Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the control valve cannot stably maintain an appropriate position to sustain the predetermined proc...

READ MORE

Electric Ball Valves Manufacturers

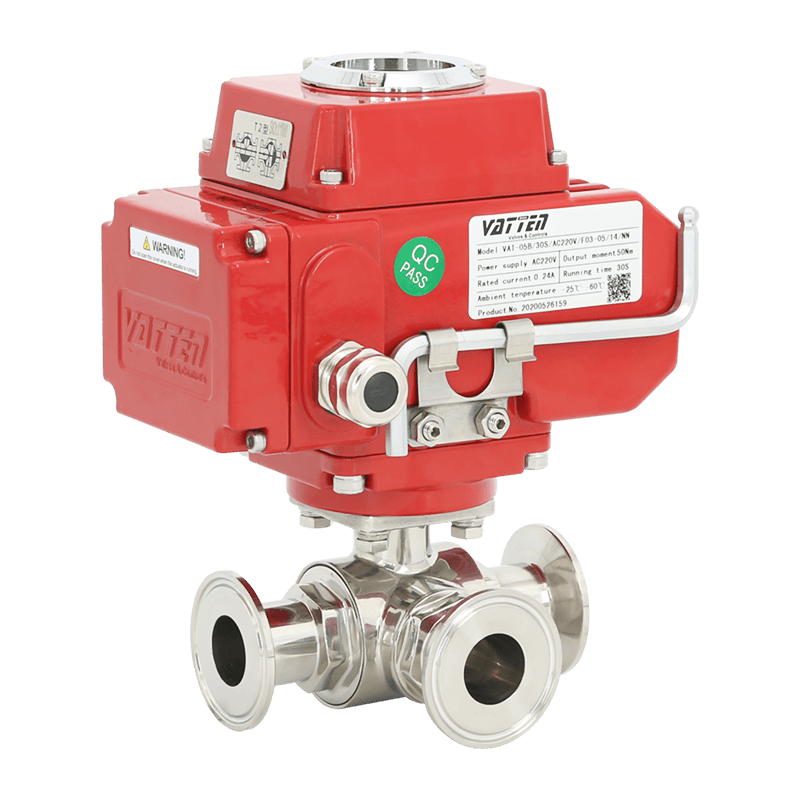

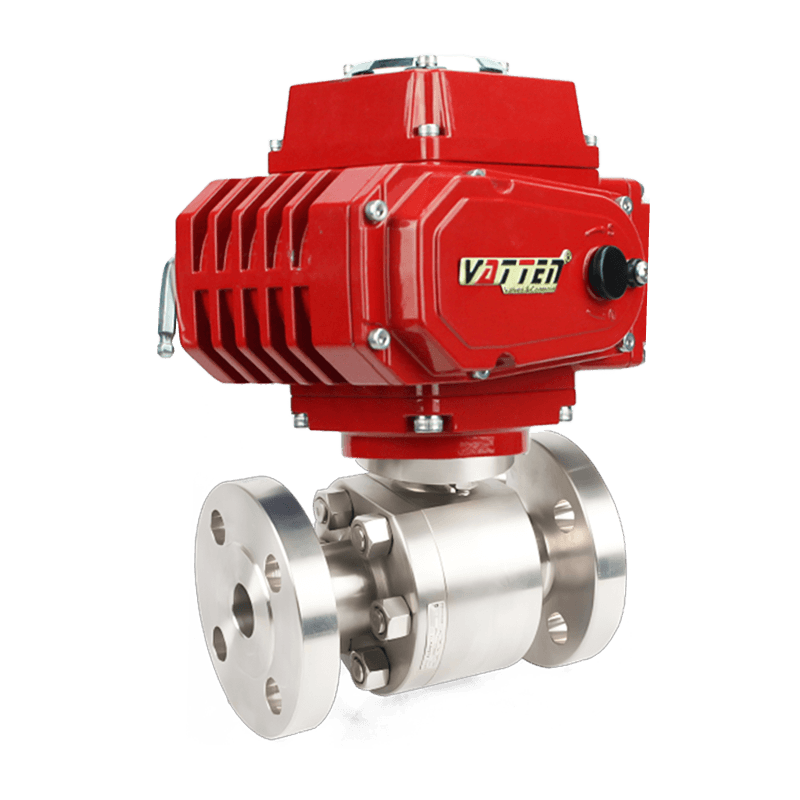

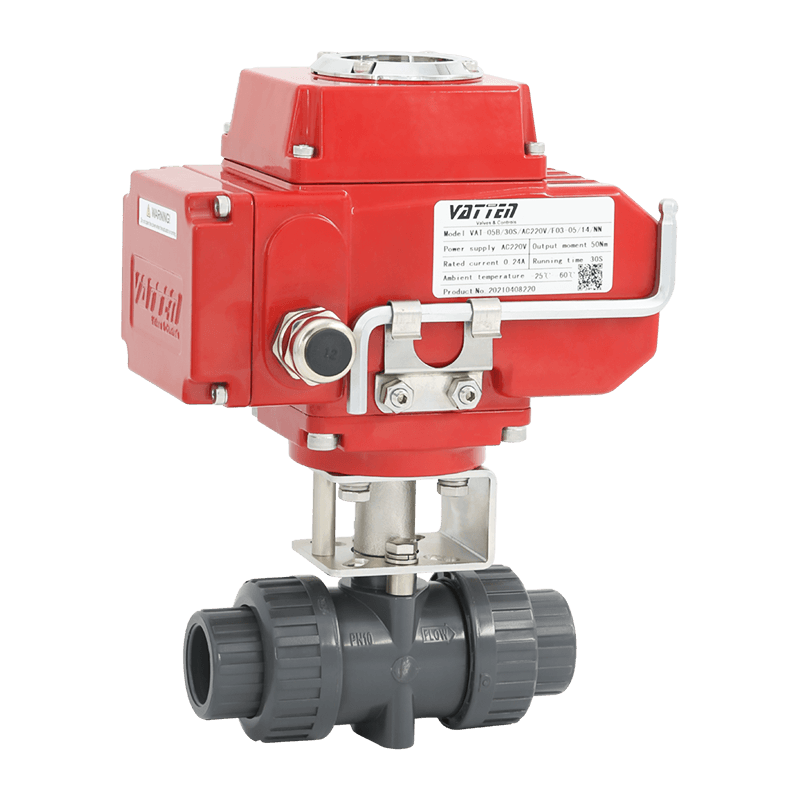

The VATTEN electric ball valve operates by driving the motor through the power supply, enabling the valve to open and close.

Our electric actuators are available in both multi-turn and angular stroke types to meet various needs.

Power supply options include AC220V, AC380V, and DC24V, allowing users to choose according to their specific requirements.

The powerful motor provides sufficient torque to ensure smooth and effortless valve operation.

We also offer explosion-proof electric actuators for safe use in hazardous environments.

The local control actuator design offers flexibility, allowing users to make adjustments based on on-site needs.

VATTEN electric ball valves are widely recognized in industries such as power plants and water treatment.

Our electric actuators provide an effective solution for situations where no air supply is available on-site

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

As Electric Ball Valves Manufacturers and Electric Ball Valves Company, the Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. Provide Custom Electric Ball Valves. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

-

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow controlled release of bulk solids, slurries, or liquids by gravity. They are a critical comp...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatically using an electric actuator that adjusts valve position based on control signals. They...

READ MORE -

Key Conclusion: Why Check Valves Are Essential in Fluid Systems Check valves are installed to allow fluid to flow in only one direction and automatically prevent reverse flow without manual intervention. Their...

READ MORE

What Safety Features Are Included in Vatten Valve Group’s Electric Ball Valves to Prevent Over-Torque or Over-Pressure?

Electric ball valves are essential components in modern industrial automation systems, providing precise control of fluid flow across a wide range of applications. However, in industries such as energy, water treatment, chemical processing, and pharmaceuticals, safety and reliability are just as important as performance. Vatten Valve Group, a globally recognized industrial automation valve enterprise originating from Saarland, Germany, addresses these concerns with robust safety features designed to prevent over-torque and over-pressure scenarios.

