Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the control valve cannot stably maintain an appropriate position to sustain the predetermined proc...

READ MORE

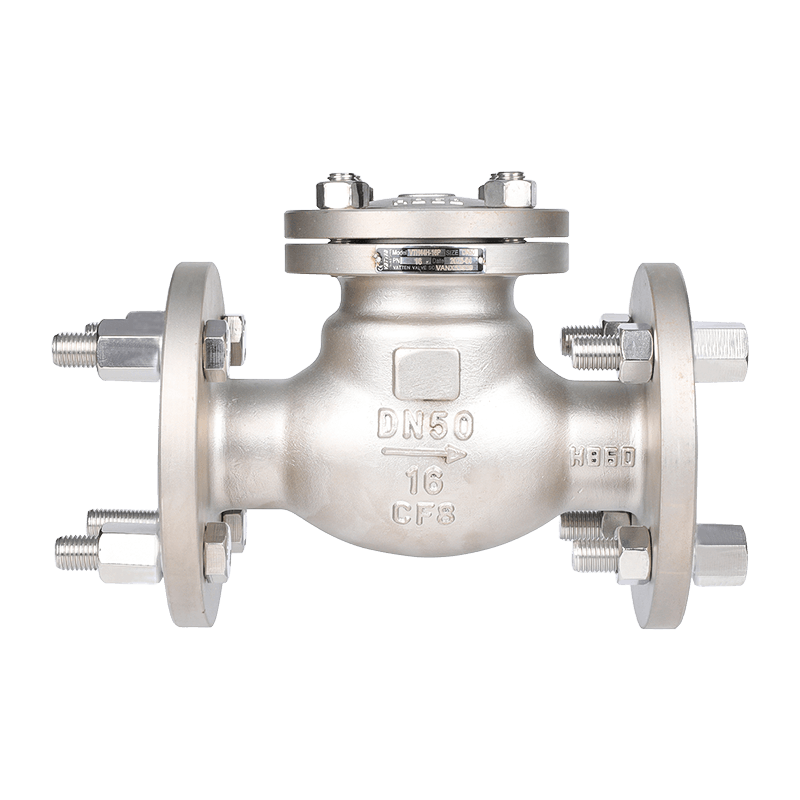

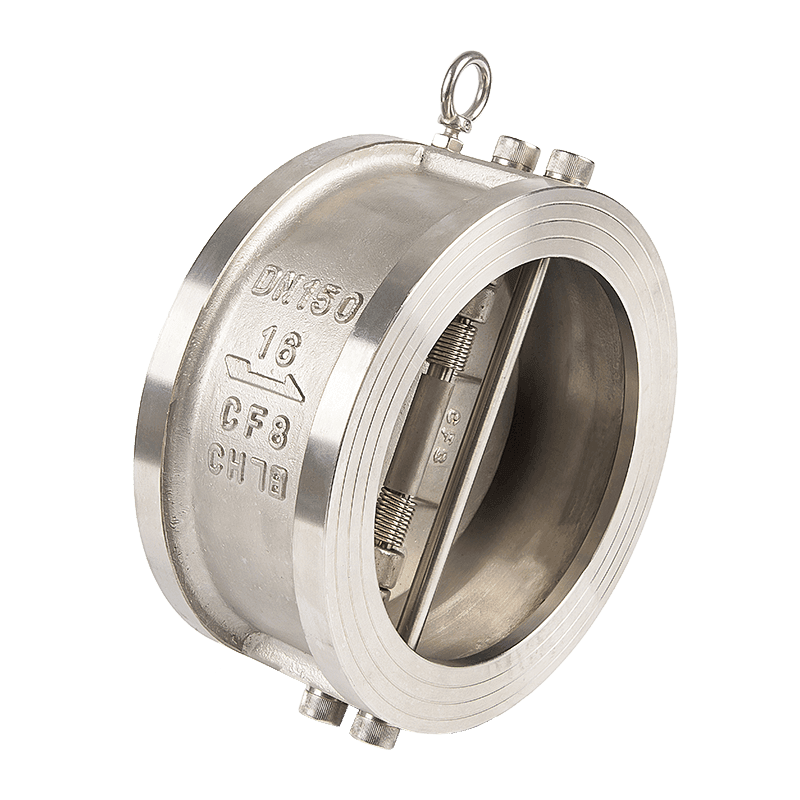

Swing Check Valves Manufacturers

Our swing check valve operates by utilizing the interaction between the valve disc and the pressure of the medium to achieve automatic opening and closing functions. When the medium flows, the valve disc is pushed open by the pressure difference; once the flow stops or reverses, the valve disc immediately closes under the pressure of the medium, preventing backflow.

This design allows the swing check valve to be widely applicable across various industries. Depending on the working conditions, the valve body can be made from different materials. Common materials such as stainless steel, carbon steel, and cast iron ensure the valve operates stably under harsh conditions.

