Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the control valve cannot stably maintain an appropriate position to sustain the predetermined proc...

READ MORE

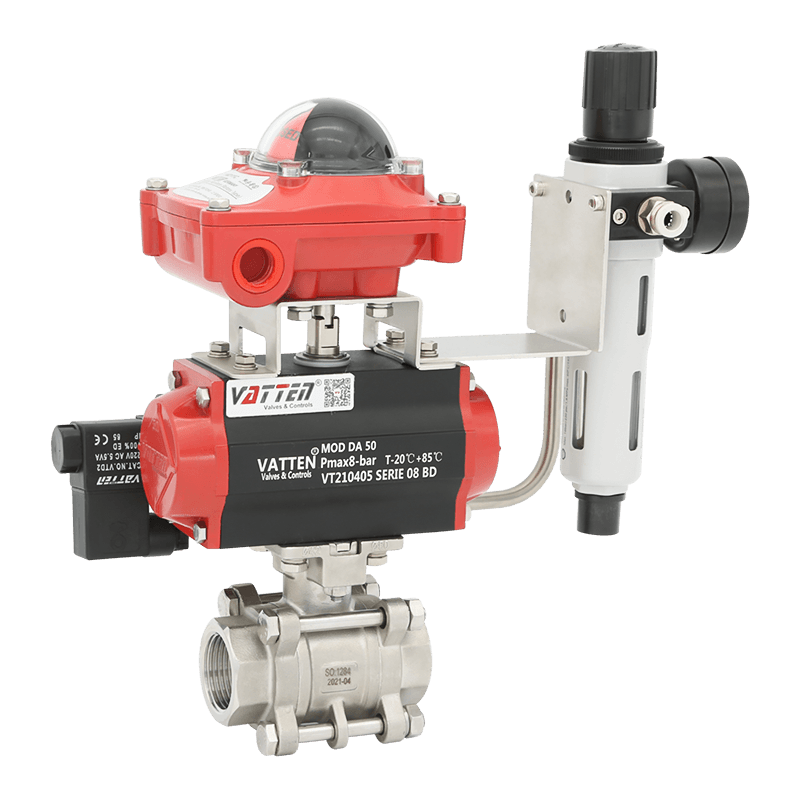

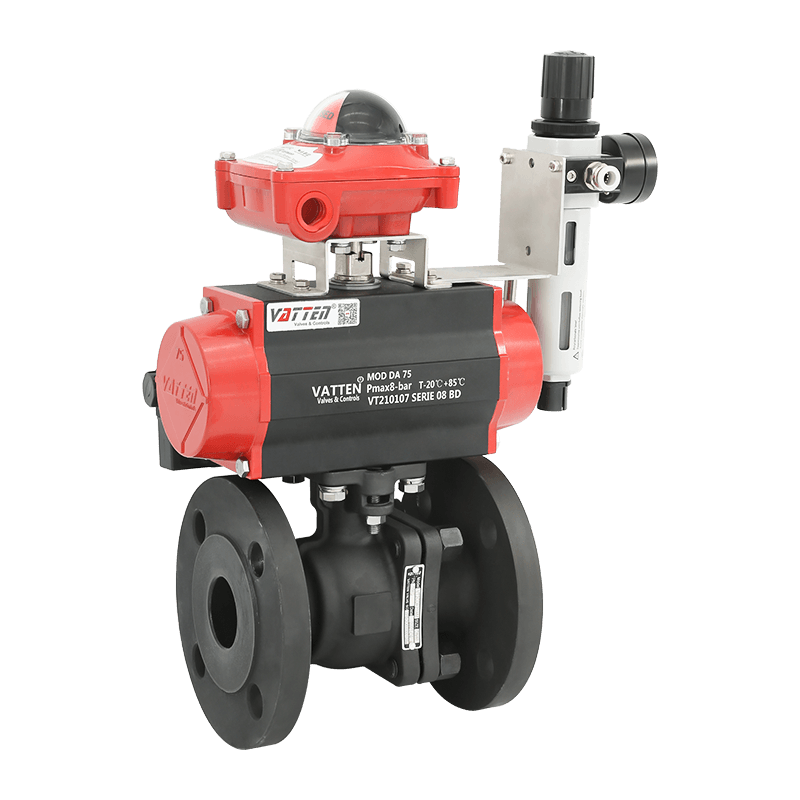

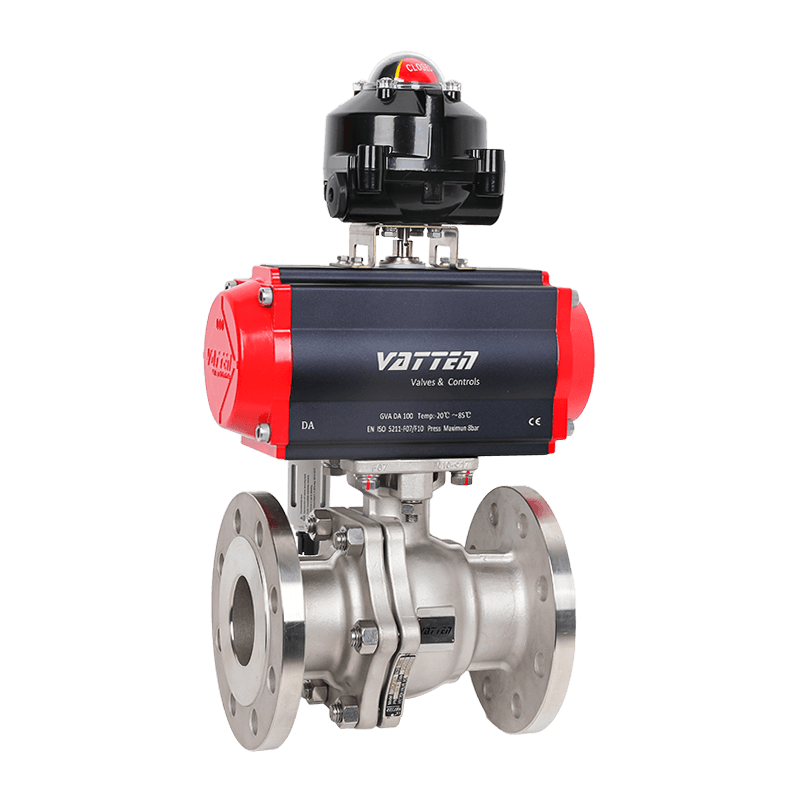

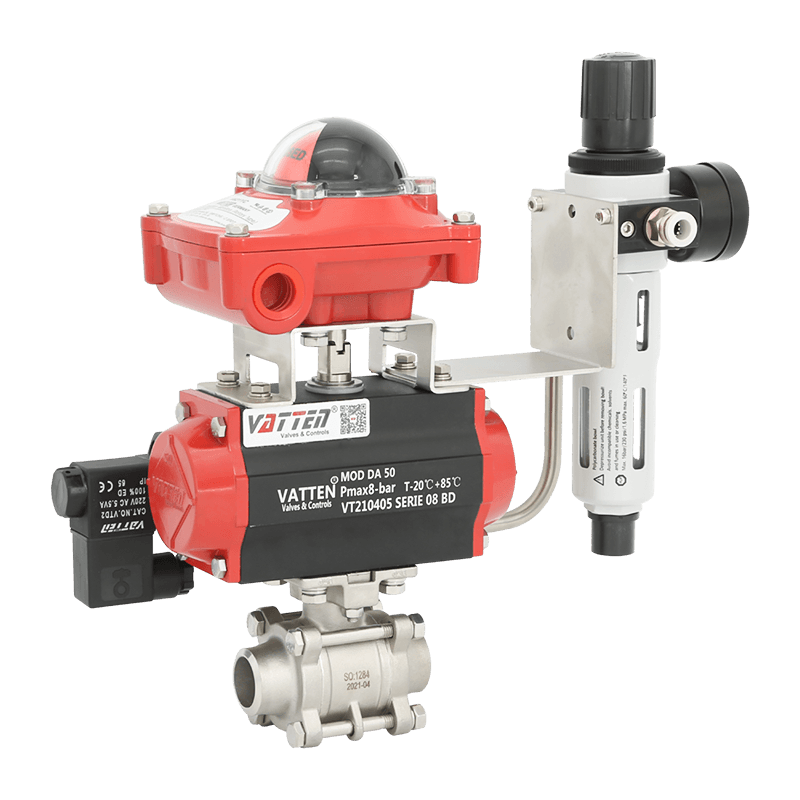

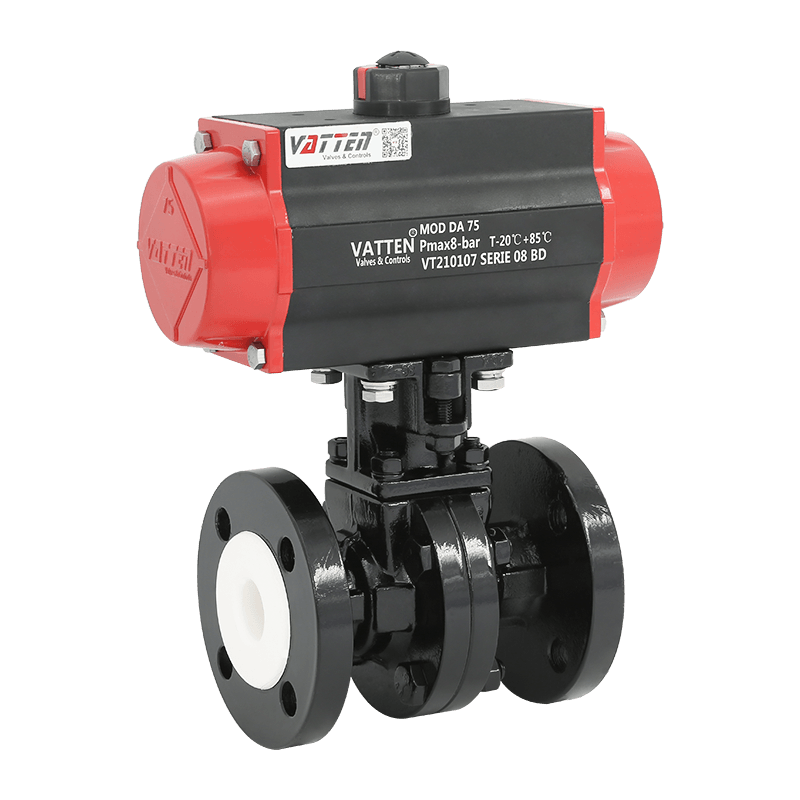

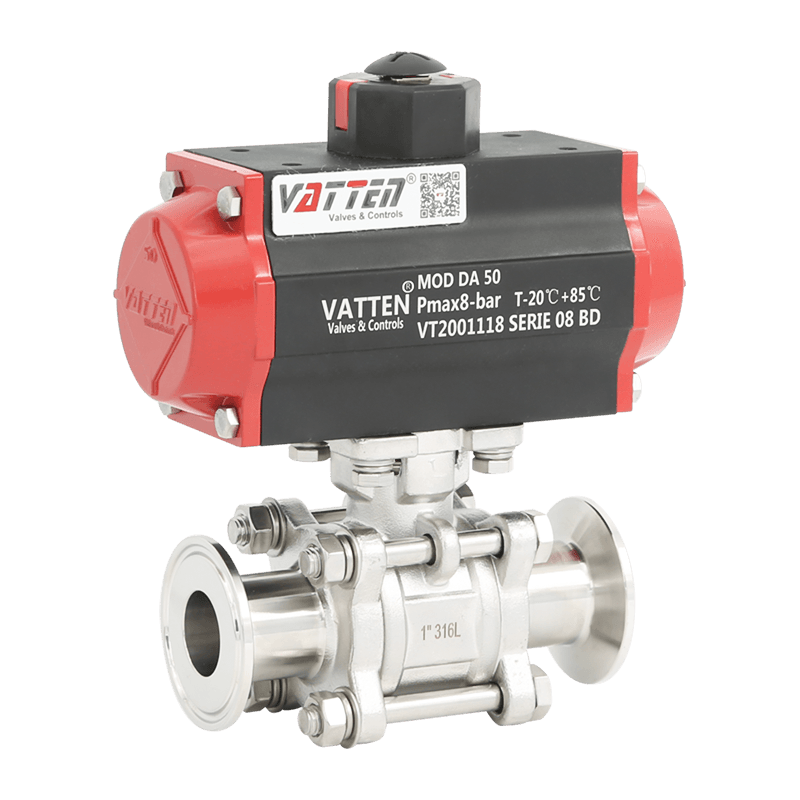

Pneumatic Ball Valves Manufacturers

The VATTEN pneumatic ball valve operates by using the motion of a pneumatic actuator to control the opening and closing of the valve.

The pneumatic actuator features a reinforced aluminum alloy valve body, paired with stainless steel gears, ensuring stability and durability during long-term use.

The pistons on both sides have excellent wear resistance, effectively extending the service life and reducing the need for frequent maintenance.

