replacing the sleeve significantly reduces spare parts inventory costs and maintenance time, delivering economic efficiency.

Powerful self-cleaning function, no clogging

Problem Solved: Solid particles in the medium tend to crystallize and solidify inside the valve cavity, causing operational failure.

VATTEN Solution: Each time the valve sleeve closes under pressure, its elastic deformation causes any crystalline or granular debris adhering to its surface to automatically detach and be carried away by the medium flow.

Multiple material options for handling complex media

Problem Solved: The corrosive and abrasive nature of media, along with specialized process requirements (e.g., food-grade applications), make it challenging for a single material to meet all demands.

VATTEN Solution: We offer a diverse range of valve sleeve materials, including natural rubber, nitrile rubber, EPDM rubber, fluorocarbon rubber, and Hypalon, enabling precise selection based on temperature, wear resistance, and corrosion resistance. This caters to diverse needs—from strong acids and alkalis to food slurries.

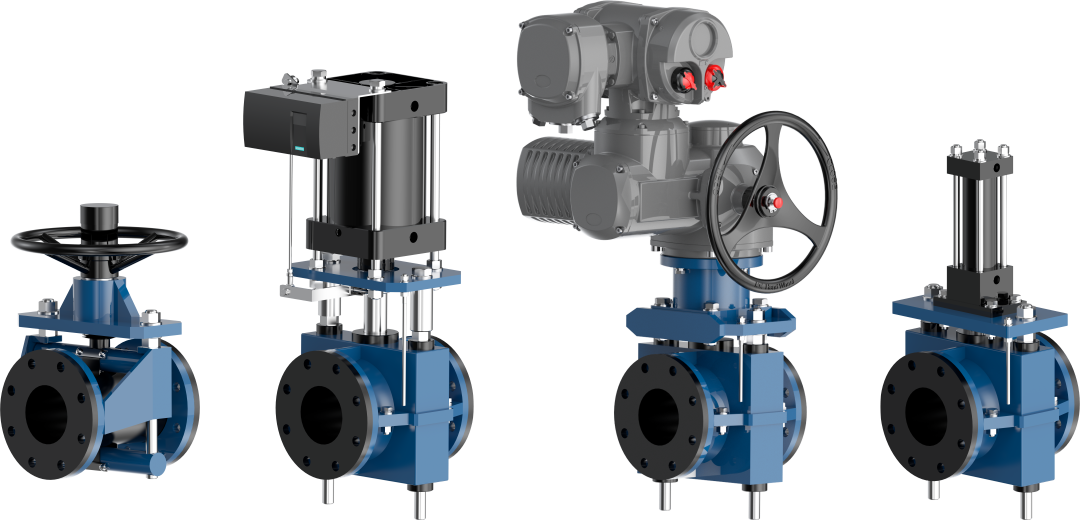

Rugged Heavy-Duty Actuated Design, Extended Maintenance Intervals

Problem Solved: The strength of the actuator is insufficient, making it prone to damage under frequent or high-pressure differential operations.

VATTEN Solution: The heavy-duty actuated mechanism features a robust structure. It can endure high-frequency operations and high-pressure working conditions. This significantly extends the maintenance service interval and reduces unplanned outages.