Furthermore, the swing check valve features a simple structure and easy maintenance, making it a popular choice in many industrial sectors. It plays a crucial role, especially in industries such as water treatment, oil, and chemical processing.

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

As Swing Check Valves Manufacturers and Swing Check Valves Company, the Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. Provide Custom Swing Check Valves. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

-

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow controlled release of bulk solids, slurries, or liquids by gravity. They are a critical comp...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatically using an electric actuator that adjusts valve position based on control signals. They...

READ MORE -

Key Conclusion: Why Check Valves Are Essential in Fluid Systems Check valves are installed to allow fluid to flow in only one direction and automatically prevent reverse flow without manual intervention. Their...

READ MORE

Swing Check Valves: The Core Technology for Unidirectional Flow in Pipelines

The Swing Check Valve is a fundamentally important automatic valve. Its primary function is to ensure that fluid media in a pipeline system flows only in one predetermined direction, automatically and effectively preventing any form of backflow or reverse flow. This valve operates entirely using the fluid’s inherent pressure, requiring no external power or manual intervention, hence its designation as a “one-way valve.”

I. Precise Operating Principle and Mechanism

The operational mechanism of the Swing Check Valve is based on the principles of fluid thrust and gravity.

-

Open State (Forward Flow): When the medium flows in the normal direction, its kinetic energy and pressure create a thrust acting on the disc. Once this thrust overcomes the disc’s weight and the friction of the hinge, the disc swings open around the hinge pin in the direction of the flow. In its fully open state, the flow path is nearly straight-through, which provides extremely low resistance to the fluid.

-

Closed State (Reverse Flow Tendency): When the pump stops, flow velocity decreases, or a reverse flow attempt occurs, the disc loses the forward thrust. The disc then rapidly and automatically swings back onto the seat due to the combined force of its gravity and the reverse pressure of the medium. The greater the reverse pressure, the tighter the disc presses against the seat, leading to more reliable sealing performance.

Rooted in the German tradition of precision manufacturing, Vatten Valve Group maintains its focus on automatic control valves while strictly adhering to international quality standards. This commitment to precision is integral to the design and manufacturing of critical components like the hinge pin and seat in our check valves, ensuring longevity and reliable operation.

II. Core Structure and Component Analysis

While the structure of a Swing Check Valve appears straightforward, its reliability depends on the synchronized operation of several key components:

- Body: It serves as the shell and framework, withstanding pipeline pressure and connecting to the system. The body features a straight-through flow design to minimize fluid resistance.

- Disc: The core component that executes the opening and closing function. It’s connected by a hinge arm to the valve’s hinge pin, allowing it to swing. Disc materials must be compatible with the conveyed medium.

- Seat: The sealing surface inside the body that contacts the disc. The seat is often inlaid with wear-resistant or resilient materials to ensure a long-term, reliable seal.

- Hinge Pin: The pivot point for the disc’s movement. The pin’s strength and precise positioning are critical for valve performance and durability.

- Bonnet: It seals the internal space, providing an access port for maintenance or inspection of the internal components.

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Our expertise in automatic control ensures that even our passive components, like swing check valves, are engineered to the highest standards of reliability and material integrity.

III. Technical Advantages and Fluid Characteristics

The widespread adoption of the Swing Check Valve is driven by its unique product advantages:

- Ultra-Low Flow Resistance and Pressure Drop: When the disc is fully open, the flow path is nearly straight. This results in an extremely low flow resistance coefficient, which is crucial for high-flow, long-distance piping systems, as it effectively reduces pumping energy consumption.

- Broad Applicability: It can handle diverse media, including clean water, wastewater, steam, oil, gases, and fluids containing suspended solids.

- Reliable Self-Sealing: The reverse pressure of the medium increases the force pushing the disc onto the seat, thereby enhancing the sealing tightness—a characteristic known as automatic sealing reinforcement.

IV. Installation Considerations and Water Hammer Mitigation

In engineering applications, it’s essential to consider the installation requirements and potential technical challenges associated with Swing Check Valves:

- Installation Orientation: Traditional Swing Check Valves primarily rely on gravity to assist closure, so they are typically required to be installed in horizontal pipelines. When vertical installation is unavoidable, a special design featuring spring-assisted closure must be selected.

- Water Hammer Risk: This is a major concern. When a pump suddenly stops, the flow quickly reverses, causing the disc to slam rapidly and violently against the seat. This impact generates a powerful, instantaneous pressure wave known as “water hammer.”

- Mitigation Techniques: To address water hammer risk, specialized designs are often used for high-velocity or large-diameter pipelines:

- External Lever and Counterweight: By adjusting the weight and lever length, the disc’s closing speed and force can be precisely controlled and cushioned.

- Tilting Disc Design: This design shortens the disc’s stroke, enabling it to close sooner and more smoothly before the fluid completely reverses.

Leveraging our exceptional technological expertise, Vatten Valve Group delivers innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges, particularly the challenges associated with high-pressure water hammer in critical infrastructure.

English

English Deutsch

Deutsch Indonesia

Indonesia