The cylinder body is anodically hardened, providing strong resistance to oxidation and corrosion, which enhances overall durability.

Our pneumatic actuator is designed with a service life of up to 1 million cycles, making it suitable for high-frequency and high-load working environments.

The ball valve is made from high-platform silica sol material, with a smooth surface that effectively prevents appearance issues such as sand holes and pits.

The unique pressure cap design improves maintenance efficiency, reducing downtime.

The valve has a service life of 800,000 cycles, providing long-term and reliable protection for your pipeline system

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

As Pneumatic Ball Valves Manufacturers and Pneumatic Ball Valves Company, the Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. Provide Custom Pneumatic Ball Valves. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

-

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow controlled release of bulk solids, slurries, or liquids by gravity. They are a critical comp...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatically using an electric actuator that adjusts valve position based on control signals. They...

READ MORE -

Key Conclusion: Why Check Valves Are Essential in Fluid Systems Check valves are installed to allow fluid to flow in only one direction and automatically prevent reverse flow without manual intervention. Their...

READ MORE

Are Pneumatic Ball Valves from Vatten Valve Group Suitable for Both Switching and Throttling Applications?

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, has built a reputation for delivering high-performance valve solutions for critical industries worldwide. With a focus on automatic control ball valves, butterfly valves, and regulating valves, Vatten combines German precision engineering with international manufacturing expertise to provide reliable and innovative fluid control solutions.

In this article, we examine how Vatten valves perform in both switching (on/off) and throttling (flow regulation) applications, offering insights for engineers, procurement specialists, and industrial operators.

Vatten Valve Group: A Global Leader in Valve Technology

Vatten Valve Group operates four advanced manufacturing bases in China—Shanghai, Tianjin, Lishui, and Jiaxing—and maintains branch offices in strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. This global footprint ensures timely delivery, localized technical support, and responsive service to clients across multiple regions.

Rooted in the German tradition of precision manufacturing, Vatten strictly adheres to international quality standards while continuously innovating its product lines. The company offers custom pneumatic ball valves designed to meet specific industrial challenges, providing comprehensive solutions for energy, chemical, water treatment, pharmaceutical, and food processing sectors.

