Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the control valve cannot stably maintain an appropriate position to sustain the predetermined proc...

READ MORE

Valve Positioner Manufacturers

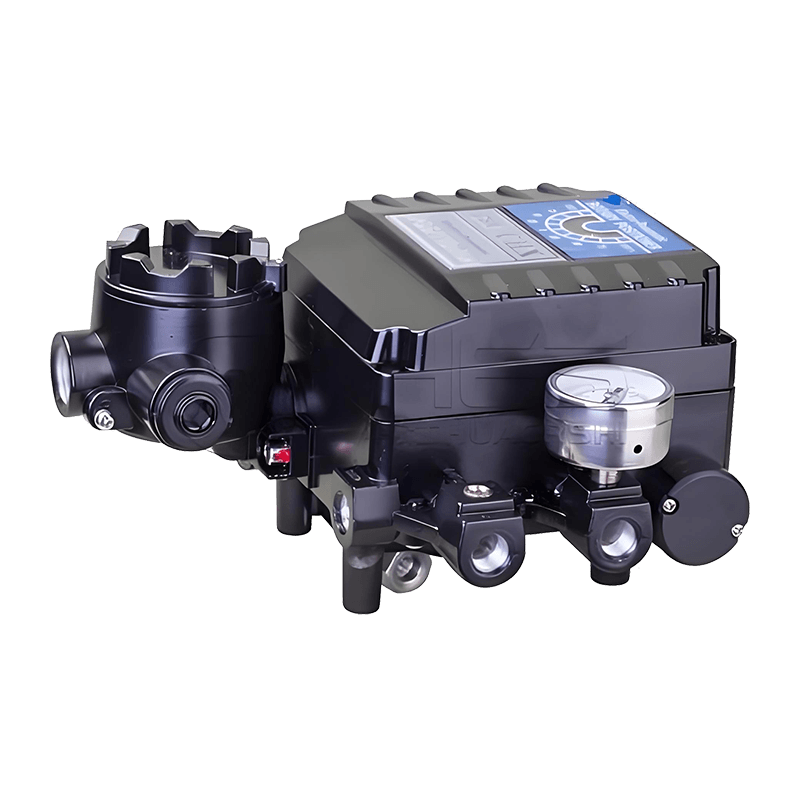

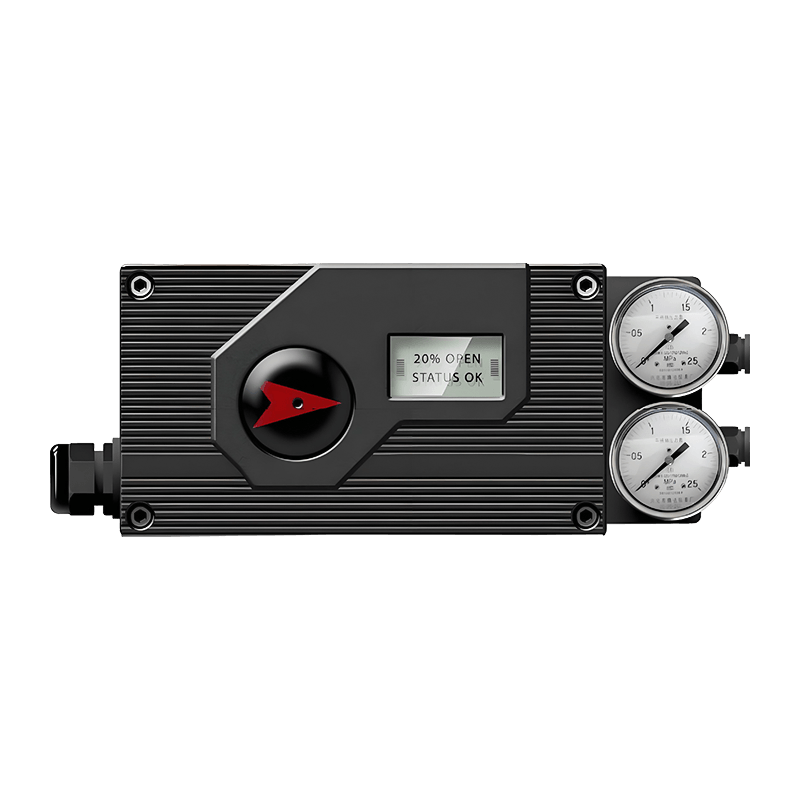

The valve positioner is a crucial component of the control valve, responsible for accurately regulating the valve opening to achieve precise control over flow and pressure. It not only ensures the stable operation of the system but also improves control precision and optimizes energy usage efficiency. As an integral part of the control valve, the valve positioner plays a vital role in ensuring the performance and longevity of the equipment.

