Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the control valve cannot stably maintain an appropriate position to sustain the predetermined proc...

READ MORE

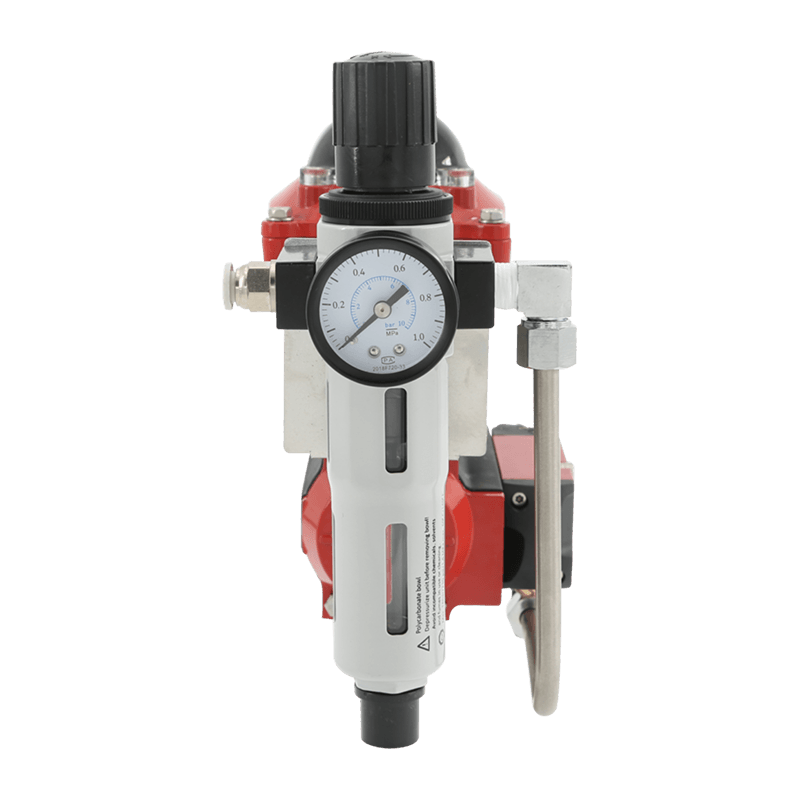

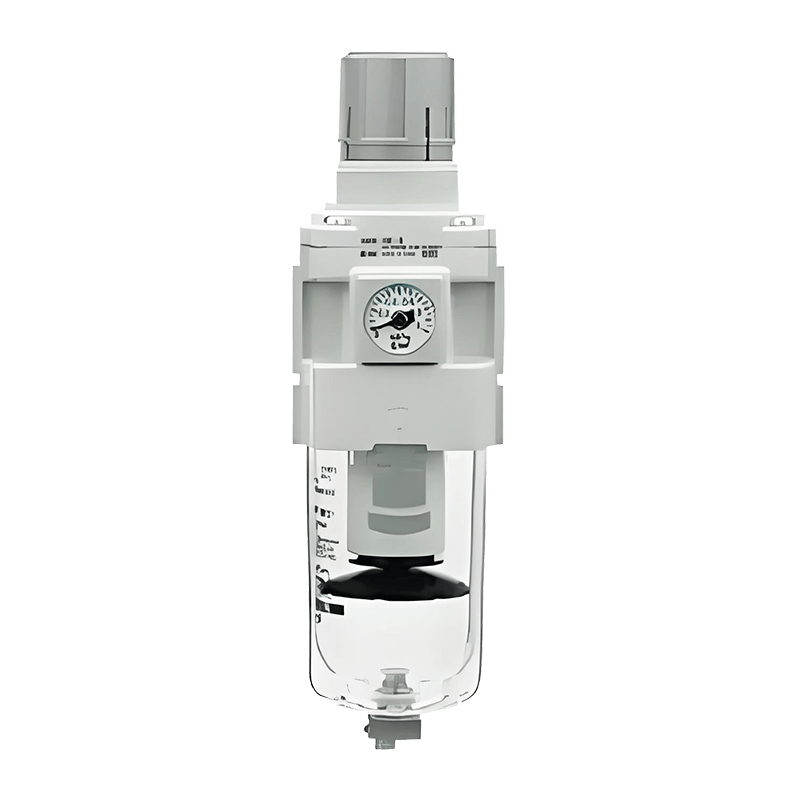

Filter Pressure Reducing Valves Manufacturers

The filter pressure reducing valve effectively removes impurities and moisture from the air supply, ensuring that clean gas reaches your actuator and prolonging its lifespan. Its filtration function guarantees that clean, impurity-free gas enters the actuator, preventing damage caused by contaminants.

