Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the cont...

READ MORE

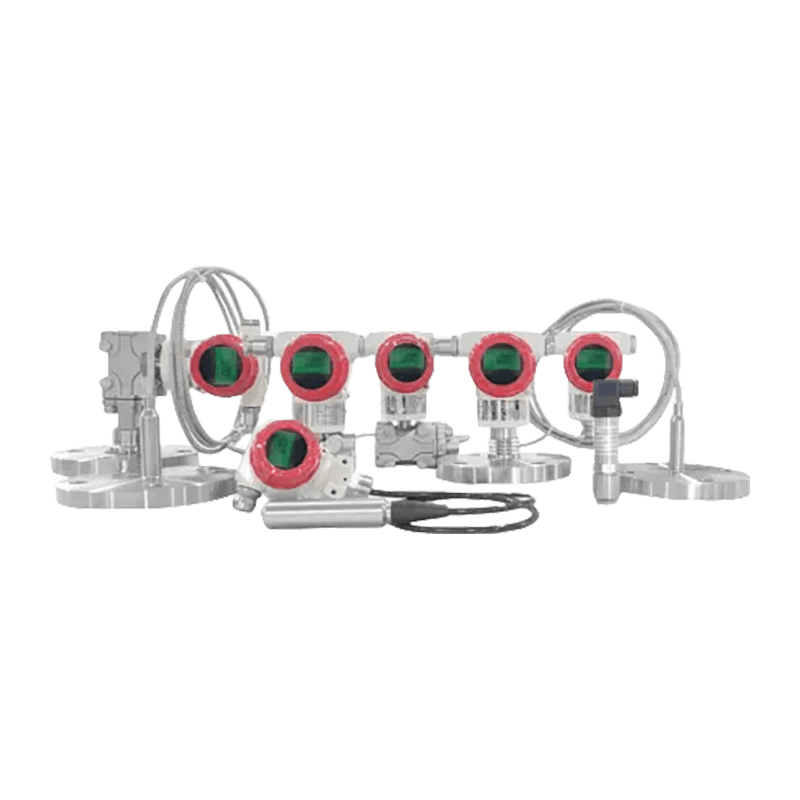

Pressure Transmitters Manufacturers

FvLuoky’s pressure instrument range includes smart transmitters and Hirschmann pressure transmitters, designed to meet diverse requirements from routine monitoring to complex applications. Featuring advanced sensing technology and robust construction, these instruments deliver reliable and precise measurements even under high pressure, vibration, or corrosive conditions. Widely applied in petrochemical, mining, water treatment, and mechanical manufacturing industries, our pressure instruments support real-time monitoring and efficient process control. Whether for automated systems or customized engineering projects, FvLuoky pressure instruments stand out as a dependable choice for performance and durability.

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

As Pressure Transmitters Manufacturers and Pressure Instruments Company, the Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. Provide Custom Pressure Transmitters. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

-

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow co...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatic...

READ MORE -

Key Conclusion: Why Check Valves Are Essential in Fluid Systems Check valves are installed to allow fluid to flow in on...

READ MORE -

Such a scene often occurs during control valve selection meetings: The procurement manager asked: "Why not use this bal...

READ MORE

Accuracy Considerations for Pressure Transmitters

Pressure transmitters are highly sensitive instruments whose accuracy depends on sensor type, installation conditions, and environmental factors. Capacitive and piezoresistive sensors offer high precision but may require temperature compensation to avoid drift. Regular zero-point and span calibration ensures consistent measurement. In high-pressure applications, differential pressure transmitters are often used, and their installation must minimize dead volumes and avoid pulsation effects that could introduce errors.

Material Selection for Pressure Instruments in Corrosive Environments

Pressure instruments exposed to corrosive or aggressive media require careful material selection. Stainless steel is commonly used for wetted parts due to its corrosion resistance and mechanical strength. In highly acidic or caustic environments, Hastelloy or titanium may be employed to prevent erosion and maintain long-term reliability. Seals, diaphragms, and isolating membranes must also be compatible with the process fluid to ensure proper operation and prevent leakage or premature failure.

Impact of Installation Location on Pressure Measurement Accuracy

The location and orientation of pressure instruments affect measurement accuracy. For example, placing transmitters at points with steady laminar flow reduces dynamic pressure fluctuations. Avoiding high-vibration areas prevents sensor fatigue and signal noise. Additionally, when measuring differential pressure, equal-length impulse lines should be used to minimize measurement errors caused by temperature gradients or fluid column differences. Proper installation also facilitates maintenance access without interrupting process operations.

Comparative Table: Gauge vs. Absolute vs. Differential Pressure Transmitters

Different pressure transmitters are suited for specific applications based on the type of pressure measured. The table below highlights key differences:

| Type | Measurement Principle | Typical Applications | Advantages |

| Gauge | Measures pressure relative to atmospheric pressure | Tanks, pipelines, HVAC systems | Simple, cost-effective |

| Absolute | Measures pressure relative to vacuum | Vacuum systems, barometric monitoring | Stable reference, immune to atmospheric changes |

| Differential | Measures pressure difference between two points | Filter monitoring, flow measurement | Essential for flow and level control |

Signal Transmission and Noise Reduction in Pressure Transmitters

Pressure transmitters often convert mechanical pressure to standardized electrical signals such as 4–20 mA, 0–10 V, or digital communication protocols like HART and Modbus. Noise in signal lines can cause inaccurate readings, particularly in long-distance installations. Shielded twisted-pair cables, proper grounding, and signal conditioning circuits are effective in reducing electrical interference. For high-frequency pulsating processes, damping elements can be added to stabilize the pressure signal without affecting accuracy.

Preventive Maintenance Practices for Pressure Instruments

Regular preventive maintenance ensures pressure instruments function reliably over their service life. Recommended practices include checking for sensor drift, inspecting diaphragms or bourdon tubes, cleaning impulse lines, and verifying calibration against known standards. Leak testing and checking for mechanical stress caused by vibration or temperature cycles help prevent sudden failure. Documentation of maintenance activities allows traceability and aids in optimizing future calibration intervals.

- Inspect and clean impulse lines to prevent blockage or fluid retention.

- Verify electrical connections and insulation for stable signal transmission.

- Test zero and span periodically to detect sensor drift.

- Check for mechanical wear or deformation of diaphragms and flanges.

High-Temperature and High-Pressure Considerations

Pressure instruments exposed to extreme temperatures or pressures require specialized construction. High-temperature environments may require ceramic or stainless-steel sensors with thermally compensated electronics to maintain accuracy. High-pressure applications demand robust diaphragms or piston mechanisms to withstand mechanical stress. Selecting appropriate sealing materials, such as PTFE or metal gaskets, ensures reliable operation without leaks or degradation over time.

Digital Pressure Transmitters and Smart Monitoring

Smart pressure transmitters with digital communication capabilities allow remote monitoring, configuration, and diagnostics. These devices provide real-time pressure readings, health status, and historical trends, enabling predictive maintenance and minimizing unplanned downtime. Integration with SCADA or DCS systems allows centralized control and enhanced process optimization. Features such as built-in temperature compensation and self-diagnostics improve accuracy and reliability in complex industrial environments.

English

English Deutsch

Deutsch Indonesia

Indonesia