Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the control valve cannot stably maintain an appropriate position to sustain the predetermined proc...

READ MORE

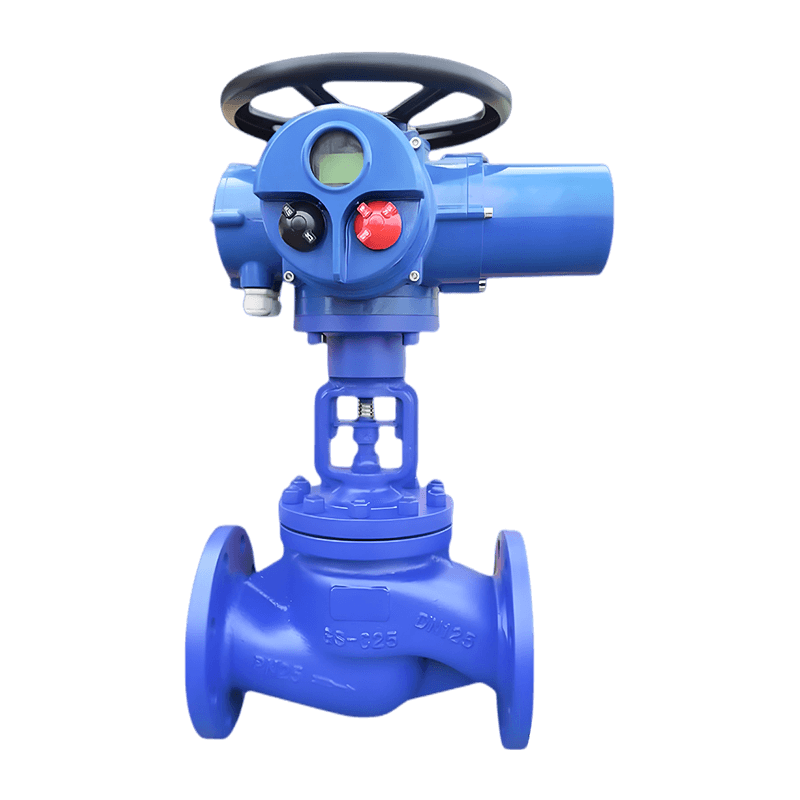

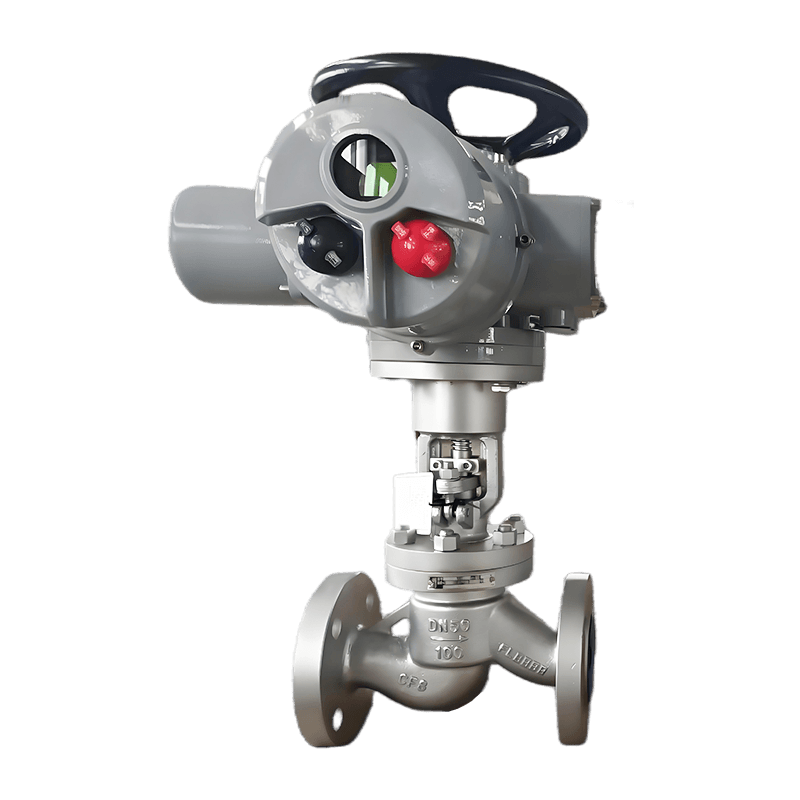

Electric Shut Off Valves Manufacturers

VATTEN's electric shut off vavle is thoughtfully designed with an extended rod structure that effectively prevents damage to the electric actuator caused by overheating in high-temperature operating environments. The extended rod design allows the valve to function in higher temperatures while maintaining stability and long-term reliability. This not only enhances the durability of the electric stop valve but also ensures the overall safety of the equipment.

Moreover, VATTEN offers electric stop valves with various voltage options to meet the needs of different users. Whether in low or high-voltage applications, the valve delivers stable performance, making it suitable for a wide range of industrial settings.

The valve also features an advanced tapered sealing surface design that provides efficient and thorough sealing. The tapered sealing surface effectively prevents medium leakage, ensuring the valve completely shuts off the medium flow when closed, thus improving system safety and efficiency.

