Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the cont...

READ MORE

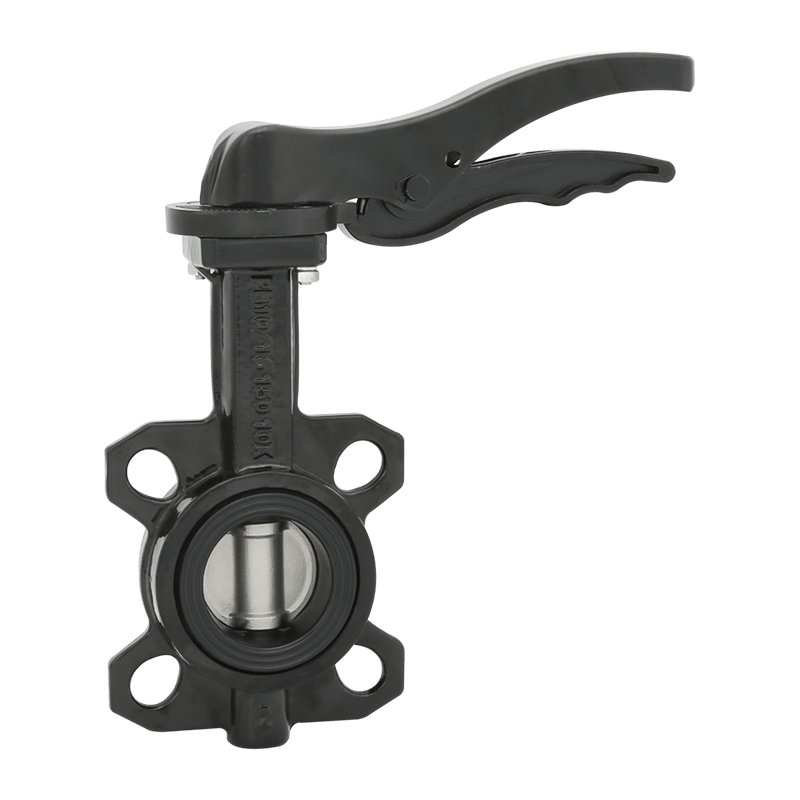

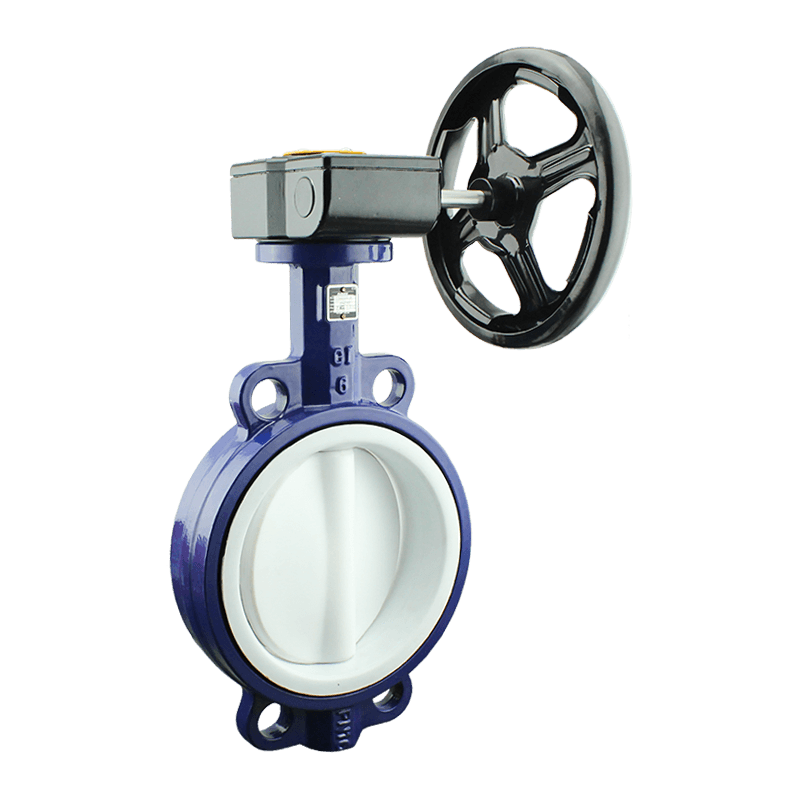

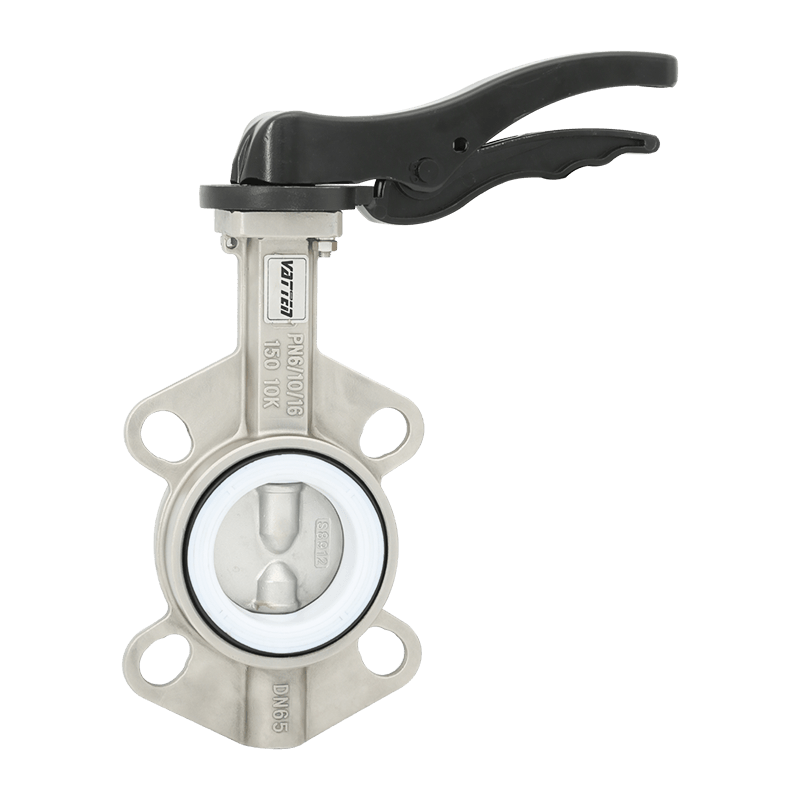

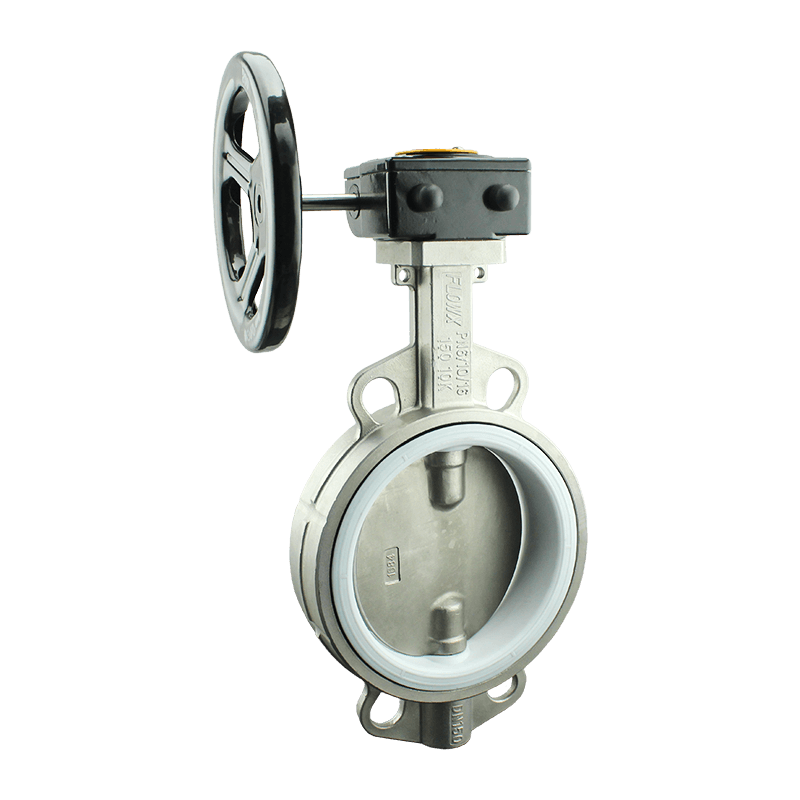

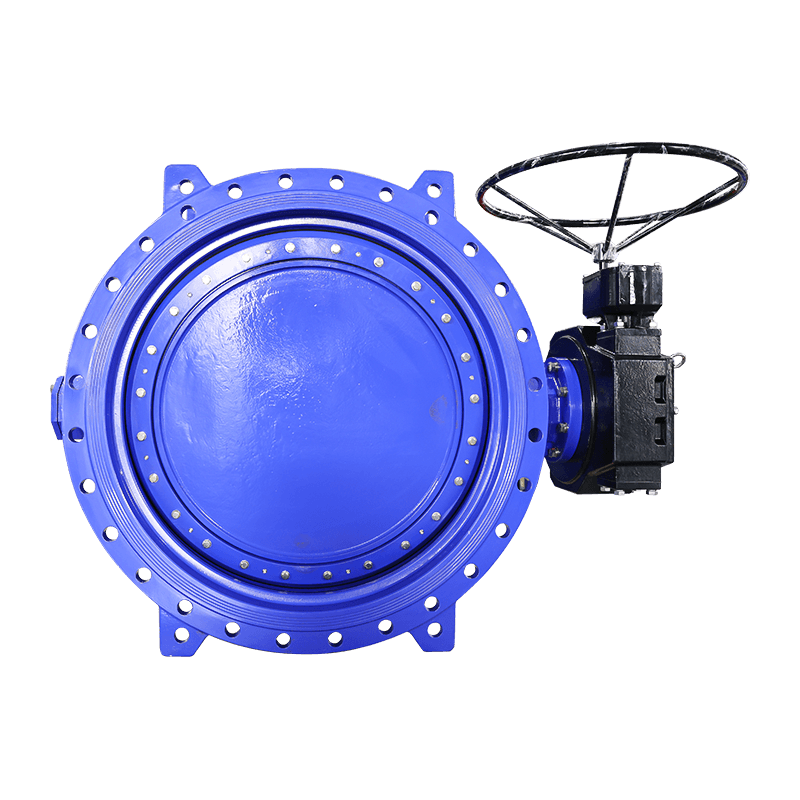

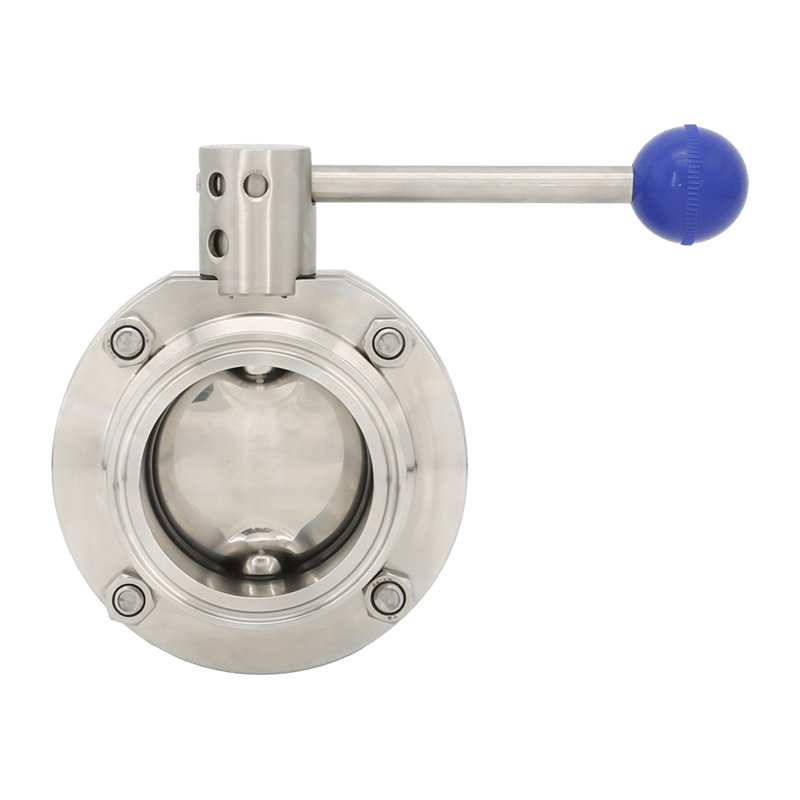

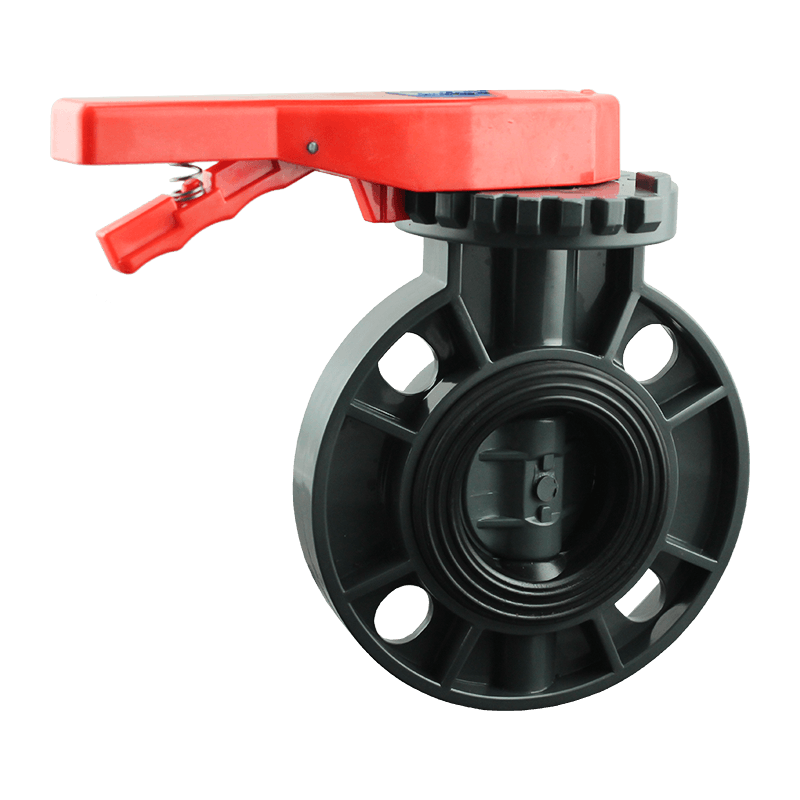

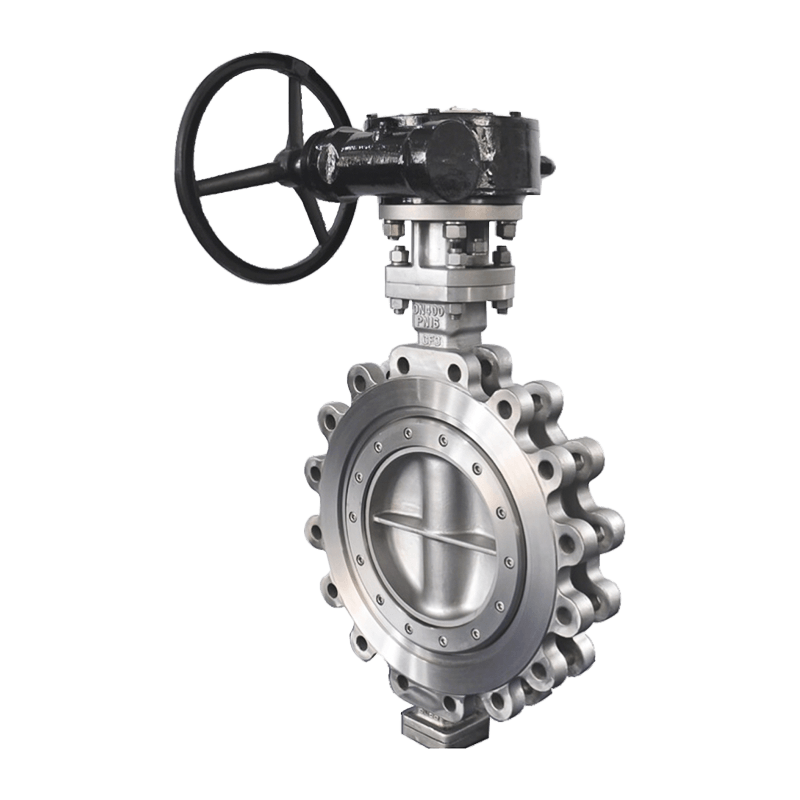

Butterfly Valves Suppliers

VATTEN offers a comprehensive range of butterfly valves designed to meet diverse industry requirements. Our product line includes manual, pneumatic, and electric butterfly valves, each crafted from high-quality materials to ensure durability and reliability. We prioritize performance, ensuring that every valve is equipped with components suited to specific operational needs.

Our butterfly valves are engineered with flexibility in mind, offering a variety of specialized designs and material options to cater to unique operational environments. Whether you’re dealing with extreme temperatures, corrosive substances, or high-pressure conditions, VATTEN's valves are designed to excel in challenging scenarios.

