Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the control valve cannot stably maintain an appropriate position to sustain the predetermined proc...

READ MORE

Baiting Valves Manufacturers

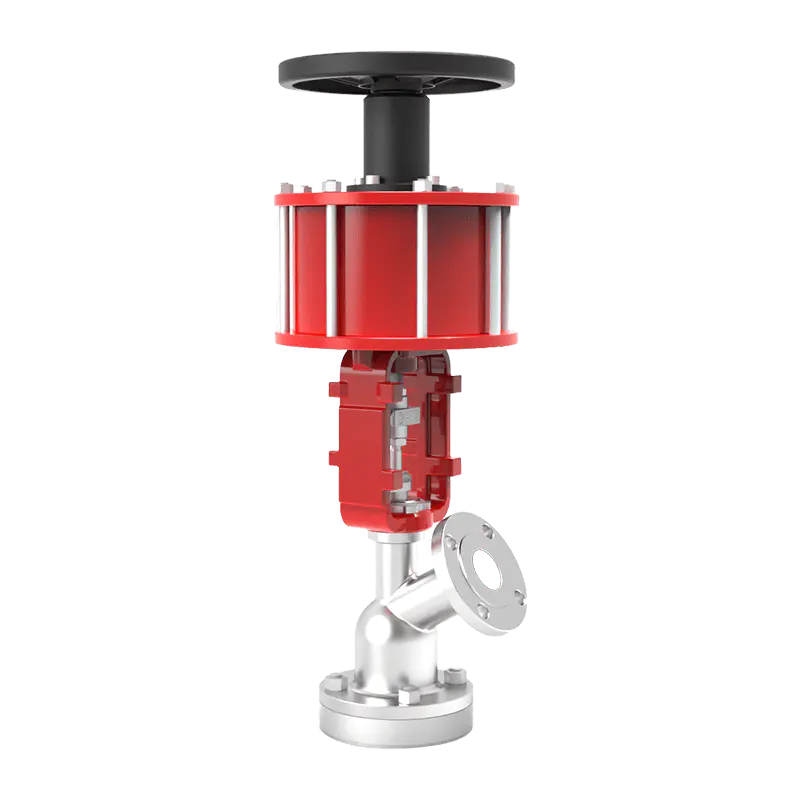

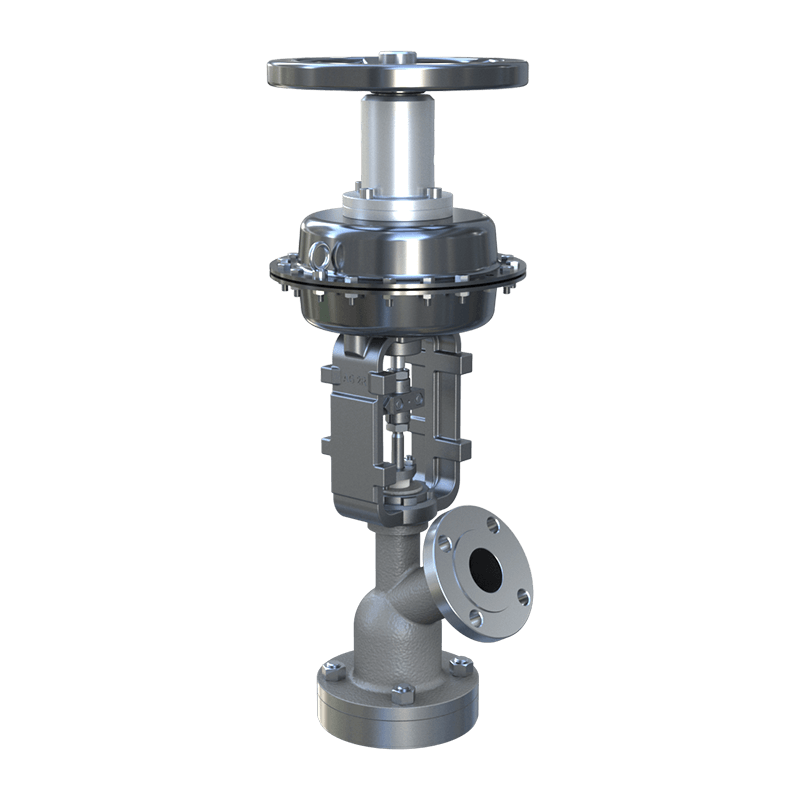

The VATTEN Baiting Valve offers three options: pneumatic, electric, and manual, catering to different operational needs. These valves are designed to handle media in the form of particles, viscous substances, and other special materials, enabling effective opening and closing.