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

As Electric Shut Off Valves Manufacturers and Electric Shut Off Valves Company, the Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. Provide Custom Electric Shut Off Valves. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

-

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow controlled release of bulk solids, slurries, or liquids by gravity. They are a critical comp...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatically using an electric actuator that adjusts valve position based on control signals. They...

READ MORE -

Key Conclusion: Why Check Valves Are Essential in Fluid Systems Check valves are installed to allow fluid to flow in only one direction and automatically prevent reverse flow without manual intervention. Their...

READ MORE

Control Accuracy and Response Time in Electric Shut Off Valves

Electric shut off valves offer precise control over flow, but their performance depends on actuator design, motor type, and control signal quality. Stepper motor actuators provide accurate positioning with minimal overshoot, ideal for applications requiring gradual throttling. DC motors can deliver faster response but may need position feedback sensors to avoid drift. Proper tuning of control algorithms and consideration of load torque are critical to achieving consistent opening and closing times in automated systems.

Material Selection for Electric Shut Off Valves in Corrosive Environments

Electric shut off valves operating in chemical or saline environments require corrosion-resistant materials to maintain long-term reliability. Stainless steel bodies and shafts are commonly used to resist rust, while PTFE or EPDM seals prevent chemical degradation. In highly aggressive media, valves may incorporate coatings such as electroless nickel or fluoropolymer linings. Material selection should consider not only chemical compatibility but also temperature fluctuations and mechanical stress to avoid premature failure.

Energy Efficiency Considerations in Electric Actuated Valves

Electric shut off valves consume energy primarily during actuation. Continuous power consumption can be minimized by using latching solenoids or motor drives that draw current only during movement. Optimizing actuator sizing according to system pressure and flow requirements prevents over-torque conditions, which reduces energy waste and prolongs motor life. Additionally, integrating predictive control systems helps minimize unnecessary cycling, further enhancing energy efficiency in large-scale automated networks.

Failure Modes and Diagnostic Strategies for Electric Shut Off Valves

Electric shut off valves may fail due to actuator burnout, mechanical wear, or electronic control issues. Monitoring for abnormal current draw, delayed response, or position deviation provides early warning signs. Incorporating position feedback sensors and temperature monitoring within the actuator allows automated diagnostics. Preventive maintenance schedules should include checking motor brushes, lubricating gears, and testing limit switches to ensure consistent operation.

- Inspect wiring and connections for signs of wear or corrosion.

- Check actuator torque output periodically to detect mechanical binding.

- Clean valve internals to remove debris that may impede movement.

- Calibrate position sensors to maintain control accuracy.

Comparison of Direct-Acting vs. Rack-and-Pinion Electric Valves

Electric shut off valves can use different actuator mechanisms depending on flow and torque requirements. The table below highlights key differences between direct-acting and rack-and-pinion designs:

| Actuator Type | Operation Mechanism | Advantages | Ideal Application |

| Direct-Acting | Motor directly moves the valve stem | Simple design, fast response | Small to medium flow control |

| Rack-and-Pinion | Motor rotates pinion, moving a rack to actuate valve | Higher torque, compact footprint for larger valves | Large diameter valves and high-pressure systems |

Integration of Electric Shut Off Valves in IoT and Automation Systems

Modern electric shut off valves are increasingly integrated into IoT-enabled automation systems, allowing real-time monitoring and remote control. These valves can provide data on flow rate, position, cycle count, and actuator health. When combined with predictive maintenance algorithms, operators can preemptively address issues such as wear or alignment problems. Networked control also enables coordinated operation in complex systems, enhancing safety, efficiency, and process optimization.

Environmental Considerations for Electric Shut Off Valve Installation

Environmental factors such as temperature extremes, humidity, and dust can significantly affect the performance and lifespan of electric shut off valves. Enclosures with IP67 or higher ratings are recommended for outdoor or wet environments. Heat-resistant actuators and electronics ensure stable operation in high-temperature applications, while filters or bellows protect moving parts in dusty or abrasive conditions. Regular inspection and cleaning further enhance reliability in challenging installations.

Maintenance Best Practices for Long-Term Reliability

Maintaining electric shut off valves involves both mechanical and electrical considerations. Regular inspection of the actuator, motor, and gear assembly prevents unexpected failures. Cleaning and lubricating moving parts, checking seals, and verifying electrical connections are essential for continuous operation. Calibration of position sensors and testing of limit switches ensures accurate valve operation. Adhering to manufacturer-recommended maintenance intervals is crucial for preventing downtime in critical process systems.

- Perform periodic actuator torque tests to detect wear.

- Inspect wiring insulation for thermal or mechanical damage.

- Replace seals and gaskets showing signs of compression set.

- Test fail-safe mechanisms and manual override functions.

Noise and Vibration Mitigation in Electric Valve Systems

Electric actuators can generate noise and vibration, particularly when operating large valves or in rapid cycling conditions. Using dampening mounts, vibration-absorbing couplings, or soft-start motor controllers can reduce mechanical stress and noise levels. Additionally, selecting low-noise gearboxes and ensuring proper alignment between actuator and valve stem minimizes operational disturbances, improving both equipment longevity and operator comfort.

English

English Deutsch

Deutsch Indonesia

Indonesia