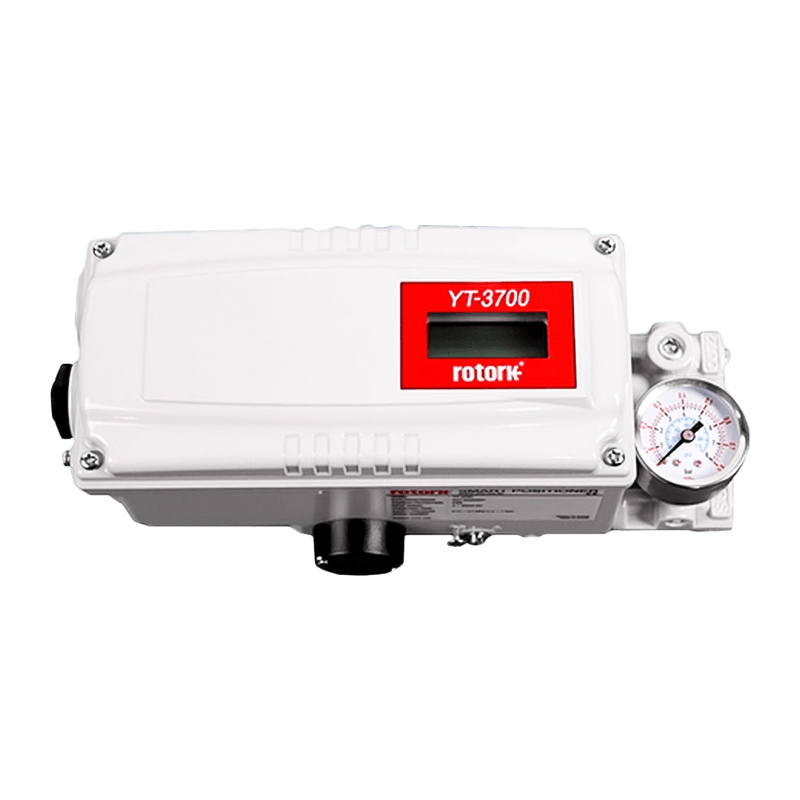

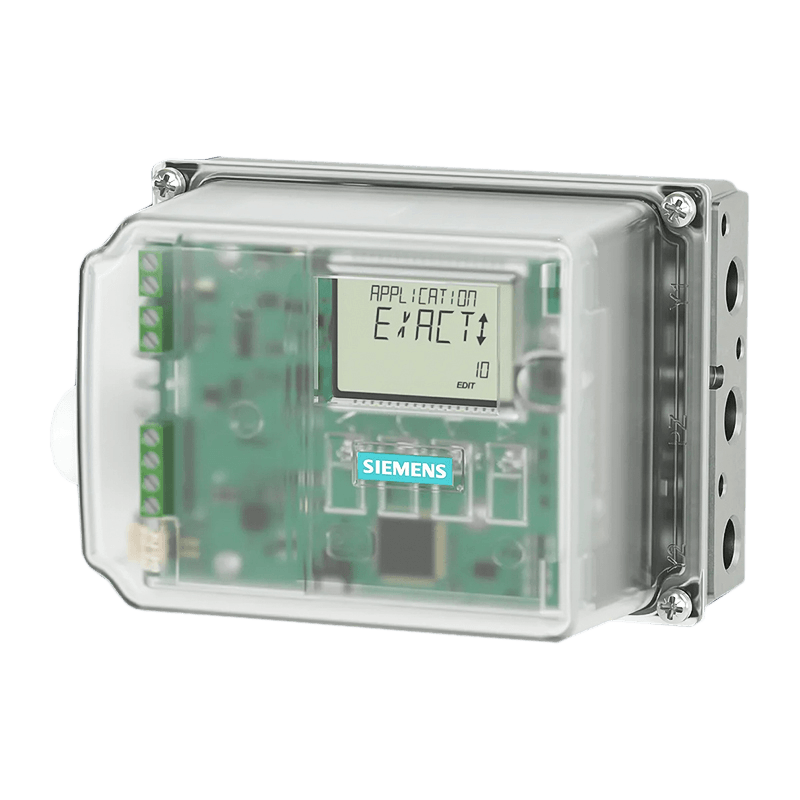

The valve positioners we offer are sourced from internationally renowned brands, including original imported products from Japan, Korea, Germany, and the United States. These products utilize advanced technologies and high-quality materials to deliver stable and reliable performance under various operating conditions. Whether in high-temperature, high-pressure, or complex fluid environments, they ensure precise control of flow and pressure, meeting the diverse needs of industrial applications.

The valve positioner products we select not only enhance the overall efficiency of the system but also reduce the failure rate and maintenance costs. With their high-precision adjustment capabilities, they play an indispensable role in improving production efficiency and ensuring equipment safety.

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

As Valve Positioner Manufacturers and Valve Positioner Company, the Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. Provide Custom Valve Positioner. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

-

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow controlled release of bulk solids, slurries, or liquids by gravity. They are a critical comp...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatically using an electric actuator that adjusts valve position based on control signals. They...

READ MORE -

Key Conclusion: Why Check Valves Are Essential in Fluid Systems Check valves are installed to allow fluid to flow in only one direction and automatically prevent reverse flow without manual intervention. Their...

READ MORE

High-Precision Control in Complex Environments

Advanced valve positioners from Japan, Korea, Germany, and the USA are engineered to deliver unparalleled precision in regulating flow and pressure under complex industrial conditions. These positioners maintain accurate valve positioning even in fluctuating temperatures, variable pressures, or highly viscous fluid systems, ensuring stable operation and consistent process control. Vatten leverages these high-quality components in its automation solutions to optimize energy consumption and extend equipment life.

Key Features That Enhance System Efficiency

Incorporating internationally sourced valve positioners improves both operational reliability and energy efficiency. Key features include:

- High-response actuators for real-time adjustment of valve openings.

