Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the control valve cannot stably maintain an appropriate position to sustain the predetermined proc...

READ MORE

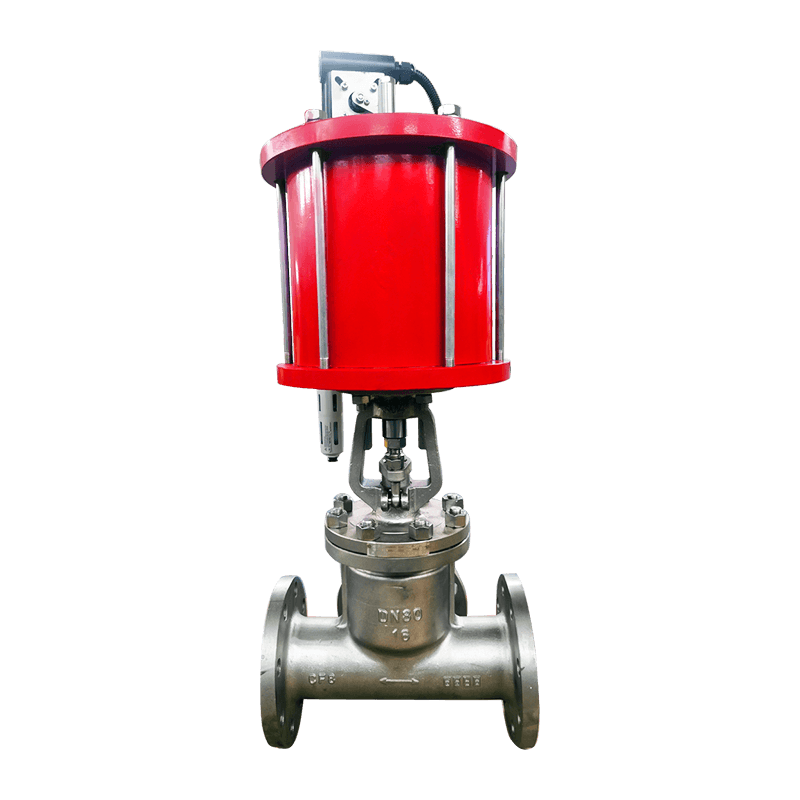

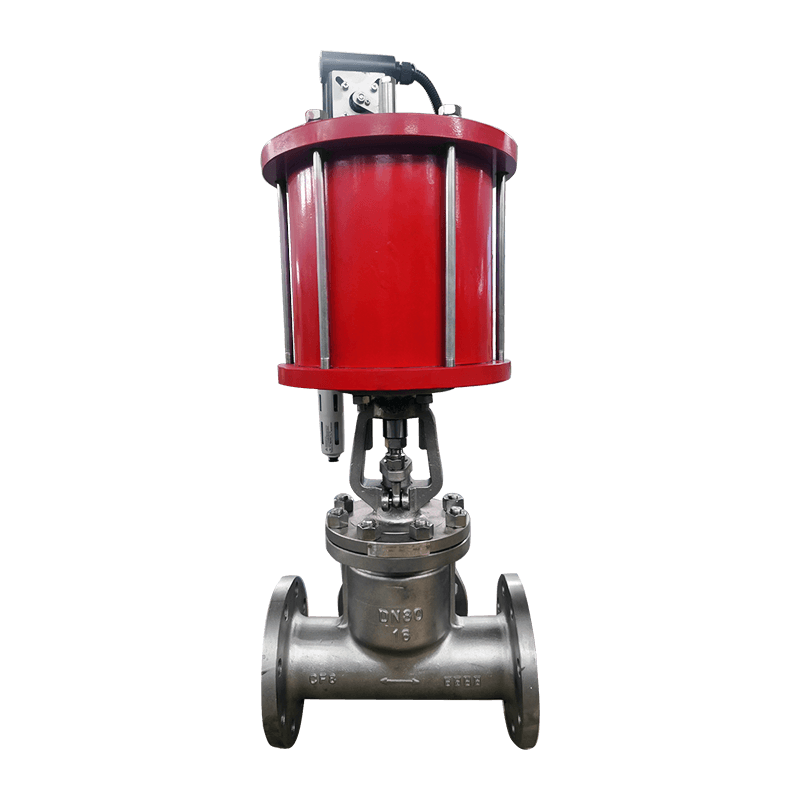

Pneumatic Shut Off Valves Manufacturers

VATTEN’s Pneumatic shut off valve is equipped with a cast steel pneumatic actuator, offering excellent resistance to high pressure and temperature. This valve effectively isolates gaseous media within the pipeline, ensuring stable operation under high-pressure and high-temperature conditions. Particularly in handling high-temperature gases, the design of the pneumatic stop valve meets stringent operational requirements, ensuring precise control of fluid flow. This makes it an ideal choice in many industrial sectors, especially in energy, petrochemical, and chemical industries.

