Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the cont...

READ MORE

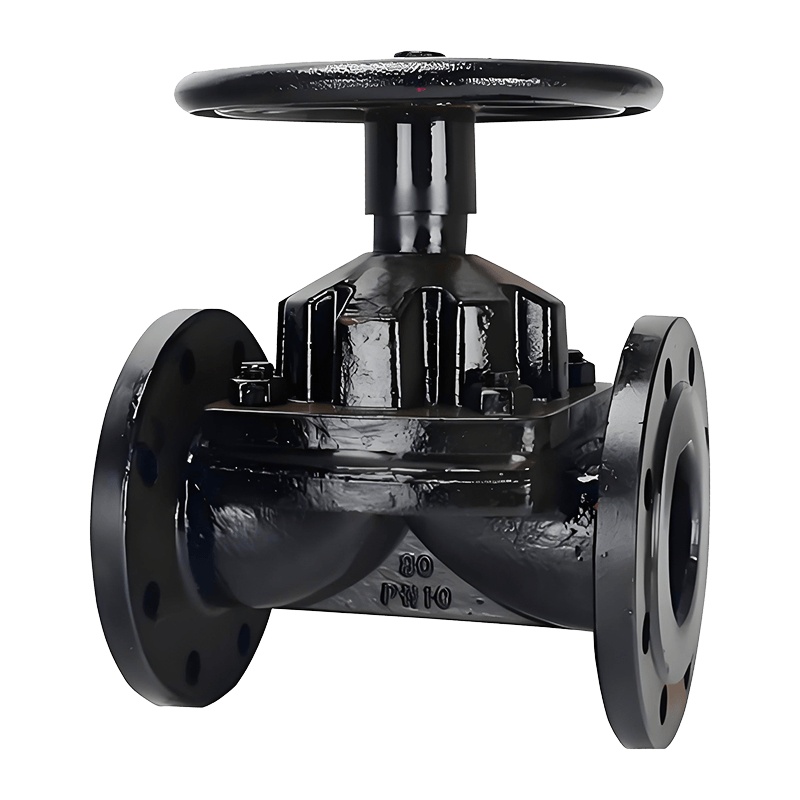

Diaphragm Valves Suppliers

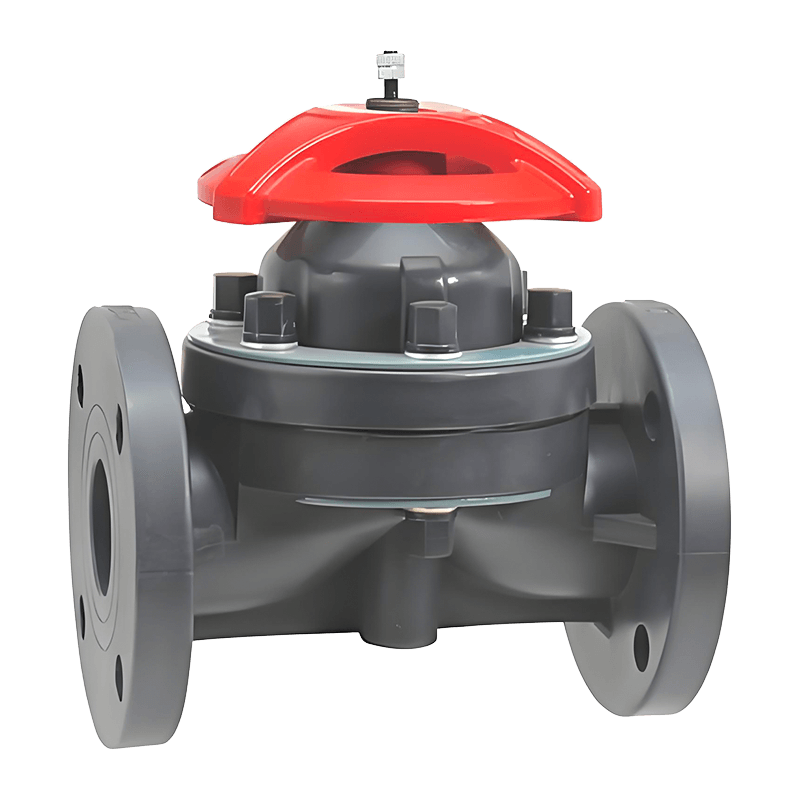

VATTEN's Diaphragm Valve series is designed to meet the needs of a wide range of industries, offering flexible solutions for various pipeline configurations. The valves are available with a choice of pneumatic actuators, which come with either aluminum alloy or plastic heads, providing durability and versatility for different operational environments.

One of the standout features of these valves is the option for pharmaceutical-grade interior polishing. This ensures that the internal surfaces meet the highest hygiene standards, making them suitable for industries where cleanliness and precision are paramount.

Additionally, VATTEN's Diaphragm Valves are crafted from a variety of materials, enabling them to perform reliably in diverse applications. Whether used in harsh industrial environments or specialized sectors like pharmaceuticals, these valves are built to deliver consistent performance and long-lasting reliability.

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

As Diaphragm Valves Suppliers and Diaphragm Valves Factory, the Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. Provide Custom Diaphragm Valves. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

-

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow co...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatic...

READ MORE -

Key Conclusion: Why Check Valves Are Essential in Fluid Systems Check valves are installed to allow fluid to flow in on...

