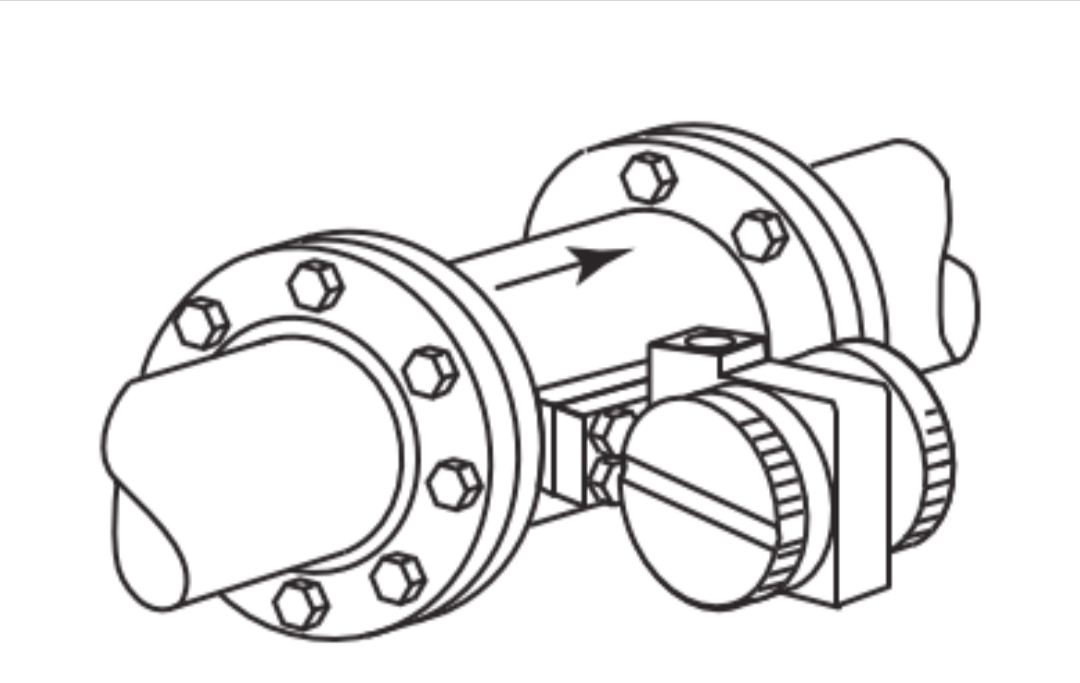

A vortex flowmeter is designed and manufactured based on the Karman vortex street theory, primarily used for measuring the flow of various clean fluids such as gases, liquids, and steam. Vortex flowmeters feature low-pressure loss, a wide measurement range, and high accuracy. When measuring the volumetric flow rate of fluids, they are almost unaffected by changes in parameters such as fluid density, pressure, temperature, and viscosity. With no moving mechanical parts, they offer high reliability and require low maintenance. Nowadays, vortex flowmeters from various manufacturers can integrate temperature compensation, enabling direct temperature compensation for gas/steam measurements. Vortex flowmeters have become one of the universal flow measurement instruments and are widely used in process industries.

Vortex flowmeters typically achieve an accuracy of 1% for gas/steam measurement and 0.75% for liquid measurement. However, if installed improperly, the measurement accuracy can be significantly compromised.

Let's discuss the installation of vortex flowmeters:

1.The installation location should be away from pipes subject to mechanical vibration and impact.

2.The flowmeter must be installed in a location that ensures the pipe is completely filled to achieve normal measurement.

