What are the causes of reduced sealing performance in control valves?

How to solve this problem?

A:Reduced sealing performance in control valves leads to media leakage, which compromises process control accuracy and operational safety. The root causes can be categorized into two primary types: internal leakage and external leakage. Therefore, targeted analysis and solutions are required.

01.Internal leakage

The most common cause is failure of the valve core and seat sealing surfaces. On one hand, this may result from prolonged erosion of the valve core/seat by high pressure differentials and particulate-laden media, leading to scratches, pitting, and cavitation[1] erosion on the sealing surfaces. On the other hand, it could stem from poor compatibility of the sealing structure, such as deformation of soft seals under high-pressure conditions or corrosion of sealing surfaces due to failure to select corrosion-resistant materials for highly corrosive media.

02.External leakage

The causes primarily fall into two main categories: packing seal failure (e.g., aging or wear of packing, improper installation) and seal failure at valve body connections (e.g., gasket aging, casting defects in the valve body).

In response to the above potential causes, targeted maintenance can be performed on control valves with reduced sealing performance.

(1)Replace aged or damaged packing. Select the appropriate packing type based on the media characteristics and operating conditions, such as graphite ring packing for high‑temperature media or PTFE packing for corrosive media.

(2)Reinstall the packing correctly. Ensure proper tightening force and that the packing is evenly seated against the stem and packing chamber.

(3)Inspect the valve stem surface. If scoring or corrosion is found, repair or replace the stem.

(4)If there are defects in the sealing structure, such as a damaged stuffing box, repair or replace the relevant components of the upper bonnet.

[1]Cavitation: When liquid flows through a throttling element such as a control valve, the local pressure drops to or below the saturated vapor pressure at the current temperature, causing the liquid to vaporize and form bubbles. As the fluid then moves to a downstream region of higher pressure, these bubbles collapse rapidly, generating intense shock waves and micro‑jets. This phenomenon leads to equipment noise, vibration, and cavitation erosion damage.

Why does noise occur during the operation of a control valve?

How to maintain and solve this problem?

A:When noise occurs during the operation of a control valve, we should first identify its type and root cause. The noise generated by control valves primarily falls into two categories: fluid-dynamic noise and mechanical noise.

Fluid-dynamic noise

Flow-induced noise is the most common type, which can be further categorized into three subtypes: cavitation noise, flashing noise, and turbulence and vortex noise.

Cavitation noise occurs when the pressure differential across a valve becomes excessive, causing the fluid pressure at the throttling point to fall below the saturated vapor pressure. This leads to the formation and subsequent collapse of bubbles, generating high-frequency noise accompanied by cavitation damage to the valve core.Flashing noise occurs when the fluid pressure remains below the saturated vapor pressure after throttling, creating a stable gas-liquid two-phase flow. The resulting turbulence generates noise, which is common in liquid media applications.Turbulence and vortex noise is caused by uneven flow velocity through the throttling orifice, leading to vortex shedding. This noise increases significantly when the flow velocity approaches or exceeds the speed of sound and is more prevalent in gas media.

Mechanical noise

Mechanical noise originates from two primary sources: vibration of the valve plug/stem or noise from the actuator.It refers to low‑frequency vibration noise caused by oscillations of the valve plug during low‑flow operation, or by excessive clearance due to friction between the stem and packing or wear of the guide bushing. Alternatively, noise can be transmitted to the valve body due to issues such as insufficient spring stiffness in a pneumatic diaphragm actuator, wear of the gear and rack in a piston actuator, or motor resonance in an electric actuator.For both types of noise mentioned above, mitigation can be achieved through operational adjustments and design enhancements. At the source, noise can be avoided by adjusting the pressure differential, opening degree, and flow velocity. Through design improvements, such as using corrosion- and wear-resistant materials or optimizing the valve trim geometry, noise can also be effectively reduced.

