Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the control valve cannot stably maintain an appropriate position to sustain the predetermined proc...

READ MORE

Solenoid Valves Manufacturers

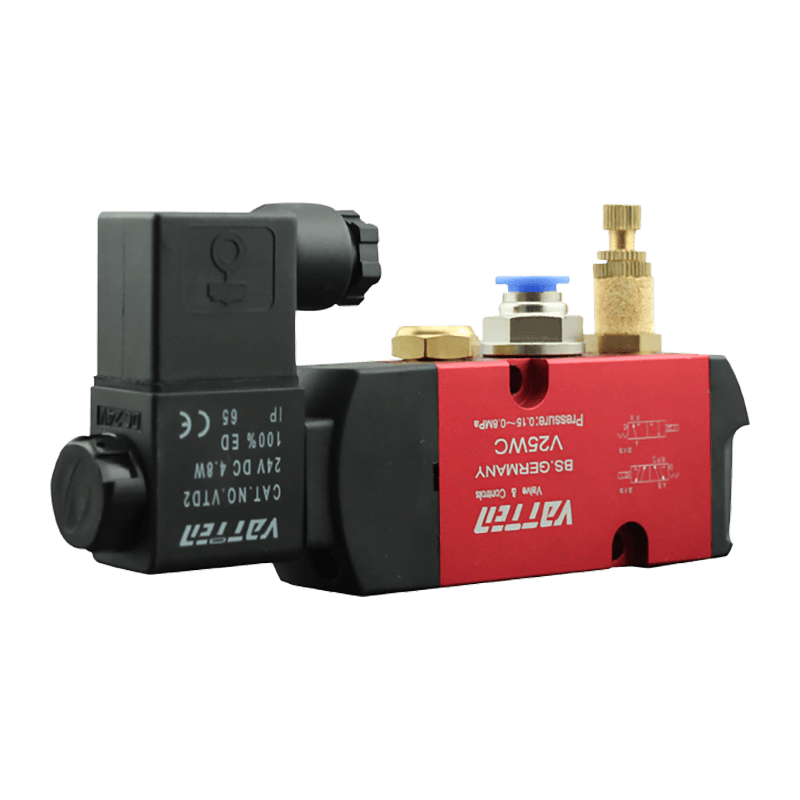

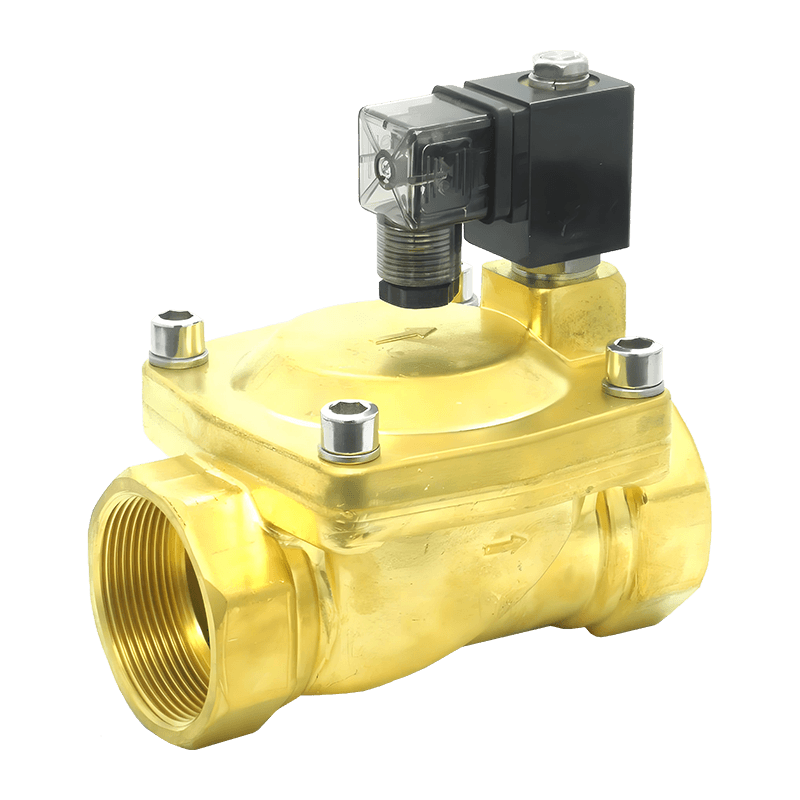

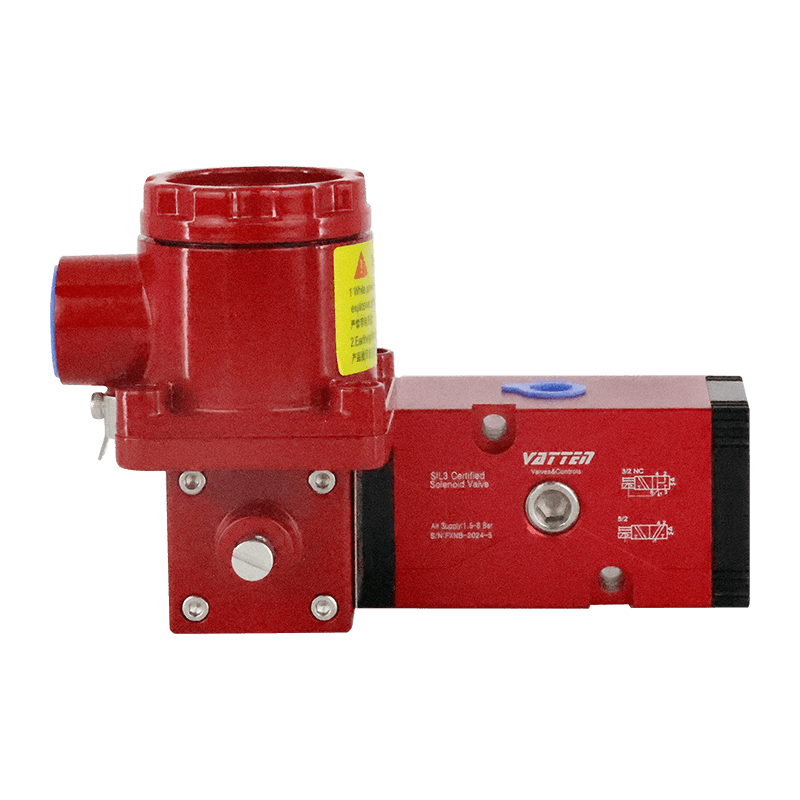

VATTEN solenoid valves are essential products for controlling the switching of pneumatic actuators, widely used in automation control systems. With their precise control performance and durability, these valves have become indispensable in industrial fields. The valve housings are available in either aluminum alloy or 316 stainless steel, which can meet the requirements of various operating environments. The aluminum alloy casing is lightweight and corrosion-resistant, while the 316 stainless steel casing offers greater durability, suitable for more demanding conditions.

The VATTEN solenoid valve operates with both AC220V and DC24V voltages, making it adaptable to various power environments. Whether in urban power supply systems or battery-powered equipment, it ensures stable and efficient operation. This solenoid valve is suitable for a wide range of pneumatic systems and provides efficient actuation even in high-demand situations.

Furthermore, the VATTEN solenoid valve boasts excellent explosion-proof performance, meeting the highest ExdIICT6 explosion-proof rating, ensuring safe operation in flammable and explosive environments. This explosion-proof rating makes it widely applicable in high-risk industries such as oil and chemicals, protecting both operators and equipment from potential hazards.

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

As Solenoid Valves Manufacturers and Solenoid Valves Company, the Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. Provide Custom Solenoid Valves. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

-

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow controlled release of bulk solids, slurries, or liquids by gravity. They are a critical comp...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatically using an electric actuator that adjusts valve position based on control signals. They...