About Vatten Valve Group

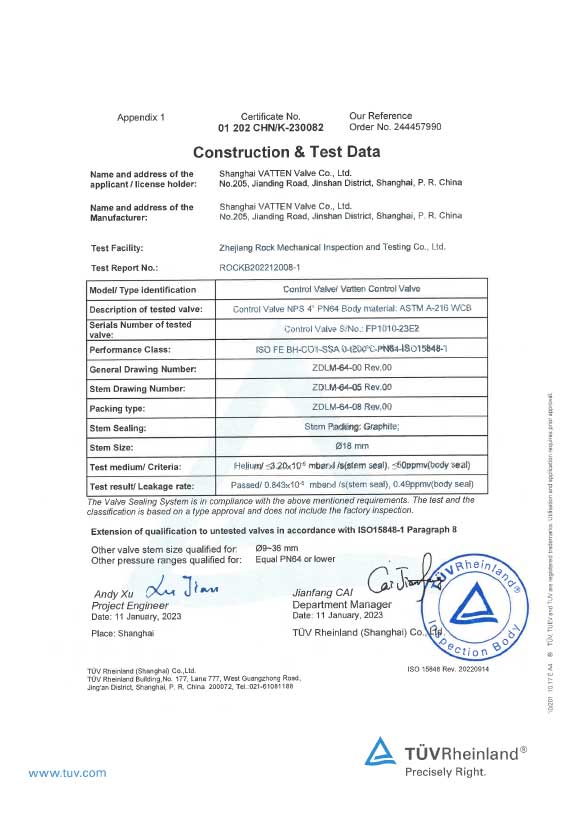

Vatten Valve Group specializes in the research, development, and manufacturing of core products including automatic control ball valves, butterfly valves, and regulating valves. With a foundation in German precision engineering, the Group leverages advanced technological expertise to deliver innovative valve solutions and professional technical support to critical industries.

The company operates four state-of-the-art manufacturing bases in Shanghai, Tianjin, Lishui, and Jiaxing, China, and maintains international branch offices in the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. This global presence ensures timely service and technical support for clients in diverse markets.

Rooted in a tradition of quality and precision, Vatten Valve Group is committed to continuous innovation, providing superior performance products, custom electric ball valve solutions, and comprehensive fluid control systems to empower industries to meet complex operational challenges.

How Vatten Electric Ball Valves Operate

Vatten electric ball valves function via a motor-driven mechanism powered by AC220V, AC380V, or DC24V, allowing the valve to open and close efficiently. The actuators are available in both multi-turn and angular stroke types, providing flexibility to match specific operational requirements. The powerful motors deliver sufficient torque to ensure smooth operation, while local control actuator designs allow for on-site adjustments.

These valves are particularly useful in applications where pneumatic air supply is unavailable, making them ideal for power plants, water treatment facilities, and chemical processing plants. Explosion-proof versions are also available for safe use in hazardous environments.

Key Safety Features

1. Over-Torque Protection

Electric ball valves can be damaged or cause system hazards if excessive torque is applied. Vatten electric actuators incorporate built-in over-torque protection, which automatically stops the actuator if the torque exceeds safe limits. This feature prevents damage to both the valve and the actuator, ensuring long-term operational reliability.

2. Over-Pressure Protection

Excessive pressure in a pipeline can compromise valve integrity and system safety. Vatten valves can be paired with pressure monitoring solutions and relief mechanisms to prevent over-pressure situations. These valves are rigorously tested to meet international pressure standards, minimizing risk in high-pressure systems.

3. Motor and Actuator Safeguards

The electric actuators are designed with integrated safety stops that prevent over-rotation. Multi-turn and angular stroke actuators are calibrated to maintain precise positioning, reducing the likelihood of mechanical stress or system failure.

4. Explosion-Proof Options

For operations in volatile or hazardous environments, Vatten offers explosion-proof electric actuators. These actuators are certified to international safety standards, providing an extra layer of protection against sparks or electrical faults that could otherwise trigger dangerous situations.

5. Manual Override and Local Control

Vatten electric ball valves feature local control capabilities, allowing operators to manually adjust the valve if necessary. This ensures continued safe operation even during unexpected system failures or electrical issues.

Applications and Industry Recognition

Vatten electric ball valves are widely used in industries where safety and reliability are critical. From chemical plants to water treatment facilities and power generation, these valves provide not only precise flow control but also peace of mind through robust safety features.

By combining German engineering precision with global manufacturing and support networks, Vatten Valve Group ensures that clients receive valves that meet both operational demands and stringent safety requirements.

Conclusion

Safety and reliability are at the core of Vatten Valve Group’s electric ball valves. With features such as over-torque protection, over-pressure safeguards, explosion-proof actuators, and manual override capabilities, these valves are engineered to prevent operational hazards while delivering precise, efficient performance. Whether for high-pressure pipelines or hazardous industrial environments, Vatten electric ball valves provide a dependable solution for modern fluid control needs.

English

English Deutsch

Deutsch Indonesia

Indonesia