Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the control valve cannot stably maintain an appropriate position to sustain the predetermined proc...

READ MORE

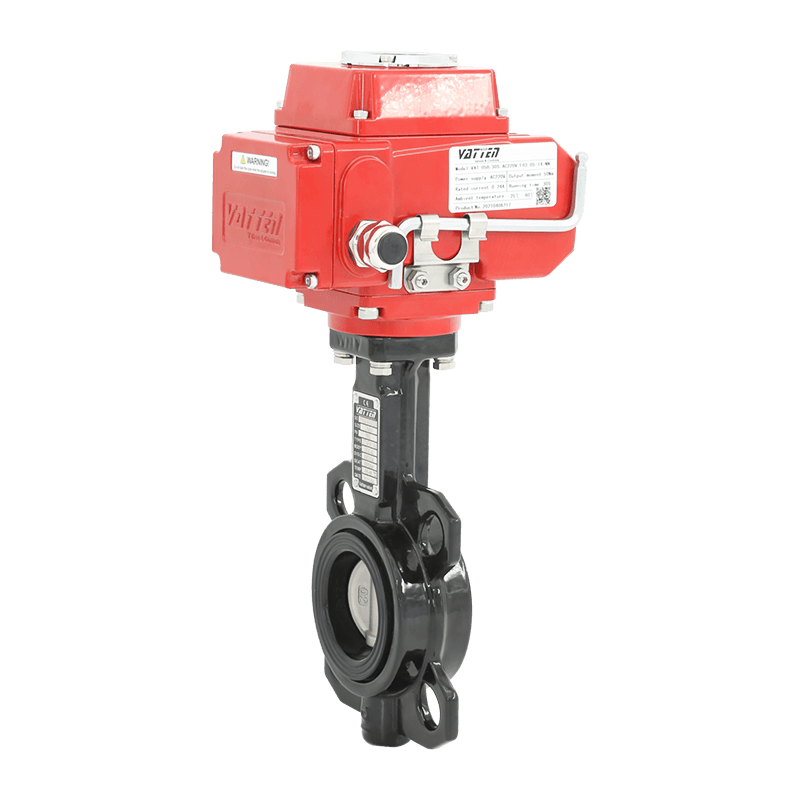

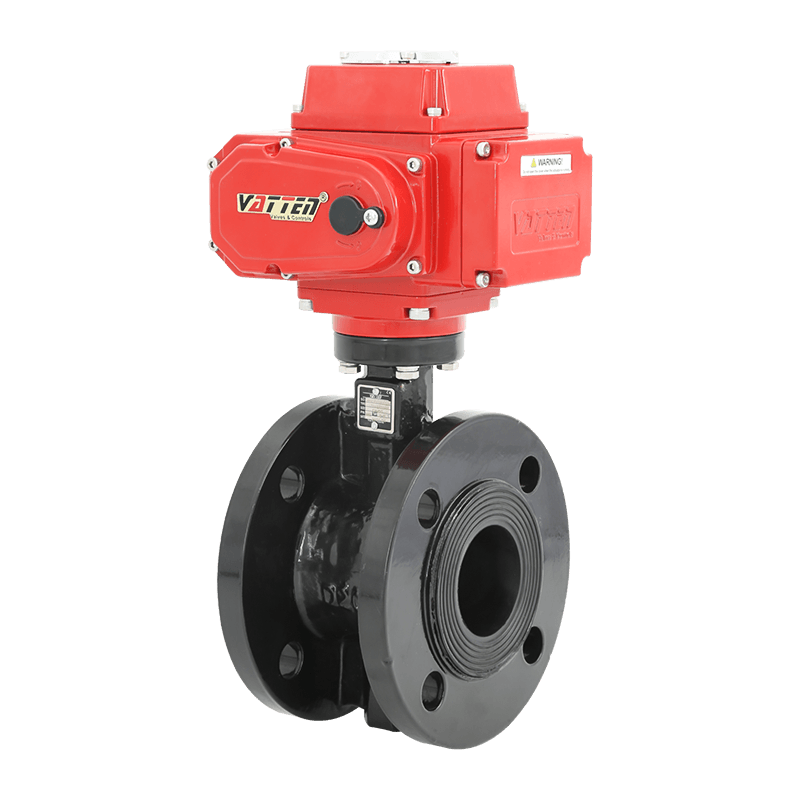

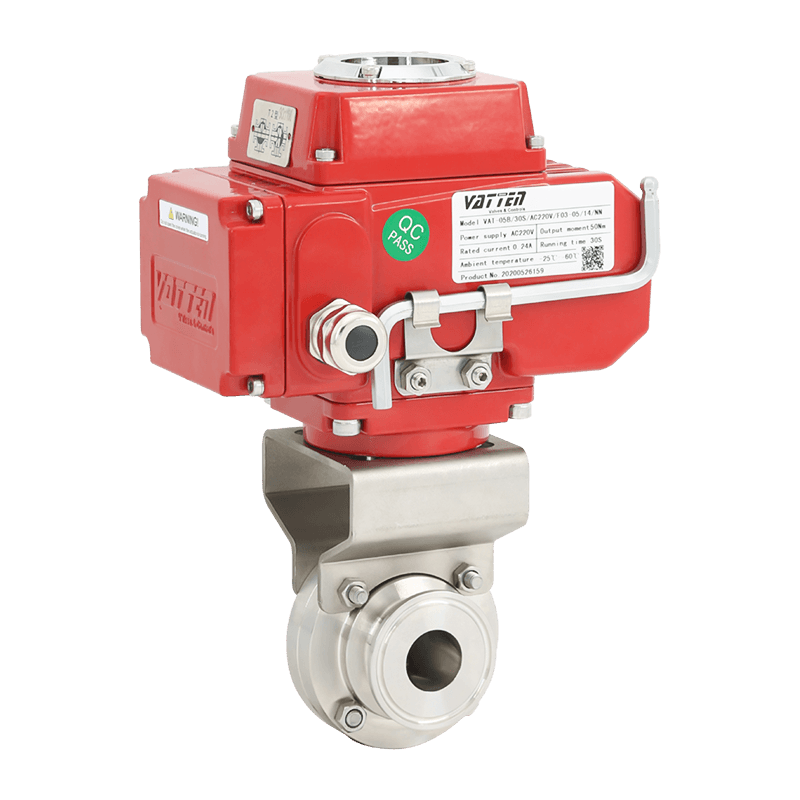

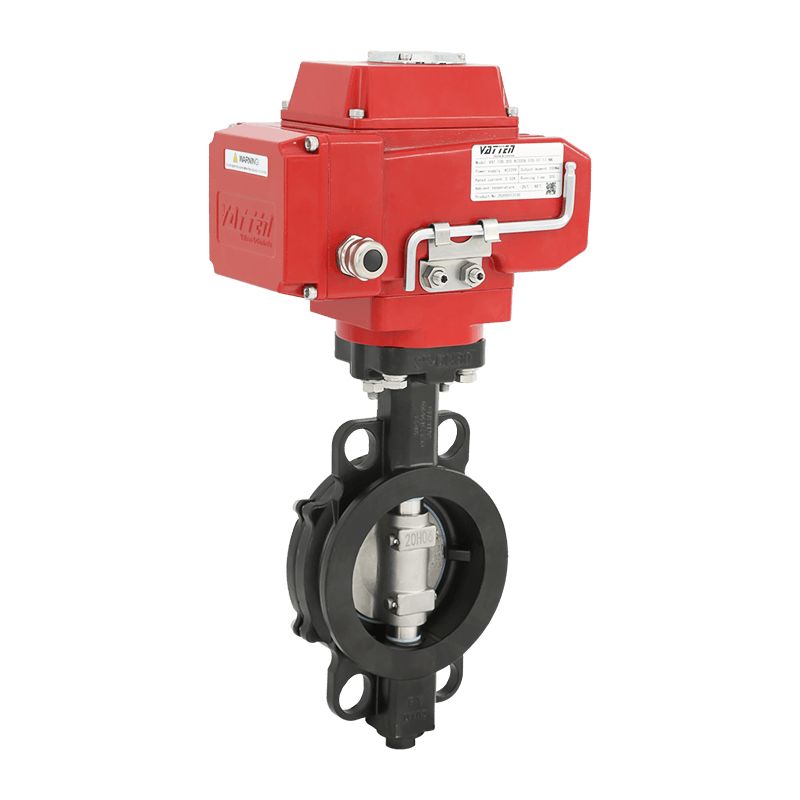

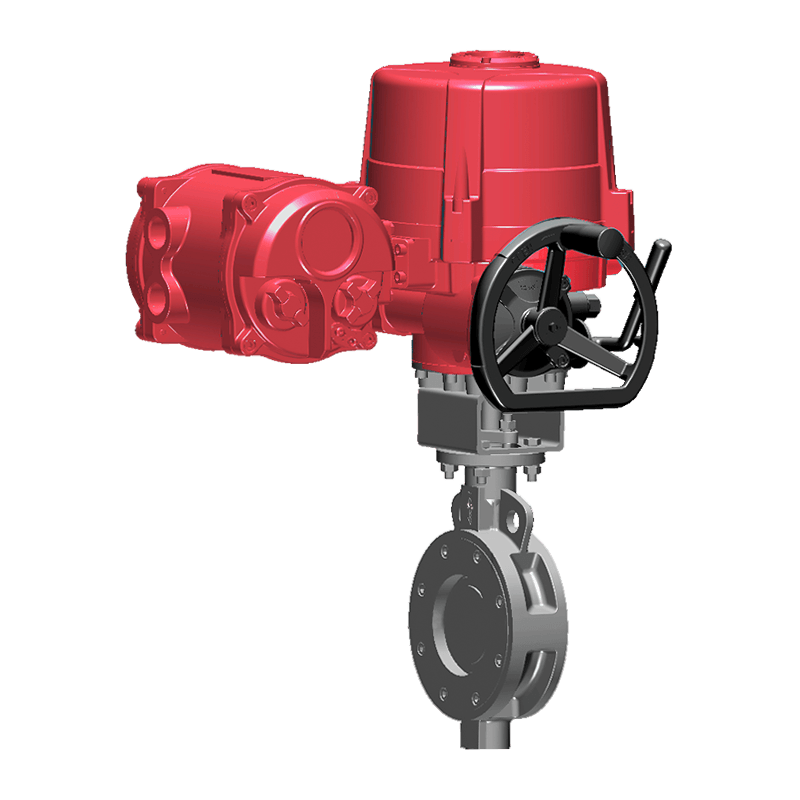

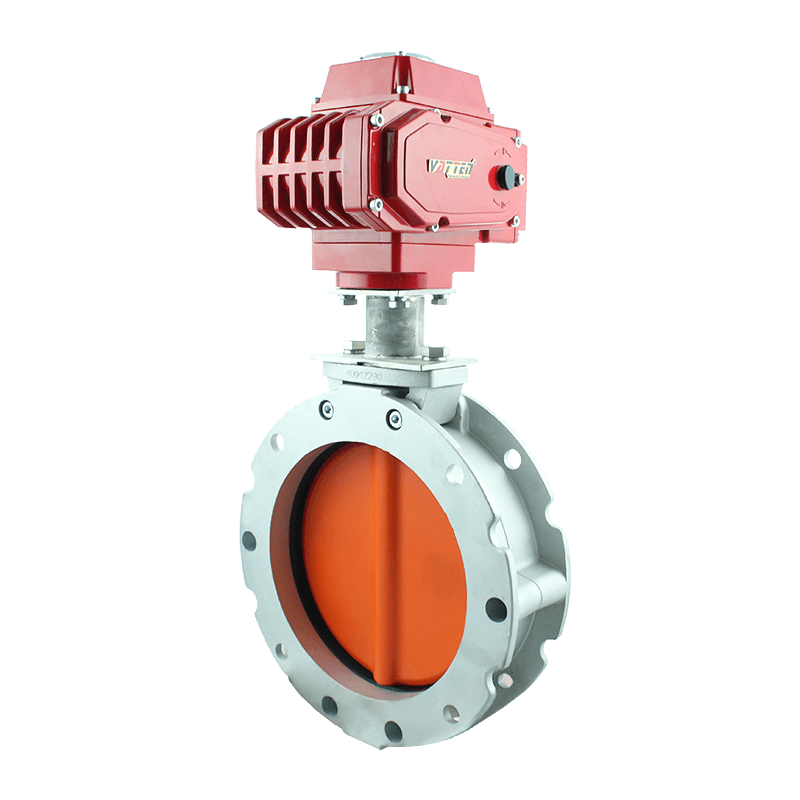

Electric Butterfly Valves Manufacturers

VATTEN electric butterfly valves are available with various connection types, including wafer, flange, and quick-installation, to suit different installation requirements.

For seawater desalination applications, we offer a variety of valve plate materials to choose from, including 316L stainless steel, 2205 duplex stainless steel, 2507 super duplex stainless steel, and aluminum bronze, all designed to meet different corrosion resistance needs.

Additionally, we provide materials such as F4 and F46, which perform excellently in environments with strong acids, strong alkalis, and severe corrosion.