In addition, the filter pressure reducing valve plays a dual protective role in the system. On one hand, it ensures a stable gas flow, while on the other hand, its pressure reduction function keeps the actuator operating within a safe pressure range, significantly extending the actuator's service life. Over time, this reduces the frequency of maintenance, lowers failure rates, and enhances the overall reliability of the equipment.

By installing a filter pressure reducing valve, the efficiency of the gas system is greatly improved, and the risk of damage caused by moisture and impurities is minimized, ensuring the high performance of the system. Its efficient filtration and pressure reduction functions ensure the safety and stability of the entire pneumatic system, making it an essential component for equipment protection.

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

As Filter Pressure Reducing Valves Manufacturers and Filter Pressure Reducing Valves Company, the Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. Provide Custom Filter Pressure Reducing Valves. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

-

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow controlled release of bulk solids, slurries, or liquids by gravity. They are a critical comp...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatically using an electric actuator that adjusts valve position based on control signals. They...

READ MORE -

Key Conclusion: Why Check Valves Are Essential in Fluid Systems Check valves are installed to allow fluid to flow in only one direction and automatically prevent reverse flow without manual intervention. Their...

READ MORE

Optimizing Actuator Protection Through Filtered Air Supply

The efficiency of pneumatic actuators directly depends on the quality and pressure stability of the air supply. Vatten Valve Group’s filter pressure reducing valves remove microscopic particles, oil, and moisture before the air reaches the actuator. By preventing contaminants from entering delicate actuator mechanisms, these valves reduce wear on internal seals, pistons, and bearings, significantly extending service life and reducing the frequency of unscheduled maintenance.

Pressure Reduction for Safe and Stable Operation

Actuators are often sensitive to pressure spikes or fluctuations that can cause mechanical stress or erratic movement. The pressure reduction function of Vatten filter valves maintains a stable downstream pressure, ensuring that the actuator operates within safe limits. This prevents premature fatigue of actuator components and minimizes the risk of system downtime, particularly in high-frequency or critical applications where reliability is paramount.

Practical considerations for pressure adjustment

- Select the downstream pressure to match actuator specifications, avoiding overpressure conditions that could deform seals.

- Periodically check valve settings for drift due to vibration or temperature changes.

- Use gauges or pressure sensors to verify stable output, particularly in complex networked pneumatic systems.

Moisture and Contaminant Removal for Critical Systems

Moisture in compressed air can lead to corrosion, freezing, or microbial growth inside actuators and connected equipment. Vatten filter pressure reducing valves integrate coalescing or particulate filters that efficiently capture moisture and debris, ensuring that only clean, dry air enters the system. This filtration capability is especially crucial in industries such as chemical processing, pharmaceuticals, and food manufacturing, where contamination can compromise both equipment and product integrity.

Key filtration benefits

- Reduces corrosion in actuator cylinders and piping.

- Prevents blockage or sticking of precision valves and regulators.

- Extends interval between filter maintenance and actuator overhauls.

Enhancing System Reliability and Maintenance Efficiency

By combining pressure reduction with efficient filtration, Vatten filter valves reduce the likelihood of actuator failure due to mechanical wear or contamination. This dual function improves overall system reliability and reduces downtime. Maintenance teams benefit from predictable intervals for filter replacement and pressure verification, allowing for proactive service rather than reactive repair, which minimizes operational disruption.

Performance Metrics and Monitoring for Critical Applications

For high-demand pneumatic networks, monitoring the performance of filter pressure reducing valves is essential. Parameters such as differential pressure across the filter, outlet pressure stability, and air quality indicators can be tracked to ensure optimal operation. Integrating these valves with sensor feedback systems enables real-time alerts for filter clogging or pressure deviations, allowing maintenance personnel to take timely action before equipment is affected.

| Parameter | Recommended Monitoring Method | Action on Deviation |

| Differential pressure across filter | Pressure gauge or transmitter | Replace or clean filter element |

| Outlet pressure stability | Digital pressure sensor with logging | Adjust regulator or perform maintenance check |

| Air quality (moisture / particulates) | Inline moisture / particle sensor | Schedule drying or filter replacement |

Industrial Best Practices for Filter Pressure Reducing Valve Installation

Proper installation and orientation are critical for optimal valve performance. Position valves in accessible locations for monitoring and maintenance, and ensure that the flow direction matches the inlet and outlet markings. Incorporate isolation valves upstream and downstream to allow maintenance without shutting down the entire system. For multi-valve networks, consider parallel filtration to reduce pressure drop and maintain consistent air quality throughout the system.

- Mount valves vertically to facilitate condensate drainage.

- Use vibration dampening brackets in high-vibration environments.

- Perform periodic calibration of pressure regulators to maintain actuator safety.

English

English Deutsch

Deutsch Indonesia

Indonesia