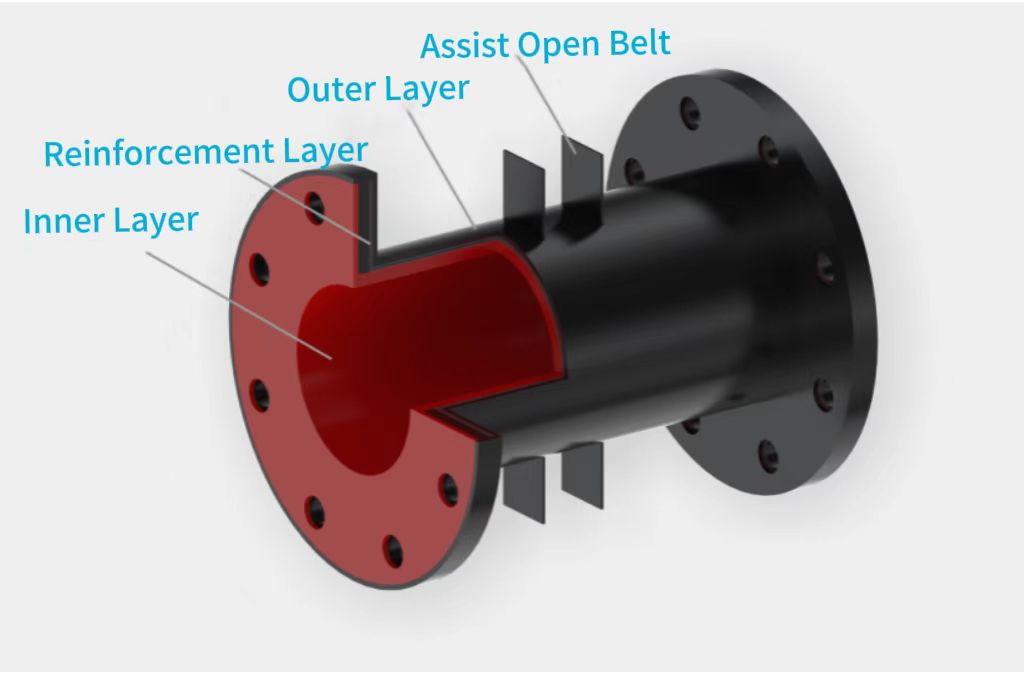

Excellence at the Core: Crafted with Precision Rubber Valve Sleeves

The sleeve is the "heart" of the pinch valve, whose quality directly determines valve performance. At VATTEN, we devote profound expertise and craftsmanship to it:

- Multi-layer Composite Structure: Each valve sleeve consists of an inner layer, reinforcement layer, outer layer, and Assist Open Belt.

- Inner Layer: Formulated specifically for demanding conditions such as abrasion, corrosion, and high temperatures, it serves as the frontline defense against the medium.

- Reinforcement Layer: A unique synthetic fiber skeleton provides the valve sleeve with pressure resistance and fatigue endurance, ensuring long-term use without deformation.

- Outer Layer and Assist Open Belt: Protects the valve body and ensures complete, rapid opening under any conditions, preventing “sticking” phenomena.

- Precise Selection Support: We provide comprehensive material application guidelines. For instance, natural rubber suits highly abrasive grinding materials; fluororubber handles strong acids and hydrocarbons; food-grade butyl rubber is specifically engineered for brewing and pharmaceutical industries. Each sleeve features a traceable serial number, guaranteeing quality.

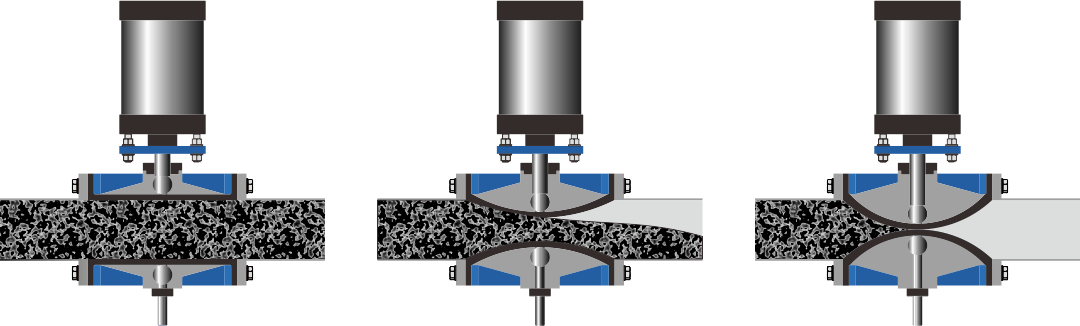

Working Principle: Simple Yet Sophisticated

The working principle of the VATTEN pinch valve is intuitive and efficient:

Open: The valve fully opens, the sleeve returns to its original position, and the flow path is unobstructed.

Close: The drive mechanism (manual, pneumatic, or electric) pushes two clamping rods, precisely compressing the resilient sleeve along the centerline to achieve an airtight seal. Even when solid particles are present in the medium, they are tightly enclosed and blocked.

Wide Range of Applications: Where Performance Speaks for Itself

The VATTEN Heavy-Duty Actuated Pinch Valve has proven their value in numerous demanding industrial sectors worldwide:

- Power Generation: Resists corrosion and abrasion from limestone slurry in FGD flue gas desulfurization systems; demonstrates exceptional wear resistance in coal handling equipment and fly ash control.

- Wastewater Treatment Plants: Reliably controls raw sewage and sludge discharge pipelines without clogging; handles complex chemical environments in flotation tanks and similar applications.

- Mining and Metallurgy: Handles tailings processing, slurry conveyance, and flotation control with ease, managing highly concentrated, abrasive media.

- Chemical Process Control: Withstands diverse corrosive and abrasive materials—from strong acids/alkalis to organic solvents—with material science providing good protection.

- Other Industries: Highly valued in pulp and paper, food and beverage, brewing, construction materials, and cement sectors for its full bore design, easy cleaning, and compliance with sanitary standards.

The VATTEN Heavy-Duty Actuated Pinch Valve is not only a product, but also a comprehensive system solution for industrial fluid handling challenges. With its exceptionally long service life, minimal maintenance requirement, and outstanding operational reliability, it is increasingly becoming the preferred choice for engineers in demanding conditions.

If you are struggling with valve wear, clogging, and frequent maintenance issues, please contact us. VATTEN's expert team will provide you with the suitable valve selection and customized solutions to make your production process smoother and more cost-effective!

English

English Deutsch

Deutsch Indonesia

Indonesia