Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the control valve cannot stably maintain an appropriate position to sustain the predetermined proc...

READ MORE

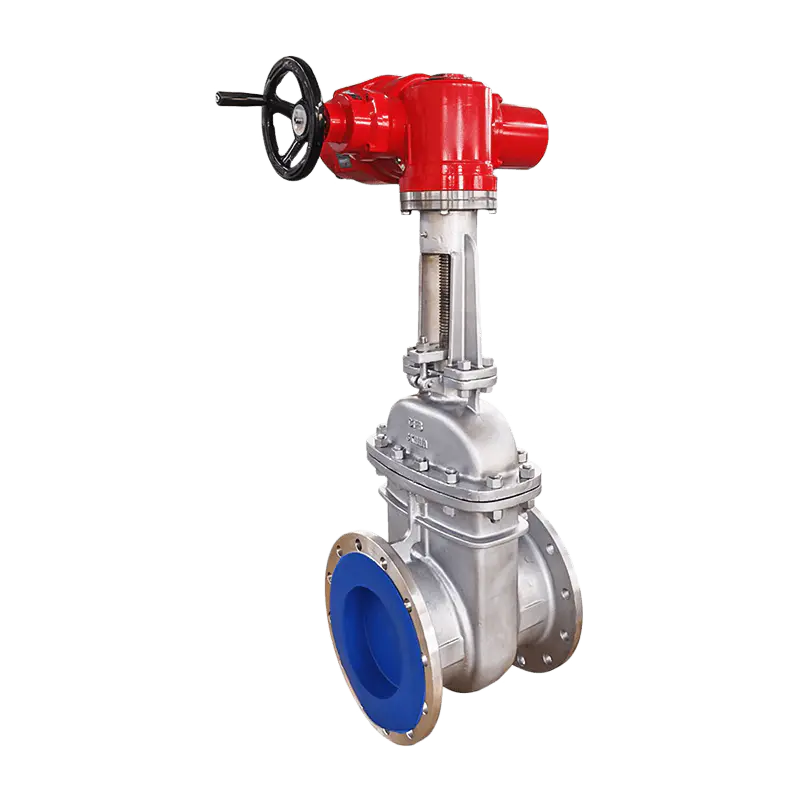

Electric Gate Valves Manufacturers

The VATTEN electric gate valve is one of the most widely used products in our range, particularly in the municipal sector, known for its excellent opening and closing functions. This electric gate valve employs advanced electric control technology to achieve precise operation, ensuring smooth fluid flow and the efficient functioning of the system.

In water treatment plants, the performance of the VATTEN electric gate valve stands out. It effectively regulates water flow while maintaining a strong seal, reducing maintenance frequency and significantly enhancing the stability and service life of the equipment. Moreover, its design takes into account corrosion resistance and durability, making it suitable for complex water environments.

In addition, the VATTEN electric gate valve is extensively used in river management and other engineering projects. In these projects, the valve's automatic control function greatly improves the overall efficiency and safety of the operations, minimizing risks associated with manual intervention.

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

As Electric Gate Valves Manufacturers and Electric Gate Valves Company, the Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. Provide Custom Electric Gate Valves. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

-

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow controlled release of bulk solids, slurries, or liquids by gravity. They are a critical comp...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatically using an electric actuator that adjusts valve position based on control signals. They...

READ MORE -

Key Conclusion: Why Check Valves Are Essential in Fluid Systems Check valves are installed to allow fluid to flow in only one direction and automatically prevent reverse flow without manual intervention. Their...

READ MORE

What Are the Common Maintenance Practices for Electric Gate Valves?

Electric gate valves are critical components in various industries, providing automated control for the flow of fluids and gases in systems that require precise and efficient operation. While electric gate valves are designed for durability and long-term use, proper maintenance is essential to ensure their optimal performance and longevity. Regular maintenance practices not only help avoid unexpected failures but also enhance the safety and efficiency of the entire system. In this article, we will explore the common maintenance practices for electric gate valves, focusing on the tasks that help extend their lifespan and maintain peak performance.

Understanding Electric Gate Valves

Electric gate valves use an electric actuator to control the opening and closing of the valve. These valves are often used in automated control systems where remote operation is required. The actuator, typically powered by electricity, is responsible for moving the gate (or wedge) in and out of the valve body, allowing or blocking the flow of fluids or gases. Electric gate valves are commonly found in industrial applications such as water treatment, oil and gas, chemical processing, and HVAC systems.

Despite their automation and ease of operation, electric gate valves are still mechanical devices that require regular maintenance to ensure long-term reliability. Neglecting routine maintenance can lead to premature wear, reduced performance, or even valve failure, which can cause system downtime or unsafe conditions.

Key Components of Electric Gate Valves

Before diving into the maintenance practices, it's important to understand the key components of an electric gate valve. These components include:

- Electric Actuator: The component that powers the valve's opening and closing mechanism. It is typically controlled by a motor and can be either a stepper motor, DC motor, or AC motor, depending on the application.