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

As Pneumatic Shut Off Valves Manufacturers and Pneumatic Shut Off Valves Company, the Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. Provide Custom Pneumatic Shut Off Valves. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

-

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow controlled release of bulk solids, slurries, or liquids by gravity. They are a critical comp...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatically using an electric actuator that adjusts valve position based on control signals. They...

READ MORE -

Key Conclusion: Why Check Valves Are Essential in Fluid Systems Check valves are installed to allow fluid to flow in only one direction and automatically prevent reverse flow without manual intervention. Their...

READ MORE

Air Supply Quality and Its Impact on Pneumatic Shut Off Valves Performance

The performance and reliability of pneumatic shut off valves depend heavily on the quality of the compressed air supply. Moisture, oil, and particulate contamination can cause internal corrosion, clogging, or premature seal degradation. To maintain consistent performance, air filtration systems should include moisture separators, oil mist filters, and fine particulate filters. Regular inspection and replacement of these components ensure that the pneumatic actuators receive clean and dry air, reducing downtime and extending service life.

Response Time Optimization in Pneumatic Shut Off Systems

In automation systems, the response time of pneumatic shut off valves are critical for process safety and control precision. Factors influencing response time include air pressure, actuator volume, solenoid valve selection, and line length. Shorter air lines and appropriately sized actuators help reduce delay, while using quick exhaust valves can further accelerate operation. Regular calibration and monitoring of signal-to-action time can help identify air leaks or control signal inconsistencies that may affect valve responsiveness.

Comparison Between Single-Acting and Double-Acting Pneumatic Shut Off Valves

Pneumatic shut off valves are available in single-acting and double-acting configurations, each suitable for specific operational needs. The following table summarizes their main differences and ideal application scenarios:

| Type | Operating Principle | Advantages | Typical Application |

| Single-Acting | Uses air pressure to open or close; spring return for opposite action | Failsafe design; simple air control | Emergency shutdown or safety-critical systems |

| Double-Acting | Air pressure applied alternately to open and close positions | Balanced movement; faster cycle speed | Process automation requiring precise positioning |

Integration of Pneumatic Shut Off Valves in Safety Interlock Systems

In modern industrial setups, pneumatic shut off valves often form part of safety interlock systems designed to automatically isolate process sections during fault conditions. By connecting the valve to sensors or emergency stop circuits, the system ensures immediate shutoff of compressed air, gases, or liquids to prevent accidents. It is essential that these valves feature a manual override function, allowing operators to manually control flow during maintenance or in the event of control system failure.

Common Failure Modes and Preventive Measures for Pneumatic Shut Off Valves

Even though pneumatic shut off valves are known for their reliability, they can experience failure due to mechanical fatigue, contamination, or control signal malfunction. Preventive maintenance is key to ensuring long-term stability and safety. The following practices are recommended:

- Inspect actuator seals and diaphragms regularly for wear or cracks.

- Drain condensate from air tanks and filters to prevent moisture accumulation.

- Verify solenoid valve operation and electrical connections for stability.

- Lubricate moving components with compatible pneumatic grease when required.

Noise Reduction Strategies in Pneumatic Shut Off Valve Systems

High-speed air exhaust during valve actuation can generate significant noise, especially in open systems. Installing pneumatic silencers on exhaust ports can reduce noise levels without impairing system performance. Selecting flow control valves that limit exhaust velocity also helps achieve quieter operation. Additionally, placing the valve in enclosed or acoustically treated areas contributes to a safer and more comfortable working environment for operators.

Energy Efficiency Considerations in Pneumatic Shut Off Valves

Energy consumption in pneumatic systems is often overlooked, yet compressed air generation is one of the most energy-intensive processes in industry. Pneumatic shut off valves that minimize leakage and pressure loss can significantly reduce operating costs. Smart monitoring systems that detect and report minor leaks allow maintenance teams to take corrective actions early. Optimizing actuator sizing and using pressure regulators tuned to the exact requirements of the system can further improve energy efficiency.

Adapting Pneumatic Shut Off Valves for Extreme Environments

Certain industries, such as offshore drilling or cryogenic processing, require pneumatic shut off valves that can perform under extreme temperature or pressure variations. For low-temperature environments, special elastomers and lubricants that remain flexible at subzero conditions are essential. In high-temperature or corrosive atmospheres, stainless steel or nickel-plated materials provide enhanced durability. Ensuring proper enclosure ratings for the actuator and solenoid components is also critical to prevent moisture ingress and electrical failure.

Smart Pneumatic Shut Off Valves and Digital Control Integration

The latest trend in automation involves integrating pneumatic shut off valves with digital communication networks such as IO-Link or fieldbus systems. These smart valves transmit real-time operational data including position feedback, cycle counts, and diagnostic alerts. The information allows predictive maintenance, reducing unplanned downtime and improving process control. As industrial IoT continues to expand, these intelligent pneumatic valves are becoming a core component of connected manufacturing environments.

English

English Deutsch

Deutsch Indonesia

Indonesia