Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the control valve cannot stably maintain an appropriate position to sustain the predetermined proc...

READ MORE

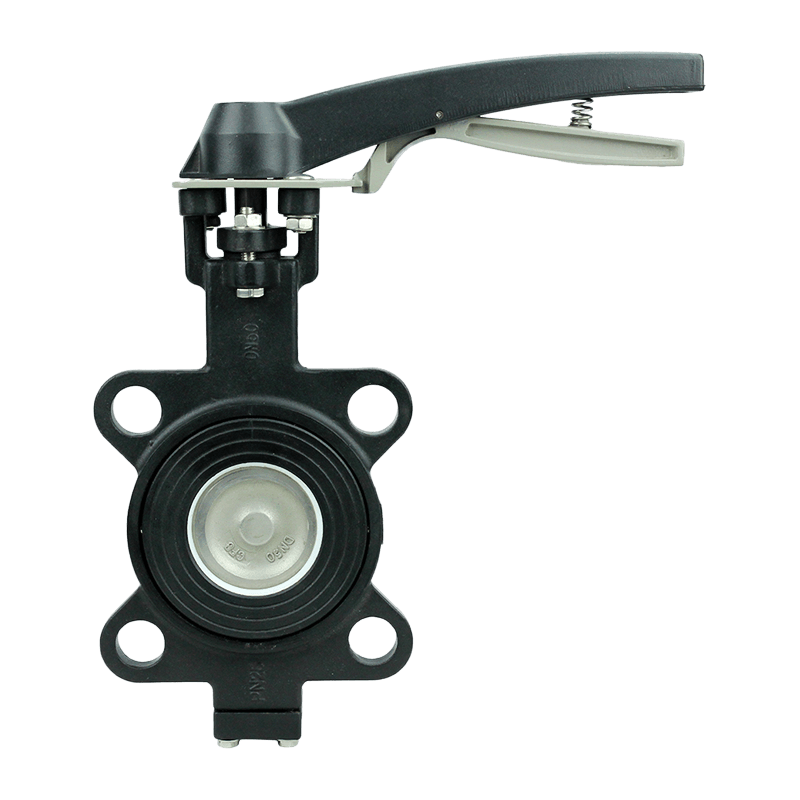

Manual Butterfly Valves Manufacturers

VATTTEN manual butterfly valves come in three different structures: centerline, double eccentric, and triple eccentric butterfly valves.

For the water treatment industry, we typically choose the centerline structure, which helps reduce costs effectively.

For the gas purification industry, we recommend using the double eccentric butterfly valve. Its design ensures a service life of up to 700,000 cycles, preventing valve leakage.

The triple eccentric butterfly valve is capable of withstanding pressures up to 64 kg, making it ideal for applications involving high temperatures, high pressures, and solid materials.

Additionally, VATTTEN offers sanitary clamp butterfly valves, which are highly popular in the food-grade powder industry and have a strong market presence.