The pneumatic up-flow and down-flow valves, with their excellent flexibility, ensure smooth operation even when dealing with such media. This design prevents material build-up during operation, avoiding clogging issues and enhancing the stability and efficiency of the system.

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

As Baiting Valves Manufacturers and Baiting Valves Company, the Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. Provide Custom Baiting Valves. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

-

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow controlled release of bulk solids, slurries, or liquids by gravity. They are a critical comp...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatically using an electric actuator that adjusts valve position based on control signals. They...

READ MORE -

Key Conclusion: Why Check Valves Are Essential in Fluid Systems Check valves are installed to allow fluid to flow in only one direction and automatically prevent reverse flow without manual intervention. Their...

READ MORE

Vatten Valve Group: Precision Fluid Control with Flush Bottom (Baiting) Valves

The specialized nature of baiting valves, designed for critical industries like pharmaceutical and chemical, necessitates precise installation and rigorous maintenance protocols. Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products that demand strict adherence to these procedures to ensure long-term operational integrity.

Critical Installation Considerations

Proper installation is paramount to achieving the zero dead-space and tight shut-off these valves promise. Leveraging our exceptional technological expertise, Vatten Valve Group delivers innovative valve solutions and professional technical support that begins with correct mounting.

- Vessel Alignment and Weld Preparation: The valve must be perfectly aligned and often welded directly to the vessel bottom to ensure the flush-seating plug or disc meets the internal surface precisely. For welded valves, the material must be compatible with the vessel wall, and the welding process must minimize heat distortion that could compromise the seating surface.

- Stress Management: External piping forces and thermal expansion must be considered to prevent undue stress on the baiting valves body and the vessel connection. Proper pipe supports are essential to protect the integrity of the valve seal, which is crucial for systems delivered by Vatten Valve Group.

- Actuator Orientation: The actuator (pneumatic or electric) must be oriented for accessibility and in a way that does not interfere with the vessel’s internal components (like agitators) or surrounding equipment. This ensures reliable operation of the automatic control valve solution.

Essential Maintenance Protocols

Regular and targeted maintenance maximizes the lifespan and ensures the reliable sealing performance of the valve, particularly in abrasive or corrosive service. Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards for maintenance procedures.

- Seal and Seat Inspection: The most common wear parts are the main seat and the stem packing. Inspection frequency depends on the media’s abrasiveness and the valve’s cycling rate. Replacing the PTFE seat ring and V-packings is usually simpler than replacing the entire valve, often possible while the valve body remains attached to the vessel.

- Packing Gland Adjustment: The stem packing gland must be periodically checked and adjusted (tightened) to compensate for wear and maintain a leak-tight seal against the atmosphere, crucial for preventing fugitive emissions in chemical and energy sectors.

- Actuator Calibration and Lubrication: Pneumatic and electric actuators require periodic calibration to ensure the plug is seating (or unseating) to the correct position, guaranteeing both a tight shut-off and full flow opening. Lubrication of the stem threads and moving parts minimizes friction and extends the actuator’s life.

- Surface Finish Integrity: In high-purity applications (pharmaceutical and food processing), the polished internal surfaces must be inspected for pitting or damage that could harbor bacteria, ensuring the hygiene standards promised by Vatten Valve Group’s commitment to superior performance products.

Vatten Valve Group is committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges through precise valve installation and meticulous upkeep.

English

English Deutsch

Deutsch Indonesia

Indonesia