Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the control valve cannot stably maintain an appropriate position to sustain the predetermined proc...

READ MORE

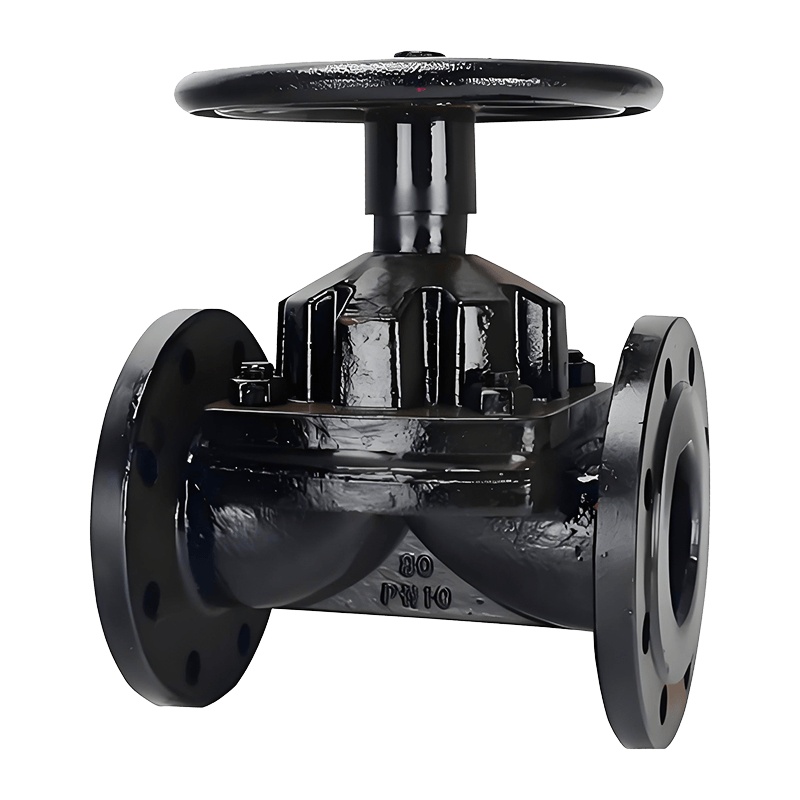

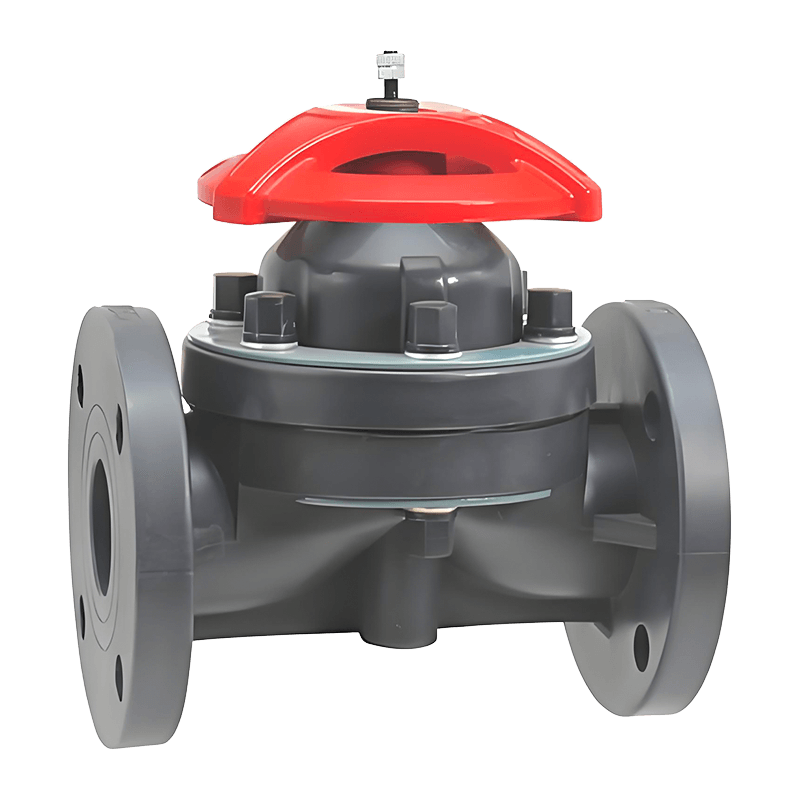

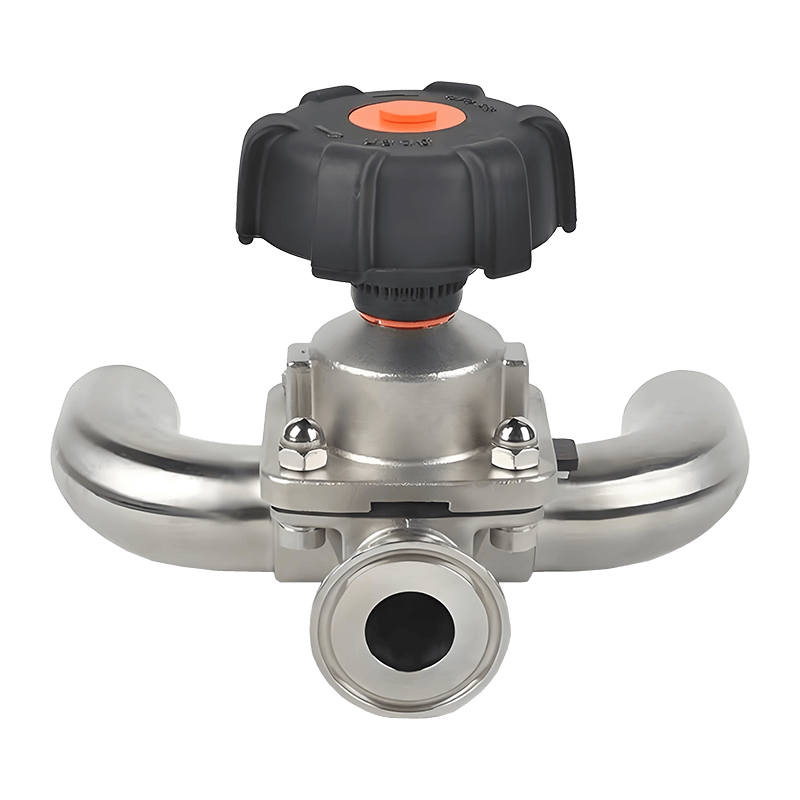

Manual Diaphragm Valves Manufacturers

The manual diaphragm valves produced by VATTEN are made from high-quality materials such as UPVC, CPVC, PPH, 304, 316, and 316L. We offer a variety of diaphragm valve models tailored to different pipeline configurations. The choice of materials ensures excellent corrosion resistance, high-temperature tolerance, and pressure endurance, making them suitable for diverse industrial applications.

The key component of the diaphragm valve, the diaphragm, is made from a composite material of EPDM and PTFE. This composite material offers superior chemical stability and resistance to aging compared to traditional materials, significantly extending the valve’s service life. With rigorous testing, diaphragm valves using this material can last 2 to 3 times longer, reducing maintenance frequency and ensuring efficient operation.

VATTEN’s manual diaphragm valves are designed for simplicity and efficiency, widely used in pipeline systems across industries such as chemicals, food, and pharmaceuticals. Through precise craftsmanship and strict quality control, VATTEN’s manual diaphragm valves not only deliver outstanding performance but are also reliable and durable, meeting the diverse needs of users in complex environments

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

As Manual Diaphragm Valves Manufacturers and Manual Diaphragm Valves Company, the Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. Provide Custom Manual Diaphragm Valves. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

-

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow controlled release of bulk solids, slurries, or liquids by gravity. They are a critical comp...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatically using an electric actuator that adjusts valve position based on control signals. They...

READ MORE -

Key Conclusion: Why Check Valves Are Essential in Fluid Systems Check valves are installed to allow fluid to flow in only one direction and automatically prevent reverse flow without manual intervention. Their...

READ MORE

Ergonomics and handwheel torque for manual operation

When manual diaphragm valves are operated by hand for multiple cycles per shift, the physical design of the actuator and the specified handwheel torque directly affect operator fatigue and repeatability. Specify handwheels sized to allow two-handed operation when required, and verify the valve's published operating torque at the working differential pressure before installation. In retrofit scenarios, measure the real-world torque using a torque wrench at ambient temperature and full line pressure—this prevents undersized manual actuators and reduces the risk of slow, inconsistent seating that leads to leaks.

Practical torque checks on-site

- Perform a torque sweep: record torque at 25%, 50%, 75% and 100% open to find non-linear resistance peaks that indicate debris or misalignment.

- Compare measured torque to manufacturer limits; a sustained increase above 20–30% usually signals seat wear or diaphragm hardening.

- Document torque values after maintenance and before commissioning to establish a baseline for predictive maintenance.