- Gate or Wedge: The part of the valve that physically obstructs or allows the flow of fluid or gas. The gate moves vertically within the valve body to control flow.

- Valve Stem: The part that connects the electric actuator to the gate. The stem moves the gate up and down when the actuator is engaged.

- Seals and Packing: These components help ensure that the valve is leak-proof when in the closed position, preventing fluid or gas from escaping the system.

- Limit Switches: These devices signal when the valve is fully open or fully closed, providing feedback to the control system to prevent over-travel and damage to the actuator.

Common Maintenance Practices for Electric Gate Valves

1. Regular Inspection of Actuators

The actuator is the heart of an electric gate valve, as it is responsible for controlling the valve's operation. Regular inspection of the actuator is crucial to ensure smooth operation and prevent premature failure. During inspections, check the following:

- Motor Function: Ensure that the motor is functioning properly by observing if the actuator moves the gate smoothly and without hesitation.

- Electrical Connections: Inspect the wiring and connections for signs of wear, corrosion, or loose connections, which can cause power interruptions or malfunctioning of the actuator.

- Lubrication: Check if the actuator requires lubrication to reduce friction and ensure that moving parts do not wear out prematurely.

2. Seal and Packing Inspection

The seals and packing in an electric gate valve prevent fluid or gas leaks when the valve is closed. Over time, these components can degrade due to constant pressure and flow, leading to leaks or inefficient sealing. Inspect the seals and packing regularly for signs of wear, cracking, or deformation. If any damage is found, replace the seals to maintain the valve’s leak-proof integrity. Common checks include:

- Look for signs of leakage around the valve body.

- Inspect the packing gland for tightness and adjust if necessary.

- Check for excessive stem movement, which could indicate that the packing is worn or damaged.

3. Cleaning and Debris Removal

Electric gate valves are exposed to various conditions that can introduce dirt, debris, and contaminants into the system. These particles can clog the valve’s components, interfere with the actuator’s movement, and cause the valve to malfunction. Regular cleaning and debris removal are essential maintenance practices:

- Clean the valve body and actuator to prevent buildup of contaminants that could impede smooth operation.

- Check for any foreign objects lodged in the valve seat or stem, and remove them carefully.

- If the valve is used in harsh environments (e.g., chemicals or abrasive materials), use appropriate cleaning solutions to ensure safe and effective cleaning.

4. Testing the Limit Switches

Limit switches are crucial in preventing the valve from over-traveling, which could damage the actuator or the valve itself. Over time, limit switches can become misaligned or malfunction. Testing the limit switches regularly ensures that the valve stops at the correct open and closed positions:

- Test the limit switches by manually moving the valve and checking that the switches are engaging when the valve reaches its fully open or closed positions.

- Adjust the limit switches if necessary to ensure proper valve positioning.

- Inspect the electrical contacts of the limit switches for wear or corrosion and replace them if needed.

5. Lubrication of Moving Parts

Proper lubrication is essential to ensure that the moving components of the electric gate valve operate smoothly and efficiently. The valve stem, actuator components, and other moving parts should be lubricated periodically to reduce wear and friction. Lubrication helps prevent the accumulation of dirt and debris, which can lead to corrosion or valve failure. Be sure to:

- Use the correct type of lubricant for the specific valve components, as recommended by the manufacturer.

- Lubricate the valve stem and actuator regularly, particularly in systems with high-frequency operation.

- Inspect for excess lubrication, which can attract contaminants and cause operational problems.

6. Monitoring and System Diagnostics

In automated systems, continuous monitoring and diagnostics are essential to ensure that the electric gate valve operates correctly. Many modern control systems come equipped with diagnostic tools that can monitor the valve’s performance and alert operators to potential issues before they become critical:

- Use system diagnostics to monitor valve performance, including actuator speed, valve position, and control signals.

- Install pressure and temperature sensors to detect any abnormal conditions that could affect the valve’s operation.

- Regularly check the control system to ensure that it is providing accurate feedback from the valve’s limit switches and actuators.

Conclusion

Regular maintenance of electric gate valves is critical to ensuring that they operate efficiently and reliably. By following these maintenance practices—such as inspecting actuators, checking seals and packing, cleaning components, and testing limit switches—industries can extend the life of their electric gate valves, reduce the risk of unexpected failures, and improve system safety.

By integrating these common maintenance practices into regular service schedules, industries can keep their electric gate valves performing at optimal levels. Timely inspection and repairs, along with proper lubrication and cleaning, ensure that the valves remain durable and continue to meet the demands of automated control systems. Furthermore, adopting a predictive maintenance approach by utilizing system diagnostics and monitoring tools can help identify potential issues before they lead to expensive repairs or operational interruptions.

Ultimately, the key to maintaining electric gate valves is a comprehensive maintenance strategy that includes both preventative measures and corrective actions when necessary. With consistent upkeep, these valves will continue to provide reliable service, contribute to efficient flow control, and ensure the overall safety of the industrial systems they support.

English

English Deutsch

Deutsch Indonesia

Indonesia