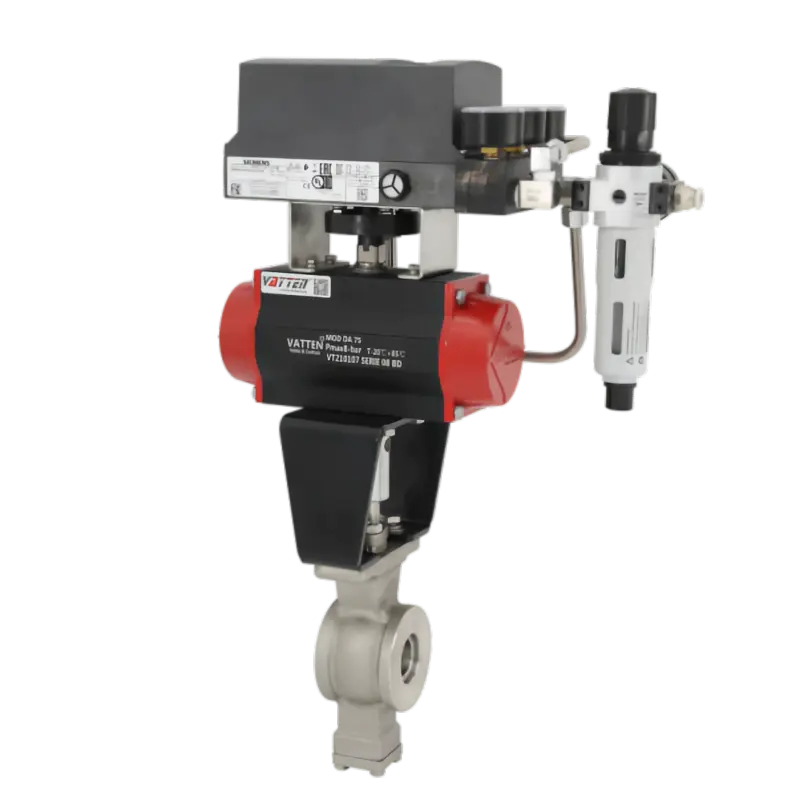

For instance, V‑port ball valves and eccentric rotary valves feature streamlined flow path designs to minimize vortex generation, while soft‑seated valve trims can absorb a portion of the turbulence‑induced noise.

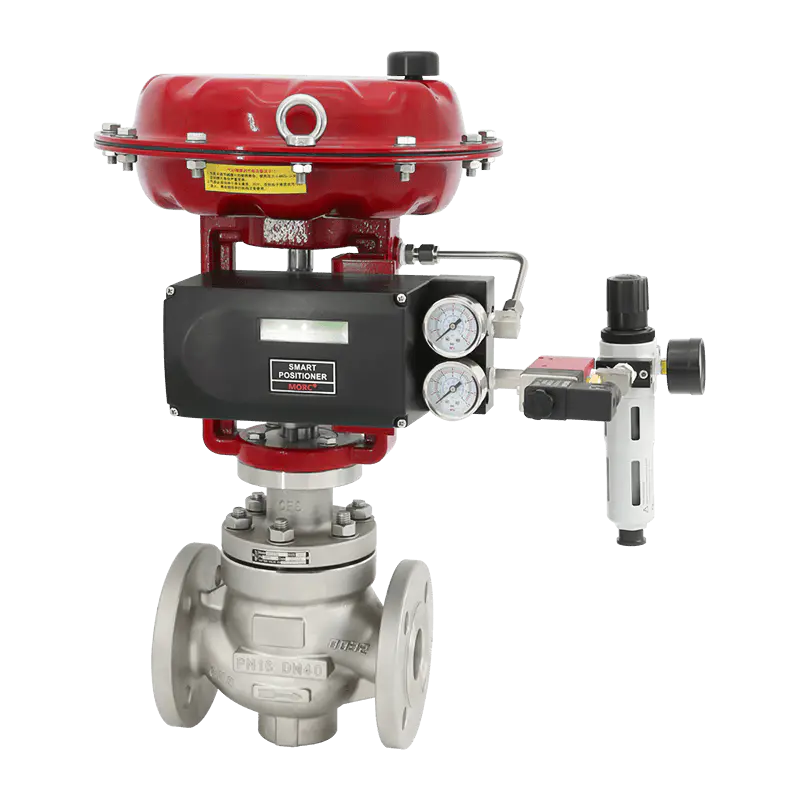

To minimize and prevent control valve failures in fluid control processes, it is essential to properly select and perform regular maintenance on the valves. This includes confirming functional requirements in advance, calculating key parameters such as pressure drop and flow rate; regularly inspecting the valve plug and seat for wear, replacing aged packing and guide bushings; performing regular blowdown for pneumatic actuators, and checking the motor and gearbox for electric actuators,and so on.

For any valve requirements, please feel free to consult VATTEN!

English

English Deutsch

Deutsch Indonesia

Indonesia