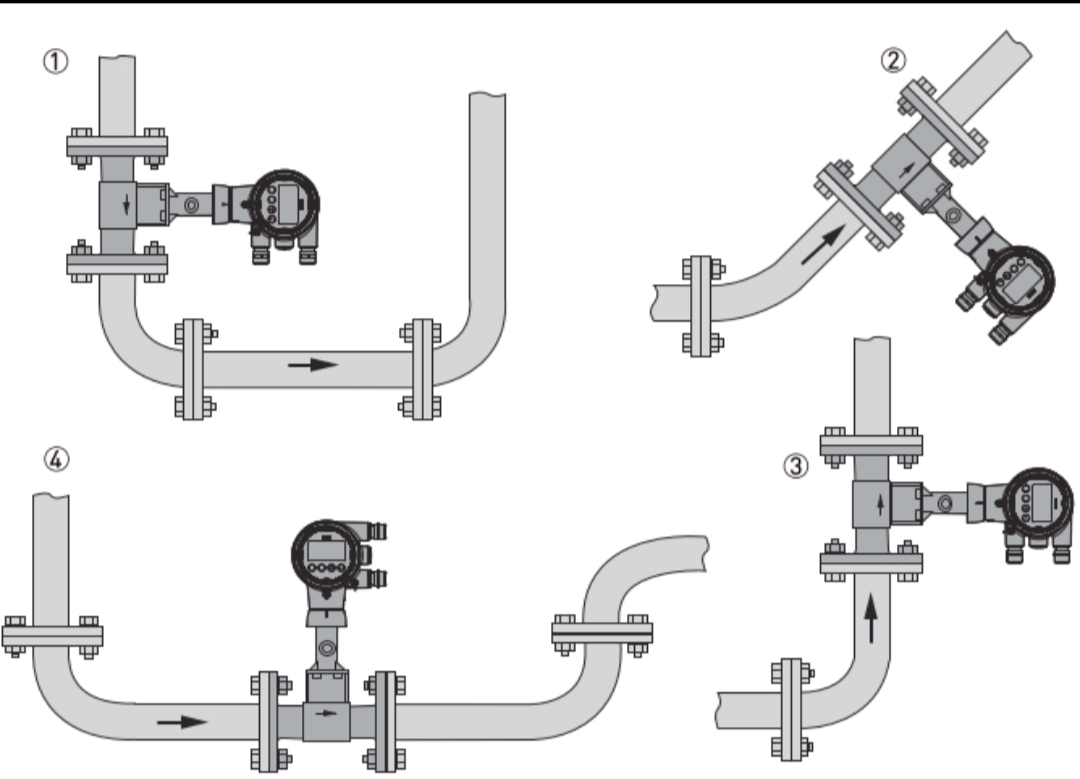

For liquid applications, the flowmeter should not be installed at high points. The following installation positions are recommended:

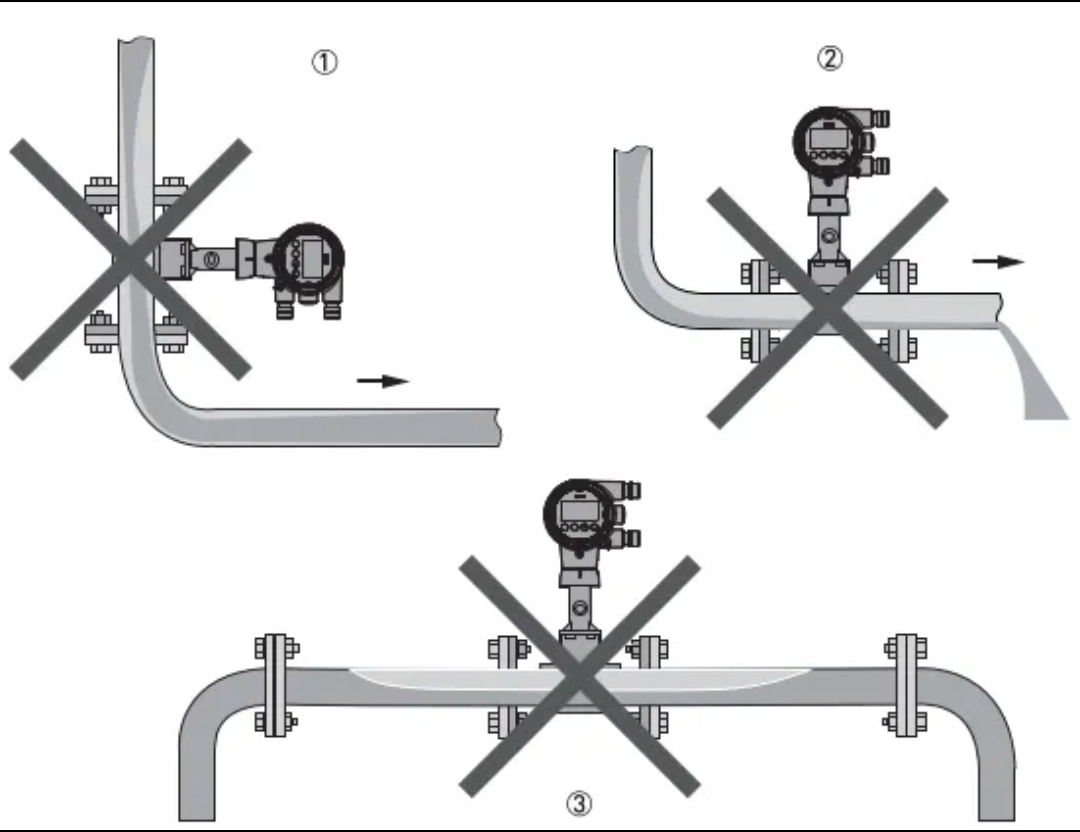

The following installation positions are not recommended for liquid applications:

