Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the cont...

READ MORE

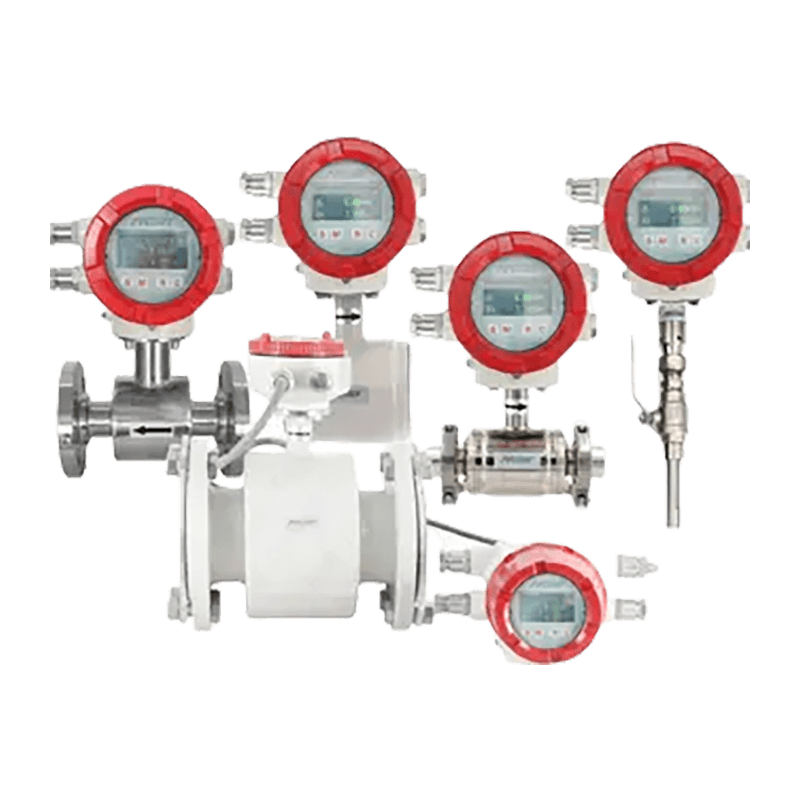

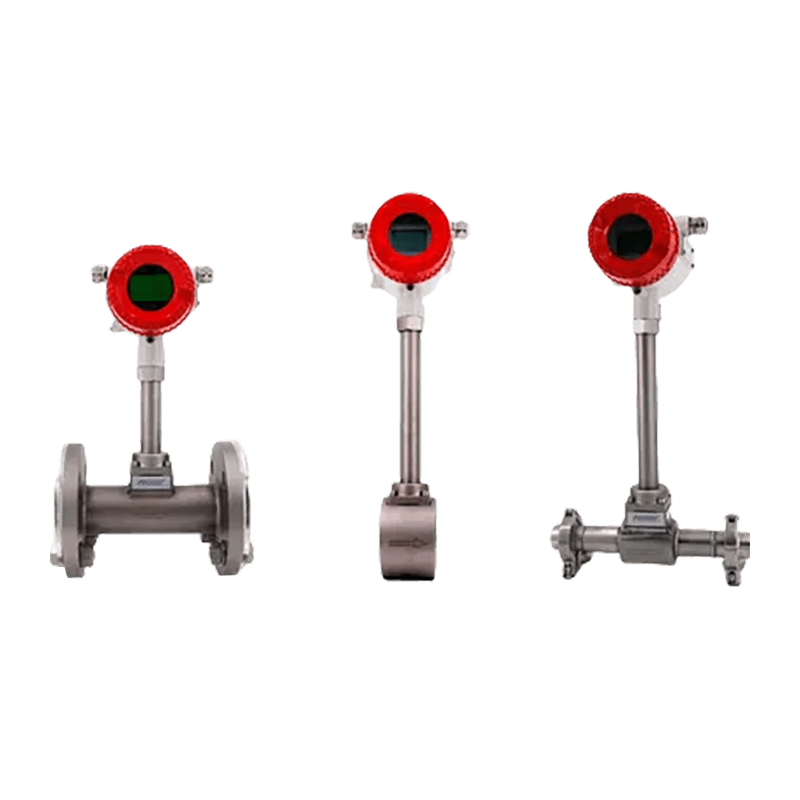

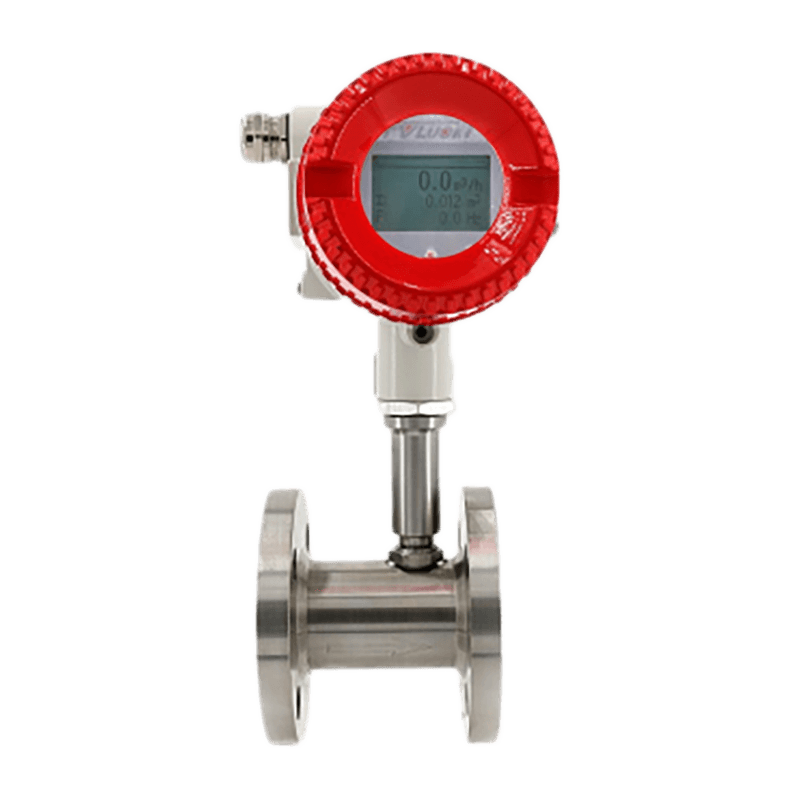

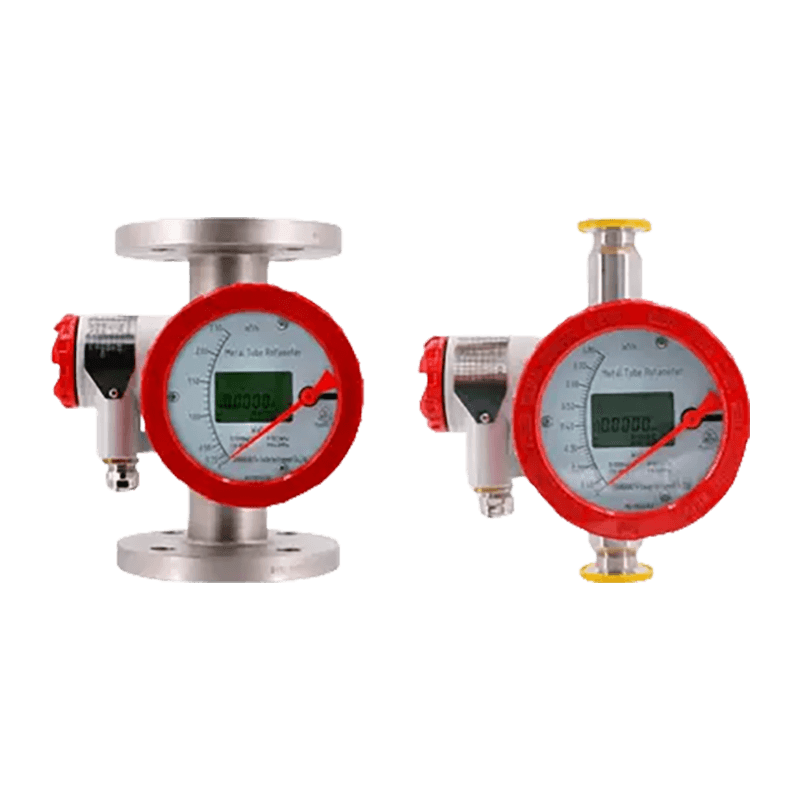

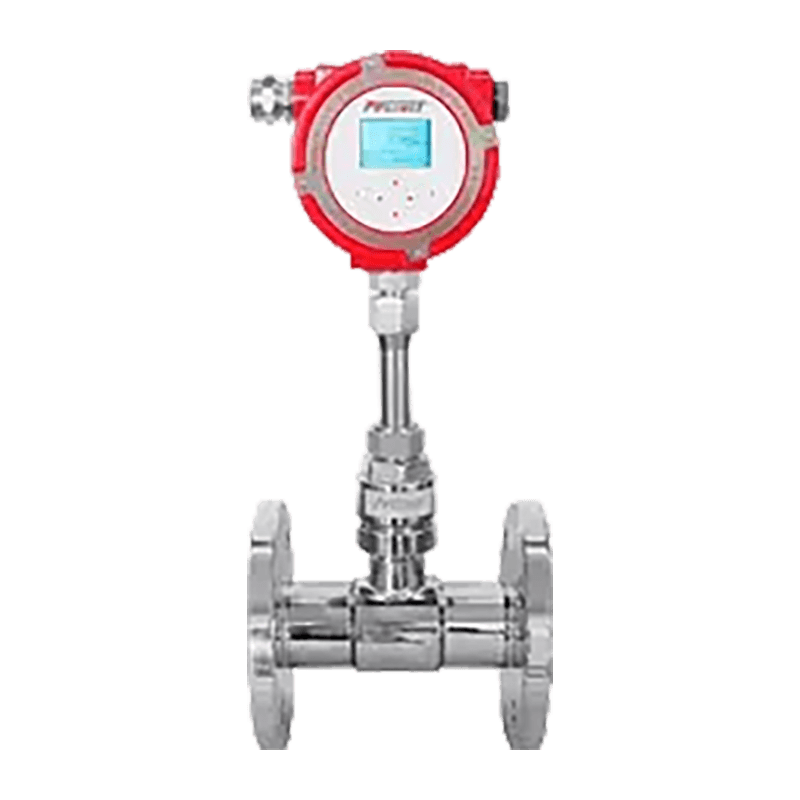

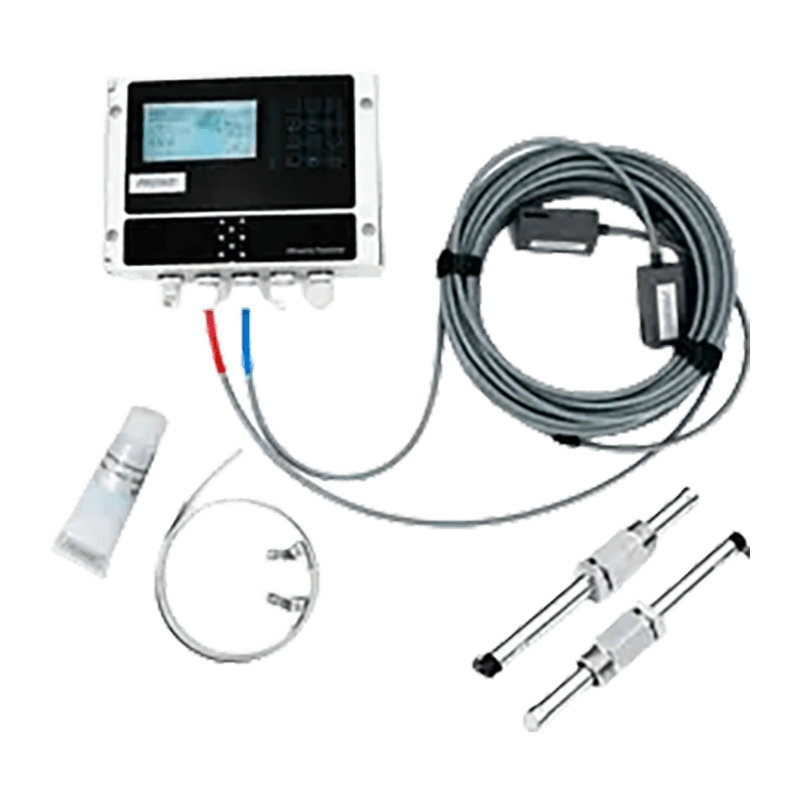

Industrial Flow Meters Manufacturers

FvLuoky offers a diverse portfolio of flow instruments, including electromagnetic flowmeters, vortex flowmeters, turbine flowmeters, metal tube rotameters, thermal gas flowmeters, and ultrasonic flowmeters. Engineered with precision and high-quality materials, our flow instruments are capable of handling liquids, gases, and steam across a wide range of industrial applications. Each product undergoes rigorous testing to ensure accuracy and stability under demanding conditions such as high pressure, corrosive environments, or complex processes. With flexible solutions and customization options, FvLuoky flow instruments are the ideal choice for energy efficiency, process optimization, and reliable measurement.

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

As Industrial Flow Meters Manufacturers and Flow Instruments Company, the Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. Provide Custom Industrial Flow Meters. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

-

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow co...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatic...