Pneumatic Ball Valves: Designed for Switching and Throttling

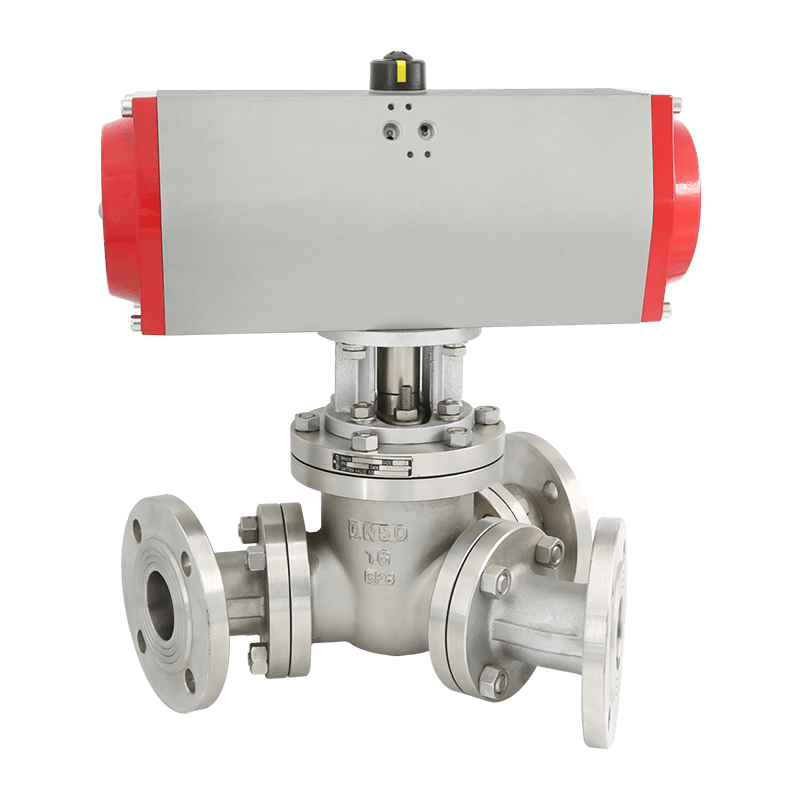

Vatten’s pneumatic ball valves are engineered to excel in both switching and throttling operations, combining durability, precision, and ease of maintenance.

Robust Actuator Design

The valve’s pneumatic actuator features a reinforced aluminum alloy body paired with stainless steel gears, ensuring stability and long-term reliability. Dual pistons provide excellent wear resistance, reducing the need for frequent maintenance even under high-frequency or high-load operating conditions.

The anodically hardened cylinder body adds strong protection against corrosion and oxidation, enhancing the actuator’s durability in harsh environments. With a service life of up to 1 million cycles, Vatten pneumatic actuators are ideal for continuous operation in demanding industrial systems.

High-Performance Valve Body

The ball valve itself is made from high-platform silica sol material, providing a smooth, defect-free surface that resists common issues such as sand holes and pits. This ensures consistent operation and a long service life of up to 800,000 cycles, offering reliable protection for your pipeline systems.

A unique pressure cap design simplifies maintenance procedures, reducing downtime and improving overall system efficiency—an essential feature for industries where operational continuity is critical.

Suitability for Switching Applications

Vatten valves excel in switching applications, where rapid and precise opening and closing are required. The combination of high-strength materials, robust actuator design, and precise ball alignment ensures minimal leakage, quick response times, and reliable on/off control. These characteristics make Vatten valves suitable for critical flow isolation tasks in chemical, pharmaceutical, and water treatment processes.

Suitability for Throttling Applications

For throttling or flow regulation, Vatten valves maintain stable and controllable flow rates, thanks to the smooth surface of the ball and precise actuator control. The design minimizes turbulence and cavitation while providing reliable flow modulation, making the valves suitable for processes that require gradual or variable flow adjustments, such as energy systems or industrial chemical mixing.

The valve’s high durability and long service life ensure consistent performance, even under repeated throttling operations, while the actuator’s precision allows fine control of flow without excessive wear or maintenance needs.

Conclusion: Reliable Solutions for Dual Applications

With their combination of robust design, advanced materials, and long operational life, Vatten pneumatic ball valves are highly suitable for both switching and throttling applications. Supported by Vatten Valve Group’s global manufacturing and service network, these valves provide consistent performance, reduced maintenance, and operational efficiency across a wide range of industries.

By leveraging Vatten’s expertise and innovative solutions, industrial operators can confidently implement fluid control systems that meet the most demanding requirements, whether for rapid on/off switching or precise flow regulation.

English

English Deutsch

Deutsch Indonesia

Indonesia