For gas/steam applications, the pipeline is always full of gas. Therefore, the flowmeter can be installed in vertical upward flow, vertical downward flow, or horizontal orientations. However, it must not be installed at low points. The recommended installation positions are:

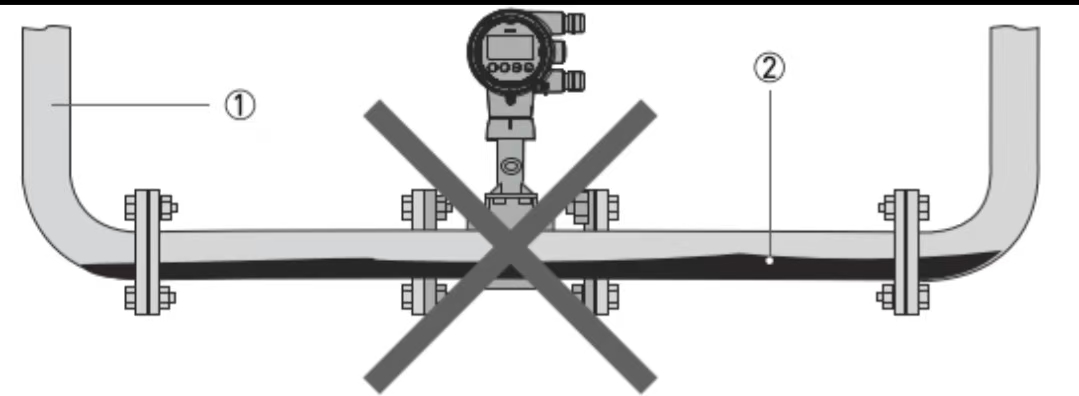

For gas/steam applications, low points may accumulate liquid and should not be selected for installation:

