Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the control valve cannot stably maintain an appropriate position to sustain the predetermined proc...

READ MORE

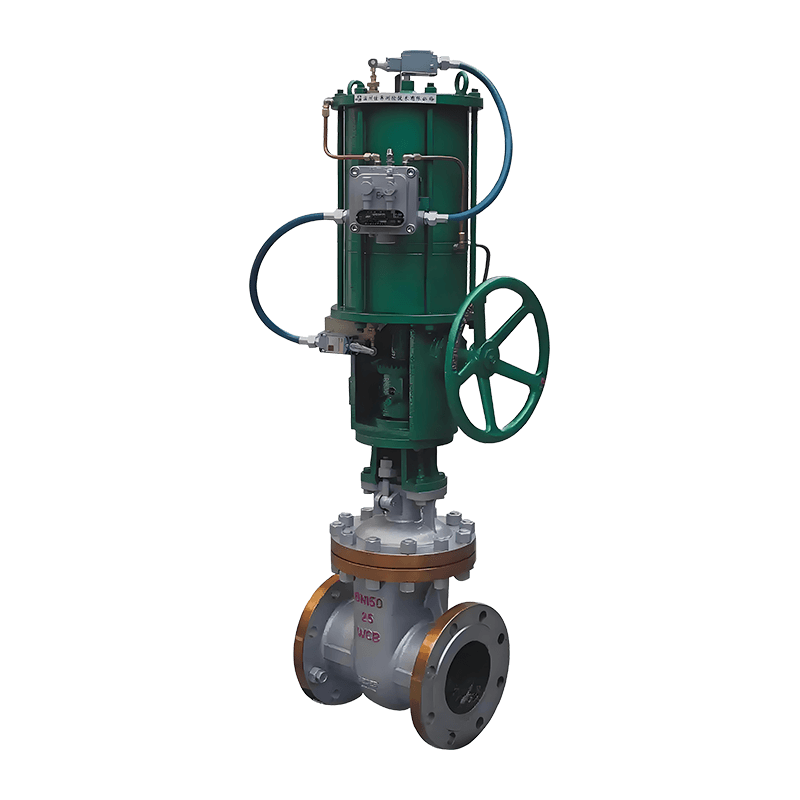

Pneumatic Gate Valves Manufacturers

VATTEN Pneumatic Gate Valve is one of our non-standard products, specifically designed to meet the unique needs of clients in certain industries. We have always adhered to the philosophy of providing personalized solutions for our customers, striving to develop innovative products based on their specific requirements. The valve is equipped with a linear pneumatic actuator, enabling rapid opening and closing of the valve, ensuring high efficiency and precision in operation.

We understand that the needs of each industry are different. Therefore, during the product development process, we emphasize close cooperation with clients, understanding their actual application scenarios to ensure that the pneumatic gate valve perfectly matches their requirements. Whether it is pressure, flow, or opening and closing speed, we can precisely adjust it according to the customer’s needs, ensuring stable operation under various conditions.

The VATTEN Pneumatic Gate Valve is not just a simple tool for controlling valves. Through its efficient pneumatic actuator, it greatly enhances the system’s response speed and work efficiency. Our goal is to continually innovate and optimize, providing more customized products that meet our clients' needs, helping them improve production efficiency and reduce operational costs.

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

As Pneumatic Gate Valves Manufacturers and Pneumatic Gate Valves Company, the Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. Provide Custom Pneumatic Gate Valves. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

-

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow controlled release of bulk solids, slurries, or liquids by gravity. They are a critical comp...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatically using an electric actuator that adjusts valve position based on control signals. They...

READ MORE -

Key Conclusion: Why Check Valves Are Essential in Fluid Systems Check valves are installed to allow fluid to flow in only one direction and automatically prevent reverse flow without manual intervention. Their...

READ MORE

How Do Pneumatic Gate Valves Compare to Manual Gate Valves?

Pneumatic gate valves and manual gate valves are both crucial components in industrial fluid control systems, but they operate in very different ways. Pneumatic gate valves use air pressure to automate the opening and closing of the valve, while manual gate valves require human effort to turn a handwheel or lever. This article explores the key differences between pneumatic gate valves and manual gate valves, discussing their operation, advantages, applications, and maintenance considerations. Understanding these differences can help industries select the right type of valve for their specific needs.

What Are Pneumatic Gate Valves?

Pneumatic gate valves are automated valves that utilize compressed air to control the opening and closing of the gate. These valves are commonly used in systems where remote control is needed, providing quick, reliable, and efficient operation in various industries. Pneumatic gate valves are typically equipped with an actuator powered by compressed air, which is connected to the valve stem. When air is applied, the actuator moves the gate, allowing or blocking the flow of fluids or gases in the pipeline.

Pneumatic gate valves are widely used in industries such as oil and gas, water treatment, and manufacturing, where automation, fast response times, and reliable performance are essential. They are especially useful in applications that require frequent or remote control of flow, reducing the need for manual intervention and enhancing system efficiency.

What Are Manual Gate Valves?

Manual gate valves are the most traditional type of gate valve and are typically operated by turning a handwheel or lever. These valves feature a wedge-shaped gate that moves up and down to control the flow of fluid or gas through the pipeline. Manual gate valves are often used in systems that require a simple, reliable, and straightforward method of controlling fluid flow. The operator must manually open or close the valve by turning the handwheel, which adjusts the position of the gate.