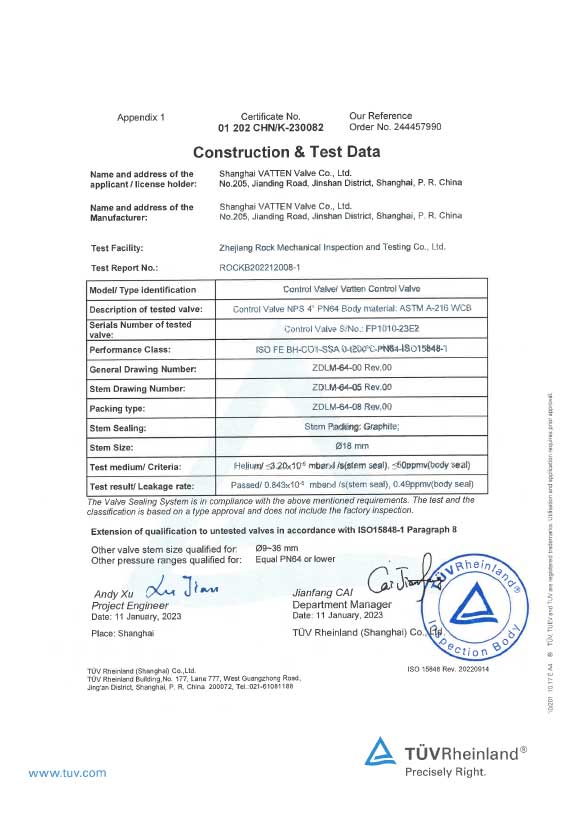

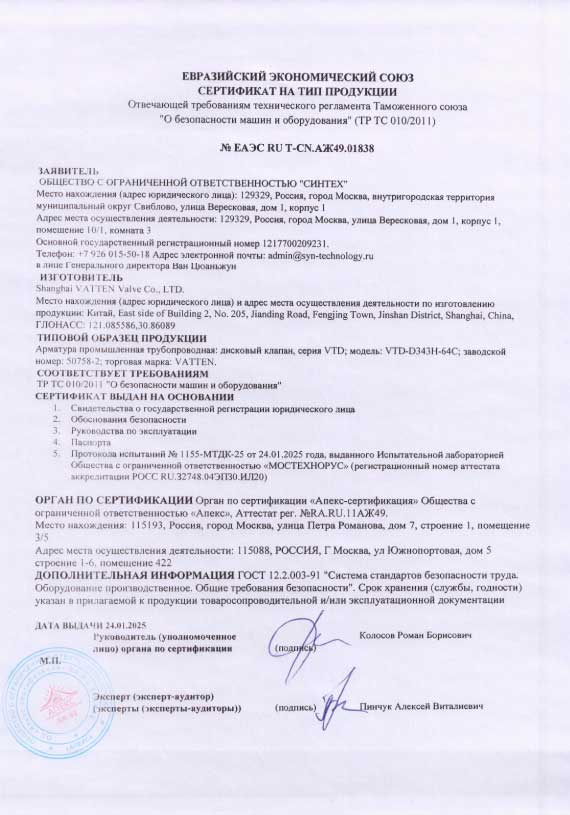

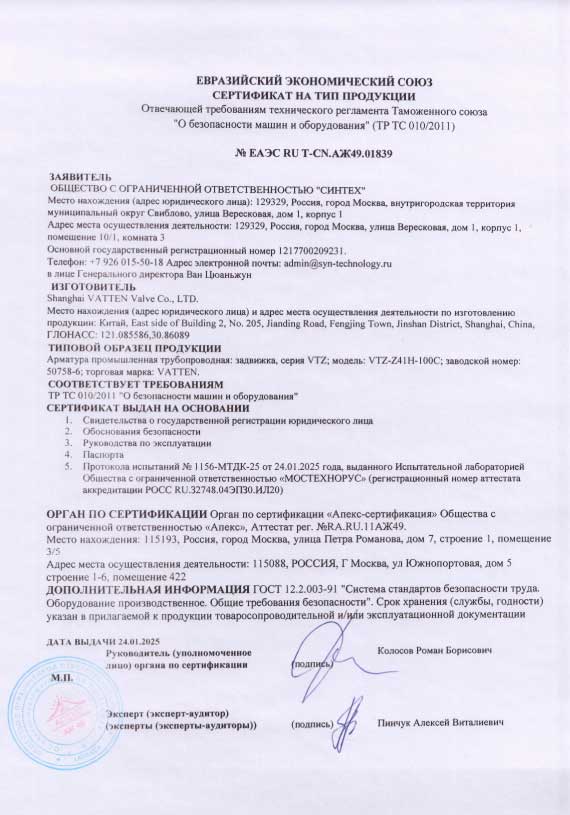

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

As Manual Butterfly Valves Manufacturers and Manual Butterfly Valves Company, the Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. Provide Custom Manual Butterfly Valves. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

-

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow controlled release of bulk solids, slurries, or liquids by gravity. They are a critical comp...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatically using an electric actuator that adjusts valve position based on control signals. They...

READ MORE -

Key Conclusion: Why Check Valves Are Essential in Fluid Systems Check valves are installed to allow fluid to flow in only one direction and automatically prevent reverse flow without manual intervention. Their...

READ MORE

Manual Control Mechanisms in Butterfly Valves

Manual butterfly valves rely on human operation for opening and closing the valve, which provides precise control over fluid flow without requiring electrical or pneumatic actuators. The hand lever or gearbox mechanism allows operators to regulate flow incrementally, making these valves suitable for applications requiring frequent adjustments or low-pressure systems.

Lever vs Gear Operation

Manual butterfly valves can be operated using a lever or a gear mechanism. Lever-operated valves offer quick on/off control and are ideal for smaller valves or low-torque applications. Gear-operated valves, on the other hand, are suitable for larger diameters and high-pressure systems, providing better torque multiplication and precise modulation.

- Lever Operation: Fast operation, simple design, limited to small diameters.

- Gear Operation: Slow but precise, supports large valves, reduces operator effort.

Torque Requirements and Handling

Understanding the torque required to operate a manual butterfly valve is critical for safety and efficiency. Torque depends on valve size, media type, pressure, and temperature. Over-torquing can damage the seat or disc, while under-torquing may prevent full closure. Operators often use torque tables to select appropriate gear ratios or extensions to hand levers.

Maintenance Tips for Manual Operation

Routine maintenance ensures smooth manual operation and prolongs valve life. Key practices include:

- Lubricate the stem and bearings to minimize friction.

- Inspect the disc and seat for wear, especially in throttling applications.

- Check the lever or gearbox mechanism for looseness or corrosion.

- Tighten mounting bolts periodically to maintain alignment.

Safety Considerations in Manual Operation

Manual operation exposes the operator directly to physical effort and potential system pressure. Safety measures include:

- Ensure the system is depressurized before operating the valve in high-pressure lines.

- Use appropriate personal protective equipment, such as gloves and eye protection.

- Consider installing locking devices to prevent accidental opening or closing.

- Train operators in torque handling and valve positioning to avoid strain or injury.

Comparison Table: Automated vs Manual Butterfly Valves

| Feature | Manual Valve | Automated Valve |

| Operation Method | Lever or gearbox | Electric, pneumatic, or hydraulic actuator |

| Control Precision | Moderate, dependent on operator skill | High, automated feedback possible |

| Installation Cost | Lower | Higher |

| Maintenance | Simple, mechanical checks | Requires actuator servicing |

| Suitable Application | Low to medium pressure, occasional operation | High-pressure, frequent operation, remote control |

English

English Deutsch

Deutsch Indonesia

Indonesia