READ MORE -

Such a scene often occurs during control valve selection meetings: The procurement manager asked: "Why not use this bal...

READ MORE

Material Compatibility in Diaphragm Valves Selection

Selecting the proper diaphragm and body material is crucial to ensure valve longevity and chemical resistance. For example, PTFE diaphragms are often used in aggressive chemical processes due to their resistance to acids and solvents, while EPDM or natural rubber options are better suited for water treatment or low-corrosive media. Matching materials should consider temperature, pH, and fluid composition rather than relying solely on general compatibility charts.

Optimizing Diaphragm Valve Performance in Vacuum Applications

When used in vacuum lines, diaphragm valves must maintain a tight seal without deforming under negative pressure. Valves with reinforced diaphragms or those designed with a compressor-support structure prevent suction collapse and leakage. Regular vacuum integrity tests are recommended after prolonged operation, as the diaphragm’s elasticity can degrade over time in low-pressure environments.

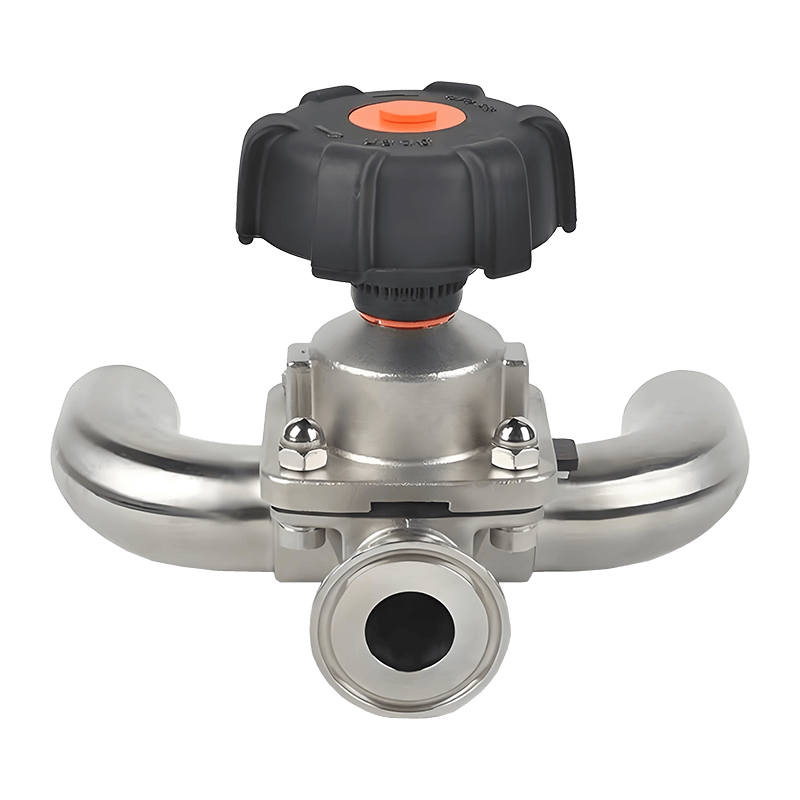

Minimizing Dead Space in Hygienic Systems

In pharmaceutical and food-grade installations, minimizing dead space within diaphragm valves is critical to avoid microbial growth or residue accumulation. Compact, zero-dead-leg designs allow complete drainability, especially when valves are installed at an angle relative to the pipeline. This configuration also supports effective clean-in-place (CIP) and steam-in-place (SIP) processes, reducing the need for disassembly and manual cleaning.

Maintenance Practices for Extending Diaphragm Life

Proper maintenance can significantly extend diaphragm service life. Key practices include:

- Avoiding excessive closing torque that could deform the diaphragm or seat area.

- Inspecting for surface cracking, blistering, or detachment from the compressor plate during scheduled shutdowns.

- Replacing diaphragms on a cycle-based schedule rather than waiting for visible leakage, especially in high-cycle or high-temperature applications.

Comparative Analysis of Manual vs. Pneumatic Diaphragm Valves

Choosing between manual and pneumatic operation impacts both efficiency and control precision. Pneumatic diaphragm valves offer better repeatability and are ideal for automated systems, while manual valves provide simplicity and are suitable for low-frequency operations or maintenance bypasses.

| Feature | Manual Valve | Pneumatic Valve |

| Control Precision | Low to Moderate | High |

| Automation Compatibility | Limited | Excellent |

| Maintenance Frequency | Low | Moderate |

| Installation Cost | Lower | Higher |

Thermal Expansion and Valve Body Stress

Diaphragm valves operating in systems with frequent temperature changes must account for thermal expansion of both the valve body and the piping. Using composite or glass-reinforced plastic bodies can reduce stress fractures. Installing flexible couplings near valve connections helps accommodate expansion, preventing mechanical distortion that might cause leakage or diaphragm misalignment.

Flow Coefficient (Cv) Considerations in System Design

While diaphragm valves typically have lower flow coefficients than ball or butterfly valves, proper sizing can optimize flow without sacrificing control. Engineers should calculate Cv based on actual flow requirements and pressure drop tolerance. Oversized valves may lead to unstable throttling, while undersized ones restrict throughput and increase wear on the diaphragm surface.

English

English Deutsch

Deutsch Indonesia

Indonesia