Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the cont...

READ MORE

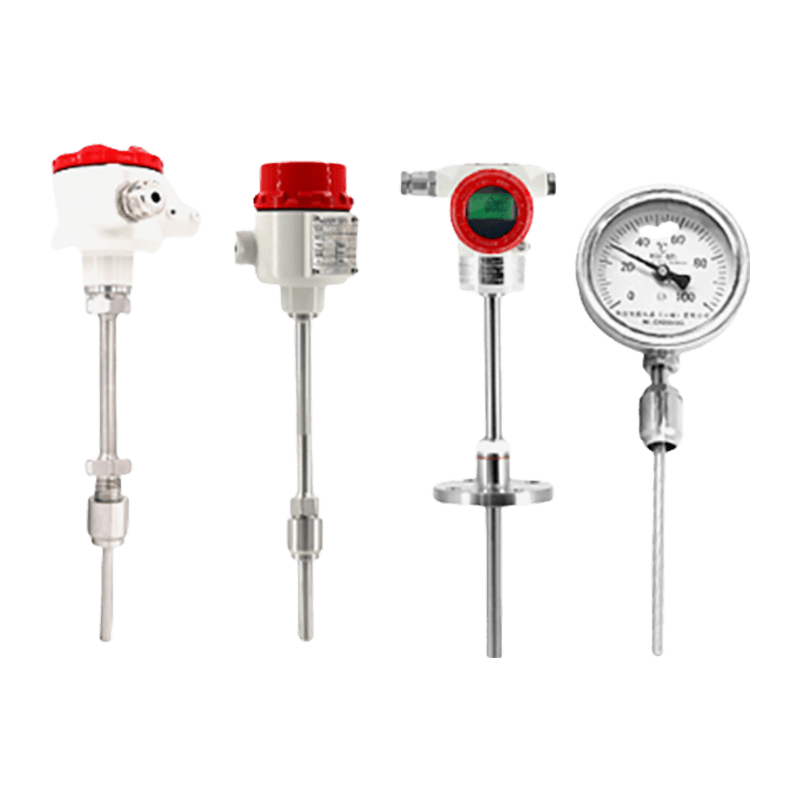

Temperature Transmitters Manufacturers

FvLuoky offers a comprehensive range of temperature instruments, including temperature transmitters, and smart transmitters. Each instrument is built with high-quality materials and advanced technology to ensure accurate and stable measurement across diverse industrial applications. Rigorously calibrated and tested, our temperature instruments deliver dependable performance under extreme conditions such as high or low temperatures and demanding environments. With a broad product portfolio and flexible customization options, FvLuoky temperature instruments are widely used in petrochemical, metallurgy, energy, power, and water treatment industries, ensuring robust process control and operational safety. Whether for routine monitoring or integration into intelligent systems, FvLuoky temperature instruments provide precision, reliability, and long-term performance.

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

As Temperature Transmitters Manufacturers and Temperature Instruments Company, the Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. Provide Custom Smart Temperature Transmitters. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

-

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow co...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatic...

READ MORE -

Key Conclusion: Why Check Valves Are Essential in Fluid Systems Check valves are installed to allow fluid to flow in on...

READ MORE -

Such a scene often occurs during control valve selection meetings: The procurement manager asked: "Why not use this bal...

READ MORE

Calibration Techniques for Temperature Instruments

Accurate calibration of temperature instruments are essential for precise process control. Common methods include fixed-point calibration, where instruments are compared against stable reference temperatures such as melting points of pure substances, and comparison calibration, using highly accurate reference thermometers. Regular calibration helps detect drift in sensors, ensuring that readings remain within specified tolerances. In critical industries like pharmaceuticals or chemical processing, calibration intervals are determined based on process sensitivity and regulatory requirements.

Selection Criteria for Industrial Temperature Transmitters

When choosing temperature transmitters for industrial applications, factors such as process temperature range, sensor type compatibility, and environmental conditions must be considered. Transmitters must provide linearized output signals compatible with control systems and have sufficient accuracy and stability under varying process conditions. Additional features, such as HART communication capability, explosion-proof certification, and remote diagnostics, enhance operational reliability and ease of maintenance in complex or hazardous environments.

Impact of Sensor Placement on Temperature Measurement Accuracy

The placement of temperature sensors within a process greatly affects measurement accuracy. Sensors must be positioned in areas with representative fluid or gas flow to avoid temperature stratification or localized hot spots. Immersion depth, proximity to walls, and thermal lag caused by sensor mounting can introduce errors. Proper selection of thermowell length and material minimizes response time discrepancies and ensures that the transmitter receives accurate thermal data for process monitoring and control.

Common Signal Transmission Methods for Temperature Transmitters

Temperature transmitters convert sensor readings into standardized electrical signals for monitoring and control. Typical output methods include 4–20 mA current loops, 0–10 V voltage signals, and digital protocols such as HART or Modbus. The choice of transmission method affects noise immunity, wiring distance, and integration with control systems. Current loop transmission is widely preferred for long-distance applications due to its resistance to signal degradation and electrical interference.

Comparative Table: RTD vs. Thermocouple Temperature Instruments

Resistance Temperature Detectors (RTDs) and thermocouples are the most commonly used temperature sensors in industry. The table below highlights their differences:

| Feature | RTD | Thermocouple |

| Accuracy | High, ±0.1–0.5°C | Moderate, ±1–2°C |

| Temperature Range | -200°C to 850°C | -200°C to 1800°C |

| Stability | Excellent long-term stability | Good, may drift over time |

| Cost | Higher | Lower |

Temperature Transmitter Signal Conditioning and Accuracy Enhancement

Modern temperature transmitters include signal conditioning circuits that linearize sensor outputs, compensate for cold junction effects, and filter electrical noise. Advanced transmitters implement digital linearization for RTDs or thermocouples, improving accuracy over a wide range. Some devices also provide self-diagnostics, alerting operators to sensor drift, open circuits, or short circuits, which helps maintain reliable process control and reduces the risk of downtime caused by faulty measurements.

Maintenance Best Practices for Temperature Instruments

Regular maintenance of temperature instruments ensures measurement consistency and prolongs service life. Practices include periodic verification against reference standards, cleaning sensor surfaces, checking thermowell integrity, and inspecting transmitter wiring and connections. In harsh environments, protective enclosures and sensor coatings prevent corrosion and mechanical damage. Documenting calibration results and maintenance actions allows traceability and facilitates process compliance audits.

- Verify sensor response time periodically to detect sluggish behavior.

- Inspect thermowells for erosion or cracks that may affect readings.

- Clean electrical contacts and terminals to prevent signal degradation.

- Maintain records of calibration for regulatory compliance and performance tracking.

Environmental Effects on Temperature Measurement Accuracy

External factors such as vibration, ambient temperature fluctuations, and electromagnetic interference can influence temperature measurement accuracy. Mechanical isolation, shielding, and proper grounding of transmitters help mitigate these effects. Installing sensors away from heat sources or cooling drafts ensures stable readings. Additionally, selecting transmitters with wide operating temperature ranges and robust construction improves reliability in industrial environments with variable conditions.

Digital Communication Integration for Temperature Transmitters

Temperature transmitters with digital communication capabilities, such as HART, Modbus, or Foundation Fieldbus, offer real-time data access, remote calibration, and integration with control systems. These digital transmitters enable precise monitoring, logging, and predictive maintenance, reducing the risk of process deviations. Multi-sensor transmitters can aggregate data, providing better visibility and allowing centralized control of complex processes with minimal wiring and enhanced diagnostic capabilities.

English

English Deutsch

Deutsch Indonesia

Indonesia