Regarding the electric actuator, VATTEN electric butterfly valves are equipped with basic functions like overheat protection and local control, ensuring the reliability and safety of the equipment.

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

As Electric Butterfly Valves Manufacturers and Electric Butterfly Valves Company, the Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. Provide Custom Electric Butterfly Valves. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

-

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow controlled release of bulk solids, slurries, or liquids by gravity. They are a critical comp...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatically using an electric actuator that adjusts valve position based on control signals. They...

READ MORE -

Key Conclusion: Why Check Valves Are Essential in Fluid Systems Check valves are installed to allow fluid to flow in only one direction and automatically prevent reverse flow without manual intervention. Their...

READ MORE

What Are the Advantages of Using Electric Butterfly Valves Over Manual Valves?

Electric butterfly valves have become a preferred choice in many industrial applications due to their numerous advantages over traditional manual valves. These automated valves offer enhanced control, efficiency, and reliability, making them ideal for systems where precision and speed are essential. In this article, we will explore the key benefits of electric butterfly valves compared to manual valves, examining their design, operation, and applications in detail.

Overview of Electric Butterfly Valves

An electric butterfly valve is a type of quarter-turn valve used to control the flow of liquids, gases, or slurries within a pipeline. The valve consists of a disc mounted on a rotating shaft that can be opened or closed by rotating the actuator. The actuator is powered by electricity, which allows for automatic control and precise adjustment of the valve position. This makes electric butterfly valves highly efficient in applications requiring remote or automated control, such as in water treatment plants, HVAC systems, and industrial process control systems.

How Do Electric Butterfly Valves Work?

The operation of an electric butterfly valve is straightforward. The electric actuator, which is connected to the valve shaft, rotates the disc in the valve body to control the flow. The actuator is powered by an electric signal from a controller, which can be programmed for automatic opening and closing based on system requirements. This eliminates the need for manual adjustment and offers the benefits of remote control, automation, and precise flow regulation.

Key Advantages of Electric Butterfly Valves

1. Improved Automation and Control

One of the primary benefits of electric butterfly valves is the enhanced level of control they provide over fluid flow. Unlike manual valves, which require operators to physically turn a handle or wheel to open or close the valve, electric butterfly valves can be controlled remotely. This is particularly beneficial in systems that need precise adjustments or where manual control would be impractical due to distance or hazardous conditions.

- Remote Operation: Electric butterfly valves can be integrated with control systems, allowing operators to monitor and adjust flow remotely. This eliminates the need for manual intervention and helps streamline operations.