Each valve undergoes rigorous testing to meet strict performance and longevity standards. This ensures that our customers receive a product that not only performs at the highest level but also offers long-term value and reliability in the field. With VATTEN butterfly valves, you can trust that your system will operate efficiently and safely for years to come.

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

As Butterfly Valves Suppliers and Butterfly Valves Factory, the Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. Provide Custom Butterfly Valves. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

-

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow co...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatic...

READ MORE -

Key Conclusion: Why Check Valves Are Essential in Fluid Systems Check valves are installed to allow fluid to flow in on...

READ MORE -

Such a scene often occurs during control valve selection meetings: The procurement manager asked: "Why not use this bal...

READ MORE

Optimizing Butterfly Valve Performance in Piping Systems

Butterfly valves, while simple in structure, require careful consideration in installation and operation to achieve optimal performance. Key factors include pipeline alignment, torque specifications, and flow dynamics. Misalignment or excessive torque can lead to premature wear of the valve disc and seat, reducing operational lifespan. Ensuring smooth, unobstructed flow upstream and downstream of the valve prevents turbulence that can compromise sealing efficiency.

Material Selection for High-Corrosion Environments

In industrial environments involving aggressive chemicals or high moisture, selecting the right material for butterfly valve components is critical. Common options include stainless steel, ductile iron with epoxy coating, and PTFE-lined discs. Each material offers distinct advantages:

- Stainless Steel: Excellent corrosion resistance, suitable for acidic or saline environments.