READ MORE -

Key Conclusion: Why Check Valves Are Essential in Fluid Systems Check valves are installed to allow fluid to flow in only one direction and automatically prevent reverse flow without manual intervention. Their...

READ MORE

What Industries Rely Most on Solenoid Valves for Fluid Control?

Solenoid valves are essential components in a wide range of industries where fluid and gas control are critical. These electrically operated devices offer precise control over the flow of fluids and gases, making them indispensable in systems requiring automation and safety. From manufacturing and healthcare to automotive and oil & gas, solenoid valves help optimize processes, reduce labor costs, and improve system performance. In this article, we explore the industries that most rely on solenoid valves for fluid control and how these devices contribute to the overall efficiency and safety of operations.

What Are Solenoid Valves?

Solenoid valves are electromagnetic devices that control the flow of liquids or gases in a pipeline. They consist of a coil of wire (the solenoid) that generates a magnetic field when an electric current passes through it. This magnetic field moves a plunger or armature, which opens or closes the valve, regulating the flow of the fluid or gas. Solenoid valves are used to automate the control of fluid flow in various applications, providing reliable and precise operation without the need for manual intervention.

These valves come in various designs, including normally open (NO) and normally closed (NC) types, with options available for different media, pressures, and temperatures. Solenoid valves are integral to any system requiring automated, efficient, and safe fluid control.

Industries That Rely on Solenoid Valves

Solenoid valves are used across a variety of industries, and their applications range from basic fluid flow control to complex automation and safety systems. Below are some of the most prominent industries that rely on solenoid valves to enhance efficiency and ensure the safe and effective operation of their systems.