- Automation: With an electric actuator, these valves can be automatically adjusted based on real-time data from sensors, enabling precise flow regulation without human intervention.

- Preset Control: Electric butterfly valves can be programmed to open or close at specific times or flow rates, ensuring optimal performance in complex systems.

2. Enhanced Efficiency and Speed

Electric butterfly valves offer significant improvements in both efficiency and speed compared to manual valves. The electric actuator allows for faster opening and closing of the valve, reducing the time required for system adjustments. This is especially important in industries where fast response times are critical, such as in chemical processing, oil and gas, and water treatment.

- Faster Response Time: Electric actuators can quickly adjust the valve position, which is essential in high-speed processes where even a slight delay could impact system performance.

- Higher Precision: Electric butterfly valves can be controlled with high precision, allowing for incremental changes in flow. This level of control is difficult to achieve with manual valves, especially in complex systems with multiple variables.

- Reduced Human Error: The automated nature of electric butterfly valves minimizes the risk of human error during operation, ensuring that the valve is always in the correct position for optimal flow control.

3. Increased Safety

Electric butterfly valves offer significant safety advantages over manual valves, particularly in hazardous or hard-to-reach environments. In many industrial settings, workers may be exposed to dangerous chemicals, high pressures, or extreme temperatures when operating manual valves. Electric butterfly valves eliminate the need for physical interaction with the valve, allowing operators to control the system from a safe distance.

- Remote Control: With electric butterfly valves, operators can control flow from a safe location, reducing the risk of accidents when handling hazardous materials or operating in confined spaces.

- No Need for Manual Adjustment: In high-pressure or toxic environments, manual valve operation can be risky. Electric valves remove this danger by automating the process, preventing direct exposure to hazardous conditions.

- Fail-Safe Features: Many electric butterfly valves come equipped with fail-safe features, such as spring return actuators, which ensure that the valve will close automatically in the event of a power failure or system malfunction.

4. Reduced Maintenance Costs

Electric butterfly valves are generally more reliable and require less maintenance than manual valves. Since they are automated and have fewer moving parts than manual valves, they experience less wear and tear over time. This leads to a reduction in maintenance costs and downtime, resulting in improved system uptime and cost savings for companies.

- Longer Lifespan: With fewer mechanical components and better sealing, electric butterfly valves tend to last longer than manual valves, reducing the frequency of replacements.

- Less Frequent Maintenance: Electric actuators have fewer components that can break or wear out, leading to less frequent maintenance and fewer parts that need to be replaced.

- Lower Operating Costs: The automation of electric butterfly valves reduces the need for manual labor and minimizes the chance of costly mistakes or accidents during operation.

5. Versatility and Integration

Electric butterfly valves are highly versatile and can be integrated into a wide range of systems. These valves are available in various sizes, materials, and configurations, making them suitable for use in different industries, from water treatment to oil and gas processing. Additionally, they can be easily integrated into existing control systems, allowing for seamless automation and remote monitoring.

- Adaptability: Electric butterfly valves are available in a variety of materials such as stainless steel, cast iron, and PVC, allowing them to be used in both low and high-pressure systems.

- Easy Integration: These valves can be easily integrated into control systems, making them suitable for both new installations and retrofitting existing systems.

- Wide Range of Applications: Electric butterfly valves are used in a diverse range of industries, including HVAC, water treatment, chemical processing, and food and beverage, thanks to their adaptability and precise control capabilities.

Conclusion

Electric butterfly valves offer numerous advantages over manual valves, including improved automation, increased control, faster response times, enhanced safety, and reduced maintenance costs. These benefits make electric butterfly valves the ideal choice for many industrial applications that require precise flow control and automation. Whether you’re looking to increase efficiency in a manufacturing process, improve safety in a hazardous environment, or reduce downtime and maintenance costs, electric butterfly valves provide a reliable and cost-effective solution.

English

English Deutsch

Deutsch Indonesia

Indonesia