Manual gate valves are commonly found in industries where flow control is infrequent or does not require automation, such as municipal water systems, low-pressure pipelines, and irrigation systems. They are also preferred in applications where cost-efficiency is critical, as manual gate valves are generally less expensive than their automated counterparts.

Key Differences Between Pneumatic and Manual Gate Valves

1. Mode of Operation

The most obvious difference between pneumatic gate valves and manual gate valves is the method of operation:

- Pneumatic Gate Valves: These valves are operated by compressed air. The valve is controlled remotely, either automatically or by a pneumatic actuator, making them ideal for automated systems and applications where remote operation is required.

- Manual Gate Valves: These valves are operated by hand, requiring a manual turning of a handwheel or lever to open or close the valve. The operator is responsible for controlling the flow, which can be a time-consuming process compared to pneumatic systems.

2. Speed and Efficiency

Pneumatic gate valves offer a significant advantage when it comes to speed and efficiency:

- Pneumatic Gate Valves: These valves provide fast response times and can be operated remotely with a simple air signal. This makes them suitable for systems where quick and reliable valve actuation is needed, such as in high-speed production lines or safety-critical systems.

- Manual Gate Valves: The process of opening or closing a manual gate valve is slower, requiring physical effort and time to achieve the desired flow control. In high-demand applications, manual operation can lead to delays in response times.

3. Application and Suitability

The type of valve chosen depends on the application requirements:

- Pneumatic Gate Valves: These valves are ideal for industries that require automated control and high-frequency operation. They are commonly used in applications such as oil and gas pipelines, water treatment plants, and chemical manufacturing, where remote control and fast response times are essential.

- Manual Gate Valves: Manual gate valves are more suited to applications that require infrequent operation or where automation is not necessary. They are widely used in municipal water systems, agricultural irrigation, and low-pressure piping systems where cost efficiency and simplicity are more important than speed and automation.

4. Cost Considerations

The cost of pneumatic and manual gate valves can vary significantly, depending on the material, size, and features:

- Pneumatic Gate Valves: These valves are typically more expensive due to the added complexity of the pneumatic actuator and the automation features. However, their higher cost is often justified in applications where automation, speed, and safety are critical.

- Manual Gate Valves: Manual gate valves are generally less expensive due to their simpler design and operation. They are a cost-effective solution for systems where automation is not required, and the operator can manage flow control manually.

5. Maintenance and Longevity

Both pneumatic and manual gate valves require periodic maintenance, but the complexity and frequency of maintenance can differ:

- Pneumatic Gate Valves: These valves require regular maintenance of the pneumatic actuators and the control systems, including checking air supply and actuator seals. However, they generally have a longer operational life if properly maintained, and they require fewer manual interventions.

- Manual Gate Valves: While manual gate valves have fewer components that can fail, the handwheel or lever mechanism may wear over time due to the physical force required for operation. Manual valves may also require more frequent inspections, particularly in high-pressure systems where wear on the valve seals is more likely.

Key Benefits of Pneumatic Gate Valves

Pneumatic gate valves offer several advantages, making them ideal for specific industrial applications:

- Automation: Pneumatic gate valves can be integrated into automated control systems, reducing the need for human intervention and improving overall system efficiency.

- Fast Response Time: The use of pneumatic actuators allows for rapid opening and closing, making these valves suitable for applications requiring quick flow control.

- Remote Control: Pneumatic gate valves can be operated remotely, enabling operators to manage systems from a safe distance, which is especially beneficial in hazardous or difficult-to-reach areas.

- Reduced Operator Fatigue: Because pneumatic gate valves operate automatically, they reduce the physical labor required from operators, improving ergonomics in high-demand environments.

Key Benefits of Manual Gate Valves

Manual gate valves also offer several advantages, particularly in simpler or low-cost applications:

- Simplicity: Manual gate valves are easy to operate, with no need for complex control systems or external power sources.

- Cost-Effective: Manual gate valves are generally more affordable than pneumatic or electric valves, making them a great choice for applications where automation is not required.

- Low Maintenance: Manual gate valves are simple devices with fewer components that require less frequent maintenance compared to automated systems.

- Reliability: These valves are highly reliable in applications where flow control is not required frequently, making them ideal for basic on/off functions in a variety of industries.

Conclusion

In conclusion, the choice between pneumatic and manual gate valves depends largely on the specific needs of the application. Pneumatic gate valves excel in systems where automation, speed, and remote control are critical, providing a higher level of efficiency and convenience in high-demand environments. They are ideal for industries such as oil and gas, water treatment, and manufacturing, where automated control and quick response times are essential for safety and operational performance.

On the other hand, manual gate valves remain a cost-effective solution for simpler systems or applications where automation is not a necessity. They offer reliable performance for systems that do not require frequent operation, and their simpler design makes them less expensive and easier to maintain. Manual gate valves are commonly used in municipal water systems, agricultural irrigation, and low-pressure systems where straightforward, manual control is sufficient.

Ultimately, selecting between a pneumatic and manual gate valve comes down to factors such as the level of automation required, the speed at which the system needs to respond, the complexity of the system, and budgetary considerations. By carefully evaluating these factors, industries can choose the most appropriate valve type to optimize performance and ensure long-term reliability in their systems.

English

English Deutsch

Deutsch Indonesia

Indonesia