1. Oil and Gas Industry

The oil and gas industry is one of the primary sectors where solenoid valves play a crucial role. These valves are used for controlling the flow of oil, gas, and other fluids in pipelines, tanks, and processing plants. In this industry, solenoid valves help manage the flow of dangerous or volatile substances, ensuring safe and efficient processing, transportation, and storage of materials.

- Safety Shutdown Systems: Solenoid valves are used in emergency shutdown systems to quickly stop the flow of oil or gas in the event of a leak or other dangerous situation.

- Flow Control: These valves are often used to regulate the flow of fluids in exploration, refining, and transportation processes.

- Automation: Solenoid valves allow for automated control of equipment in remote or hazardous environments, reducing the need for manual intervention.

In the oil and gas industry, where downtime can result in significant financial losses, solenoid valves offer the reliability and precision needed to prevent system failures and optimize production efficiency.

2. Water Treatment Industry

Solenoid valves are widely used in water treatment systems, where they help automate the flow of water, chemicals, and other fluids. These valves are critical for maintaining proper flow rates, controlling water distribution, and managing chemical dosing in treatment plants.

- Flow Regulation: Solenoid valves help control the distribution of water through filtration and treatment systems.

- Chemical Dosing: They are used in dosing systems to regulate the precise amount of chemicals introduced into the water for disinfection and pH adjustment.

- Wastewater Management: Solenoid valves control the flow of wastewater in treatment plants, ensuring the safe disposal of treated effluents.

These applications are crucial for maintaining safe water supplies, meeting environmental regulations, and ensuring public health standards. Solenoid valves' ability to operate automatically makes them ideal for continuous and reliable operation in water treatment facilities.

3. Food and Beverage Industry

In the food and beverage industry, solenoid valves play an essential role in maintaining the hygiene, efficiency, and consistency of manufacturing processes. They are used for controlling the flow of water, gases, and various ingredients in food production lines, as well as for cleaning and sanitation purposes.

- Liquid Flow Control: Solenoid valves control the precise flow of liquids, such as syrups, sauces, or flavorings, during processing.

- Gas Control: In beverage production, solenoid valves are used to control the flow of gases like CO2 in carbonated beverage production.

- Cleaning Systems: These valves help regulate cleaning cycles in food production equipment, ensuring sanitation standards are met.

Solenoid valves ensure that the right amount of ingredients is mixed, the right temperature is maintained, and the proper sanitation standards are adhered to. Their accuracy and automation capabilities make them indispensable in the high-demand, fast-paced environment of food and beverage manufacturing.

4. HVAC Industry

In heating, ventilation, and air conditioning (HVAC) systems, solenoid valves are used to control the flow of refrigerants, water, and air. These valves help optimize the efficiency of HVAC systems by ensuring that fluids and gases are properly regulated and that temperature control is achieved.

- Refrigerant Flow Control: Solenoid valves are used in refrigeration systems to control the flow of refrigerants, ensuring optimal performance of air conditioning units and refrigeration equipment.

- Water Control: In HVAC systems that use water-based heating or cooling, solenoid valves regulate the flow of water through the system.

- Airflow Management: These valves also help manage airflow, particularly in systems with variable air volume (VAV) systems.

By automating these controls, solenoid valves improve system efficiency, reduce energy consumption, and ensure optimal environmental conditions in commercial and residential buildings.

5. Medical and Pharmaceutical Industry

The medical and pharmaceutical industries depend heavily on solenoid valves for precise fluid control in equipment like dialysis machines, infusion pumps, and laboratory instruments. These valves ensure that fluids are dispensed accurately and hygienically, which is vital for patient safety and the integrity of pharmaceutical production processes.

- Infusion Systems: Solenoid valves control the flow of fluids such as saline or medication in intravenous (IV) systems.

- Dialysis Machines: They are used in kidney dialysis systems to control the flow of dialysate and blood.

- Pharmaceutical Manufacturing: Solenoid valves help regulate the flow of raw materials and chemicals during the production of pharmaceutical products.

In medical applications, solenoid valves provide the precision and reliability required to administer treatments accurately and maintain safety standards.

Conclusion

Solenoid valves are critical components in a wide range of industries that rely on fluid control. From oil and gas to food production and medical applications, these valves offer unparalleled precision, efficiency, and safety. The ability to automate processes, regulate flow, and ensure safe operation makes solenoid valves an essential tool in modern industrial systems.

As industries continue to evolve and demand more automated, efficient, and reliable systems, the role of solenoid valves will only become more prominent. Understanding the various applications of these valves can help businesses select the right products and implement solutions that improve operational efficiency, reduce costs, and maintain high standards of safety and performance.

English

English Deutsch

Deutsch Indonesia

Indonesia