- Ductile Iron with Epoxy: Cost-effective, provides good wear resistance in moderately corrosive applications.

- PTFE-Lined Discs: Ideal for handling aggressive chemical media, ensuring long-term sealing performance.

Control and Automation Strategies

Butterfly valves are frequently integrated with actuators for automated process control. Pneumatic and electric actuators allow precise modulation of flow, enabling energy-efficient system operation. Implementing positioners with feedback loops enhances control accuracy, particularly in systems with fluctuating pressure or temperature conditions.

Pneumatic vs Electric Actuation

Pneumatic actuators provide fast response and are suitable for hazardous environments due to intrinsic safety, whereas electric actuators offer precise position control and are easier to integrate with digital monitoring systems. Selecting the actuator depends on the required speed, accuracy, and system integration requirements.

Maintenance Practices for Longevity

Routine maintenance of butterfly valves ensures reliability and minimizes downtime. Key practices include regular lubrication of the stem, inspection of the seat for wear, and checking actuator performance. Additionally, cleaning debris from the disc and sealing surfaces prevents leaks and reduces mechanical strain.

Performance Metrics and Troubleshooting

Monitoring butterfly valve performance involves evaluating pressure drop, leakage rate, and actuation torque. Common issues include chatter, incomplete sealing, and actuator failure. The following table summarizes common issues and corrective actions:

| Issue | Possible Cause | Corrective Action |

| Valve leakage | Worn seat or improper alignment | Replace seat, realign valve |

| High actuation torque | Debris on disc, insufficient lubrication | Clean valve, lubricate stem |

| Chattering during flow | High flow velocity, unstable pressure | Install flow stabilizer or reduce upstream turbulence |

English

English Deutsch

Deutsch Indonesia

Indonesia