Manual operation techniques for precise flow control

Manual diaphragm valves can be used for throttling but their flow characteristic and seat geometry affect controllability. For precise regulation in a manual work scene, operate the valve with small incremental turns near the mid-travel where the relationship between stem position and flow is most linear, and use a simple mechanical position stop or index marks on the handwheel to repeat setpoints reliably between operators.

Tips to improve manual repeatability

- Mark commonly used handwheel positions with durable paint or a stamped index to remove guesswork when multiple operators share duties.

- Install a calibrated position indicator where possible; even a simple mechanical pointer gives better reproducibility than feel alone.

- For slow processes, adopt a “small-step then wait” routine: adjust 1/8–1/4 turn, wait for process stabilization, then re-check readings before further adjustment.

Routine maintenance checklist for field technicians

A concise, task-oriented maintenance checklist reduces downtime and avoids unnecessary full disassembly. Focus on external checks, quick functional tests, and periodic internal inspections on a defined schedule tied to cycles and operating conditions rather than calendar time alone.

- Daily/shift: visual check for visible leaks, handwheel free movement, and intact position markings.

- Weekly: operate valve full open/close to detect sticking; note any unusual torque spikes.

- Quarterly (or after X cycles): remove actuator cover, inspect diaphragm for hardening, cracks, or particulate embedding; replace if elasticity is compromised.

- After any abrasive service: shorten inspection interval and check bonnet seals, seat faces, and internal guides for accelerated wear.

Step-by-step diaphragm replacement for minimal downtime

Field technicians can replace diaphragms quickly when they follow a standardized sequence that isolates pressure, drains the cavity, and preserves alignment. Preparation and the right tooling cut replacement time and reduce the chance of pinch folds or mis-seating that cause immediate leaks.

Recommended replacement procedure

- Lockout and tagout the supply lines; relieve and verify zero pressure in the valve body and actuator chamber.

- Back off actuator preload to remove diaphragm tension, then unbolt the bonnet using the star pattern to avoid distortion.

- Clean sealing surfaces with lint-free cloth and a mild solvent; inspect the seat and upper guide for nicks or embedded particles.

- Fit new diaphragm centered over the seat; use alignment pins or temporary markers if the design provides them, then hand-tighten bonnet bolts in a criss-cross pattern to manufacturer torque specs.

- Cycle the valve slowly under test pressure to confirm sealing, then document part number, lot, and date for traceability.

Troubleshooting common failures in manual work scenes

Problems encountered during manual operation are typically either mechanical (stiffness, broken handwheel), sealing (leak-at-seat, bonnet leak), or process-related (cavitation, particulate abrasion). Use a structured diagnostic sequence—visual, mechanical, pressure test, internal inspection—to isolate root cause instead of repeatedly replacing diaphragms or seats without addressing upstream contributors.

Quick diagnostic flow

- If torque increases slowly over cycles: inspect for particulate build-up or corrosion on the stem and guides.

- If leakage occurs immediately after tightening: check for folded diaphragm edges, improper seating, or incorrect bolt torque sequence.

- If intermittent leakage under certain flows: investigate cavitation, vapor formation, or pulsation causing diaphragm fatigue.

Selecting materials and linings for manual handling environments

Material selection should balance durability, tactile safety for operators, and the process medium. In manually operated valves the external surfaces that operators touch—handwheels, stems, and bonnet covers—should resist corrosion and provide grip while internal diaphragms and seats must match chemical compatibility and abrasion resistance.

| Diaphragm / Seat Material | Best-fit Applications | Manual-scene notes |

| EPDM | Hot water, mild acids, alkalis | Good elasticity; inspect for swelling when exposed to oils. |

| PTFE-lined | Strong acids, solvents | Low friction for manual operation; higher cost but minimal sticking. |

| Nitrile (Buna-N) | Oils, fuels | Good abrasion resistance; check hardness to maintain seal under manual torque. |

Safety, lockout/tagout and pressure testing best practices

Because manual scenes often involve frequent operator access, standardize lockout/tagout steps specifically for manual diaphragm valves: isolation, field pressure verification with an independent gauge, slow venting of trapped cavities, and the use of rated personal protective equipment. For pressure testing after maintenance, always use hydrostatic or pneumatic tests compatible with the valve design and record test pressure, duration, and the observed leakage rate.

Recommended on-site safety sequence

- Isolate upstream and downstream sources and apply locks; verify zero energy with an independent pressure gauge positioned at the valve inlet.

- Wear face shield and chemical-resistant gloves when loosening bonnets or working on valves that handled corrosives or hot media.

- After maintenance, perform a low-pressure leak test before returning to full service; document results and any nonconformances.

English

English Deutsch

Deutsch Indonesia

Indonesia