Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the control valve cannot stably maintain an appropriate position to sustain the predetermined proc...

READ MORE

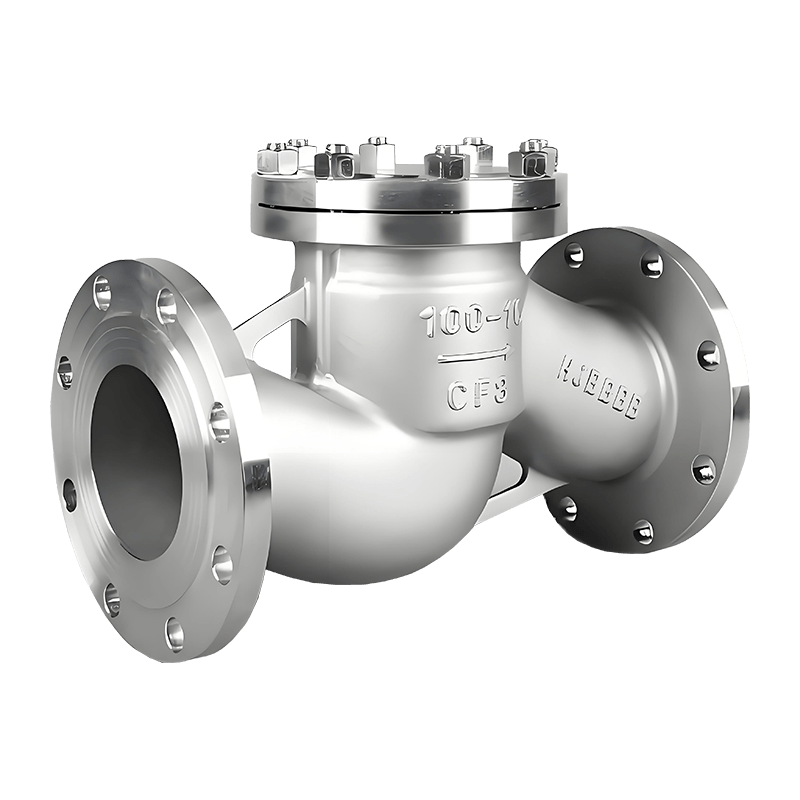

Lift Check Valves Manufacturers

The lift check valve is widely used in various liquid flow systems due to its simple structure and straightforward working principle. This valve effectively prevents the backflow of liquids in both horizontal and vertical pipelines, avoiding potential system damage or instability caused by backflow. Its design allows the valve to respond flexibly to changes in pipeline pressure, ensuring that fluid flows in only one direction.

In addition, lift check valves typically have a long service life, thanks to their wear-resistant design and the use of high-quality materials. The simple mechanical structure of the valve also makes maintenance and replacement relatively easy, reducing operational and maintenance costs.

Our company's lift check valves, with stable quality and rigorous manufacturing processes, meet the demands of various application environments, ensuring efficient and safe system operation.

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

As Lift Check Valves Manufacturers and Lift Check Valves Company, the Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. Provide Custom Lift Check Valves. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

-

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow controlled release of bulk solids, slurries, or liquids by gravity. They are a critical comp...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatically using an electric actuator that adjusts valve position based on control signals. They...

READ MORE -

Key Conclusion: Why Check Valves Are Essential in Fluid Systems Check valves are installed to allow fluid to flow in only one direction and automatically prevent reverse flow without manual intervention. Their...

READ MORE

Lift Check Valves: The Precision Guardians of Unidirectional Fluid Flow

The Lift Check Valve (LCV) is an essential automatic valve in industrial piping systems, designed to ensure that fluid (liquid or gas) flows exclusively in a predetermined direction, thereby preventing any backflow. Known for their robust structure and reliable sealing, LCVs are particularly well-suited for applications involving high pressure, high temperature, or those demanding rapid closure response.

Rooted in the German tradition of precision manufacturing, companies like Vatten Valve Group—a globally renowned industrial automation valve enterprise originating from Saarland, Germany—uphold the strictest standards in the design and production of such critical flow components.

Core Mechanism: Pressure Drive and Gravity Reset

The operation of the Lift Check Valve is purely automatic, relying entirely on the fluid’s pressure dynamics and gravity:

- Opening: When upstream pressure overcomes the combined forces of downstream pressure, the weight of the closing element (disc or piston), and any auxiliary spring tension, the fluid pushes the element vertically upward, away from the valve seat.

- Closing: As flow decreases or reversal occurs, gravity and the pressure of the returning medium swiftly force the disc/piston back onto the seat. This quick, short-stroke closure is highly effective at mitigating water hammer in high-velocity systems.

This commitment to reliable, high-performance fluid control is central to the mission of enterprises specializing in automated solutions. Vatten Valve Group specifically leverages their exceptional technological expertise to deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

Structure and Principal Design Types

The design of LCVs is focused on the shape and guidance of the internal closing component:

1. Piston Lift Check Valve

This type uses a cylindrical piston precisely guided within the bonnet or internal guides. This robust guidance ensures stability and anti-chatter performance, even under high flow rates. Piston-type LCVs are typically employed in systems handling steam, gas, air, and high-pressure, clean liquids. Their common Z-flow pattern provides superior sealing integrity but results in a higher pressure drop compared to other designs.

2. Ball Lift Check Valve

The Ball LCV uses a precision-ground spherical body as the closing element. Due to the rotating nature of the ball, it is highly suitable for viscous fluids or media containing a small number of solid particles, as the constant change in seating position minimizes localized wear. These Lift Check Valves often feature a Y-pattern or straight-through body design to better accommodate particulate matter and reduce flow resistance.

Performance Advantages and Engineering Applications

LCVs offer distinct advantages that make them the preferred choice in challenging applications:

- High Sealing Reliability: The linear contact between the disc/piston and the seat ensures a tight, high-integrity seal, meeting stringent zero-leakage requirements often found in high-pressure systems.

- High Pressure/Temperature Endurance: Constructed from robust materials, often using forged bodies, LCVs are built to withstand the extreme pressures and temperatures prevalent in industries served by companies like Vatten Valve Group.

- Fast Response and Anti-Chatter: The short vertical stroke enables rapid closure, making the valve resistant to the vibration and oscillation that can occur in pulsating flow conditions.

Vatten Valve Group, while specializing in core products such as automatic control ball valves, butterfly valves, and regulating valves, maintains its focus on automatic control valves while strictly adhering to international quality standards across its entire product line, including check valves. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

Key Industrial Applications

The superior sealing capability and durability of Lift Check Valves make them indispensable across various critical sectors:

- Power Plants: Used in feedwater pump discharge lines and main steam lines to prevent reverse flow.

- Compressor Systems: Installed at the discharge of reciprocating and centrifugal compressors to protect equipment from damaging back pressure.

- High-Pressure Chemical Injection: Employed in chemical and oil & gas operations to ensure precise, unidirectional injection of high-pressure fluids.

Vatten Valve Group delivers these crucial components and the necessary technical expertise to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing, supporting essential infrastructure globally.

English

English Deutsch

Deutsch Indonesia

Indonesia