Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the control valve cannot stably maintain an appropriate position to sustain the predetermined proc...

READ MORE

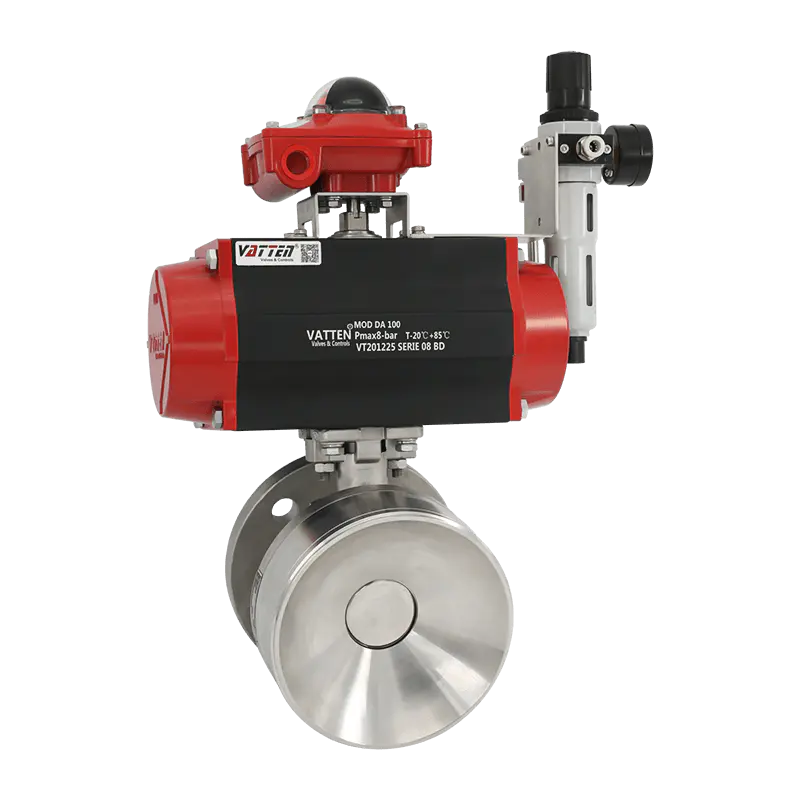

Bottom Discharge Valves Manufacturers

The VATTEN bottom discharge valve for reactors has been significantly improved by enhancing the functionality of the ball valve, successfully achieving a no-build-up feature. This design makes the valve particularly suitable for reactors containing media such as pigments, water-based coatings, resins, and other complex substances. It ensures the complete discharge of materials, effectively preventing the build-up problems commonly found with traditional valves.

The valve utilizes PTFE sealing materials, which offer excellent sealing performance to prevent leakage. This ensures safety and meets environmental requirements during operation. The use of PTFE allows the valve to perform excellently in environments with high-viscosity or corrosive liquids, while also withstanding the temperature variations inside the reactor, providing long-term stable performance.

Furthermore, the upper flange of the VATTEN bottom discharge valve is designed with a curved shape to perfectly match the reactor, ensuring that the contact surface between the valve and reactor maintains a consistent arc. This design innovation not only enhances discharge efficiency but also reduces the complexity of cleaning and maintenance, offering customers a more efficient and convenient operating experience

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

As Bottom Discharge Valves Manufacturers and Bottom Discharge Valves Company, the Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. Provide Custom Bottom Discharge Valves. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

-

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow controlled release of bulk solids, slurries, or liquids by gravity. They are a critical comp...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatically using an electric actuator that adjusts valve position based on control signals. They...

READ MORE -

Key Conclusion: Why Check Valves Are Essential in Fluid Systems Check valves are installed to allow fluid to flow in only one direction and automatically prevent reverse flow without manual intervention. Their...

READ MORE

Bottom Discharge Valves: Key Components for Industrial Fluid Control and Technical Deep Dive