- Advanced feedback mechanisms for precise monitoring and control.

- Resistance to harsh environmental conditions including high temperature, high pressure, and corrosive fluids.

- Low hysteresis and minimal deviation for accurate positioning across varying loads.

Integration with Vatten Automated Valve Systems

Vatten designs its control valves and automation systems to fully exploit the performance advantages of imported valve positioners. By integrating these advanced components, Vatten ensures:

- Reduced system downtime through enhanced reliability.

- Lower maintenance costs thanks to durable, long-lasting components.

- Precise flow and pressure control, enabling optimized production efficiency.

- Adaptability to diverse industrial sectors including energy, chemical, water treatment, pharmaceutical, and food processing.

Comparing Valve Positioners from Different Countries

Different manufacturing origins offer unique advantages depending on the industrial application. The following table highlights typical characteristics of valve positioners sourced from Japan, Korea, Germany, and the USA:

| Country | Key Advantages | Application Focus |

| Japan | High-response and compact design | Precision fluid control, small-scale automation |

| Korea | Robust construction and moderate cost | Heavy-duty industrial processes |

| Germany | Precision engineering and durability | Critical systems requiring long-term stability |

| USA | Innovative control technologies | Advanced process automation and monitoring |

Maintenance Strategies for Optimal Performance

To maximize the longevity and reliability of advanced valve positioners, Vatten recommends specific maintenance approaches:

- Regular calibration checks to maintain positioning accuracy.

- Periodic inspection of actuator responsiveness and feedback sensors.

- Use of clean, filtered fluids to reduce wear and avoid contamination.

- Immediate replacement of worn components to prevent system instability.

Conclusion: Maximizing Efficiency with Vatten Valve Solutions

Integrating high-precision valve positioners from Japan, Korea, Germany, and the USA allows Vatten to deliver control systems that combine durability, accuracy, and energy efficiency. These components are central to achieving stable industrial processes, reducing maintenance costs, and optimizing operational performance across a wide range of industries.

English

English Deutsch

Deutsch Indonesia

Indonesia