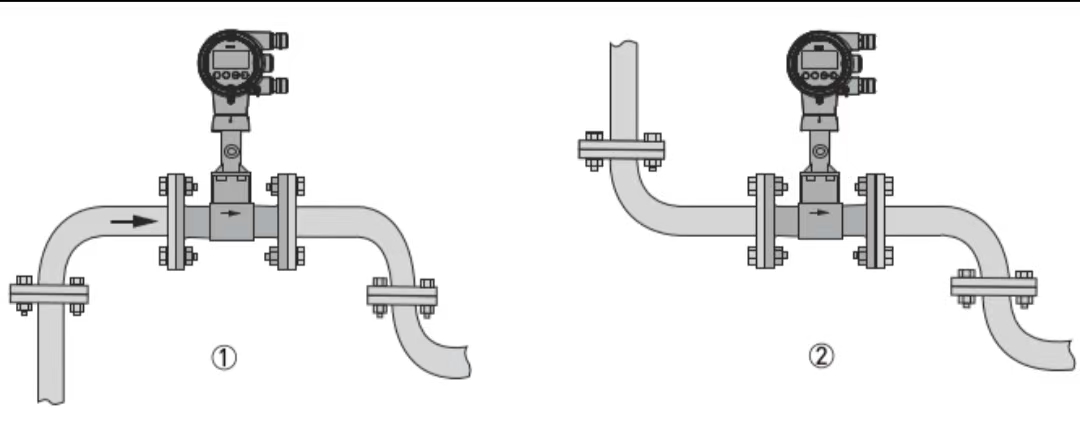

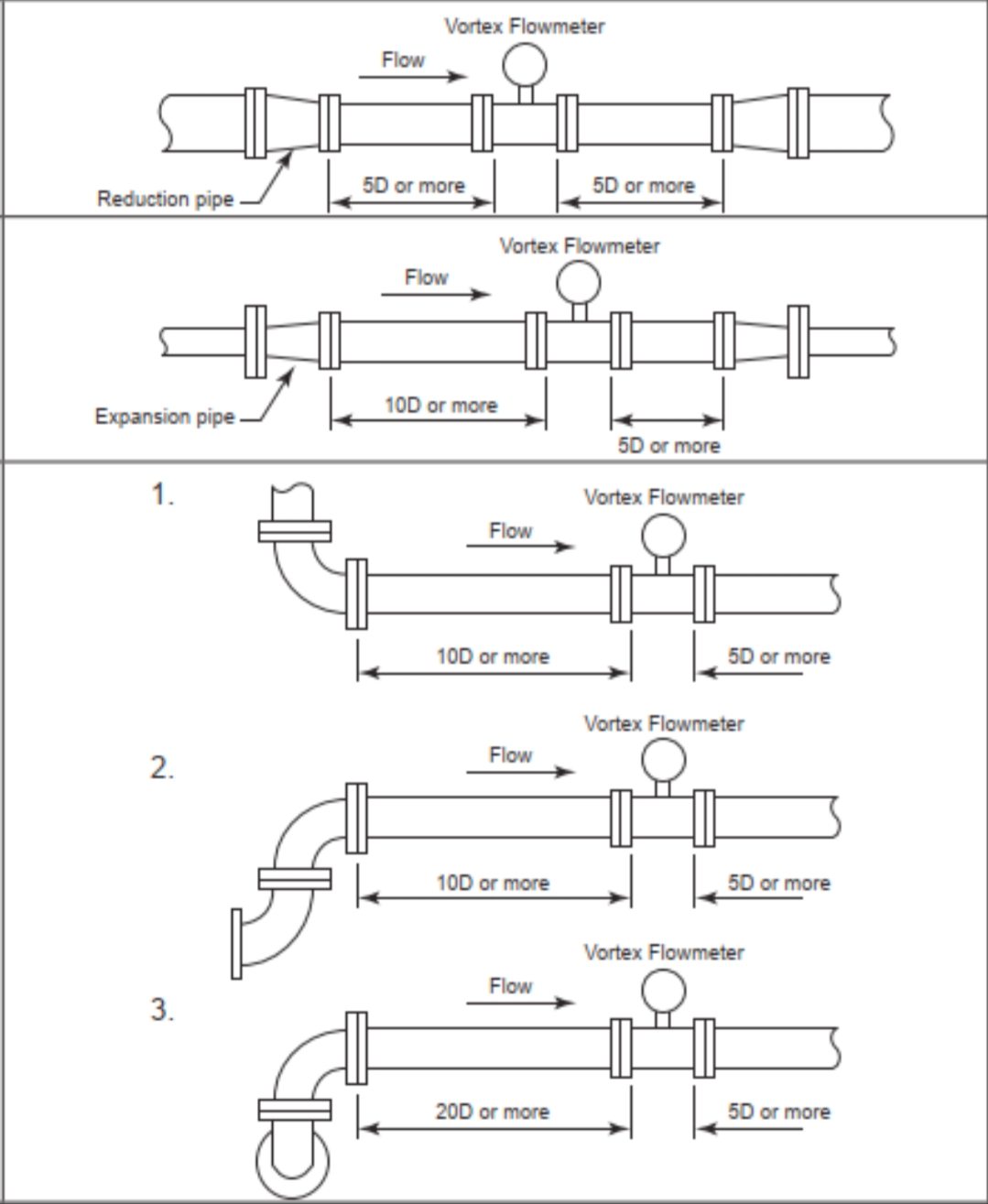

3.Straight pipe sections upstream and downstream (if temperature and pressure instruments are required, they should be installed downstream of the flowmeter. The downstream instruments should also be located outside the straight pipe section. The recommended arrangement order for multiple instruments is: flowmeter, pressure transmitter, temperature transmitter). Generally, refer to the straight pipe length requirements specified in the manufacturer’s product sample (or the common guideline of 15D upstream and 5D downstream as per instrument manuals). Inform the piping engineering team about the upstream and downstream straight pipe requirements for the vortex flowmeter in advance. Once the instrument manufacturer is selected, the installation requirements must be reconfirmed according to the manufacturer’s specifications.

4.When measuring media with high temperatures, manufacturers typically supply split-type vortex flowmeters. For integrated vortex flowmeters, the orientation of the transmitter should be determined based on the medium's temperature. For instance, when measuring high-temperature steam, the transmitter should be oriented sideways or downward (some manufacturers do not recommend downward installation, as liquid may ingress into the transmitter head).

English

English Deutsch

Deutsch Indonesia

Indonesia