READ MORE -

Key Conclusion: Why Check Valves Are Essential in Fluid Systems Check valves are installed to allow fluid to flow in on...

READ MORE -

Such a scene often occurs during control valve selection meetings: The procurement manager asked: "Why not use this bal...

READ MORE

Accuracy Challenges in Industrial Flow Meters

Industrial flow meters measure fluid flow rates in complex processes where viscosity, temperature, and pressure can vary significantly. Accuracy depends on proper meter selection, installation, and calibration. For example, turbine flow meters are sensitive to fluid viscosity changes, while electromagnetic meters require conductive fluids for proper operation. Ensuring straight pipe runs upstream and downstream, minimizing vibrations, and performing periodic calibration against reference standards are essential for maintaining measurement accuracy.

Comparing Differential Pressure, Coriolis, and Ultrasonic Flow Instruments

Different flow instruments suit specific applications based on the nature of the fluid and process requirements. The table below highlights key differences among common flow measurement technologies:

| Flow Meter Type | Measurement Principle | Suitable Fluids | Advantages |

| Differential Pressure | Measures pressure drop across an orifice or restriction | Liquids and gases with moderate flow | Simple, cost-effective, wide range of applications |

| Coriolis | Measures mass flow using Coriolis force on vibrating tubes | Liquids and gases, even viscous fluids | High accuracy, direct mass flow measurement |

| Ultrasonic | Measures flow velocity using sound waves | Clean or slightly contaminated liquids | Non-intrusive, no pressure drop, suitable for large pipes |

Installation Effects on Flow Measurement Accuracy

The installation location, pipe orientation, and straight-run length significantly affect flow measurement accuracy. Swirling flows or turbulence caused by valves, elbows, or pumps upstream of the meter can introduce errors. Using flow conditioners, ensuring proper alignment, and providing recommended straight-pipe lengths before and after the meter minimize these effects. For multiphase fluids, additional considerations include sensor placement and damping devices to reduce pulsation interference.

Maintenance Best Practices for Flow Instruments

Regular maintenance ensures reliability and prevents downtime in industrial systems. Flow instruments may require cleaning, calibration, and verification of signal integrity. Sensors exposed to abrasive or corrosive fluids may need periodic replacement or protective coatings. Monitoring for drift or abnormal readings allows early detection of fouling, blockage, or mechanical wear. Proper documentation of maintenance activities aids in traceability and ensures compliance with process safety standards.

- Inspect sensor surfaces for buildup or erosion.

- Verify signal output against calibrated reference meters.

- Check for vibration or pipe misalignment that could affect readings.

- Replace worn seals or gaskets to prevent leakage in flow paths.

Energy Efficiency Considerations in Flow Measurement

Certain flow measurement technologies impact system pressure and energy consumption. For example, differential pressure meters create a pressure drop that increases pumping energy requirements. Selecting low-loss flow elements, such as ultrasonic or magnetic meters, reduces system head loss. Additionally, accurate flow measurement allows optimization of process control, reducing over-pumping or unnecessary fluid circulation, which enhances overall energy efficiency and cost-effectiveness.

Smart Flow Instruments and Digital Communication

Modern industrial flow meters often feature digital outputs and smart communication protocols such as HART, Modbus, or Foundation Fieldbus. These transmitters can provide real-time flow data, diagnostics, and historical trends to centralized control systems. Predictive maintenance is enhanced by monitoring flow anomalies, sensor health, and calibration status. Integration with industrial IoT networks enables remote monitoring, reducing maintenance visits and enhancing operational efficiency in large-scale plants.

Handling Viscous and Multiphase Fluids

Flow measurement for viscous or multiphase fluids presents unique challenges. Viscous fluids can reduce turbine or paddlewheel meter responsiveness, while multiphase fluids introduce measurement errors due to density fluctuations. Selecting mass flow meters such as Coriolis or electromagnetic types mitigates these issues. Additionally, flow conditioners, straight-run pipe requirements, and proper calibration for density and viscosity compensate for complex flow characteristics, ensuring reliable process data.

Flow Instrument Diagnostics and Troubleshooting

Advanced flow instruments provide diagnostic functions that help detect abnormal conditions, such as sensor drift, flow blockages, or cavitation. Monitoring signal consistency, response time, and vibration patterns allows operators to identify issues before they affect the process. Regular review of diagnostic logs enables proactive maintenance and reduces the risk of unexpected downtime. Some smart meters also support remote firmware updates, allowing optimization of algorithms for specific process conditions.

English

English Deutsch

Deutsch Indonesia

Indonesia