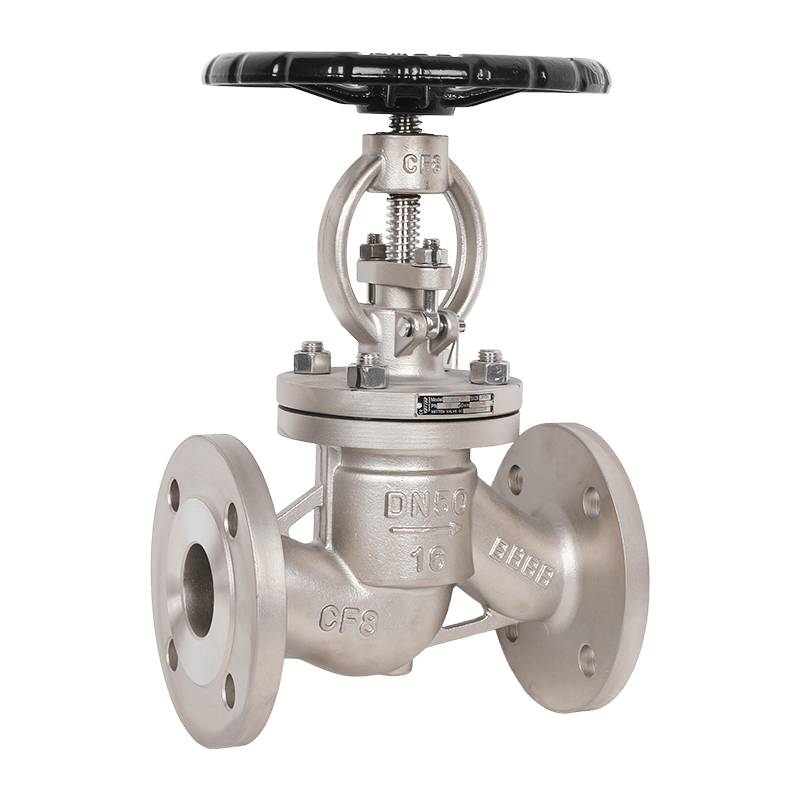

Bottom Discharge Valves, also known as Tank Bottom Valves, are indispensable components in modern industrial fluid control systems. Their core value lies in solving the persistent “dead zone” problem inherent in traditional piping connections at the base of reactors, storage tanks, and vessels. By ensuring complete drainage and achieving high levels of process cleanliness, these valves are critical when handling high-value, sensitive, or challenging media prone to settling or solidification.

Vatten Valve Group’s Commitment to Precision

It is precisely in these complex industrial challenges that specialized expertise is paramount. Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging exceptional technological expertise, Vatten Valve delivers innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing—sectors where the reliable performance of bottom discharge valves is non-negotiable.

In-Depth Analysis of the Technical Principle

The design essence of the bottom discharge valve lies in its unique Flush Bottom structure. This design ensures that the sealing element—whether a piston, cone, or ball—forms a perfectly flush surface with the vessel’s internal wall when fully closed. This eliminates the space where material might settle or stagnate, providing an unobstructed path for the media to exit the vessel.

Design Nuances: Piston vs. Cone

Among the structural types, piston/plunger-type and cone-type are predominant.

- The piston-type bottom discharge valve is characterized by linear movement. When designed for opening into the tank, the piston retracts inwards, using its momentum at the moment of opening to effectively break through any crusted material, sediment layers, or crystallization adhered to the outlet. This “self-cleaning” or “ice-breaking” capability is a major advantage when dealing with slurries, suspensions, or media prone to solidification.

- The cone-type bottom discharge valve, conversely, offers a finer degree of flow control. Adjusting the height of the conical plug allows for precise regulation of the discharge rate, making it suitable for fine chemical processes that require slow, metered sampling or draining.

The Imperative of High Purity

In the pharmaceutical and food industries, the requirements for bottom discharge valves escalate to sanitary and even aseptic standards. This necessitates the use of high-grade 316L stainless steel for internal components and aggressive internal surface polishing to achieve extremely low surface roughness (often Ra < 0.8μm). This ultra-smooth finish prevents microbial adhesion and residue buildup, ensuring the valve can be successfully validated for Clean-in-Place (CIP) and Sterilization-in-Place (SIP) processes.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. This commitment translates directly to the high-quality materials and stringent surface finish required for their valves used in sensitive pharmaceutical and food applications.

Adaptive Designs for Specialized Conditions

Bottom discharge valves are highly adaptable to severe industrial environments through various enhancements:

Temperature Control and Insulation

For processes involving high-viscosity fluids or those requiring constant temperatures, the valve can incorporate a Heating Jacket. This jacket envelops the main flow channel, allowing the circulation of steam, hot water, or thermal oil. This feature is crucial for preventing crystallization or a drastic increase in viscosity during discharge, ensuring smooth operation when handling molten polymers or high-concentration syrups.

Handling Corrosive Media

For extremely corrosive media, such as strong acids or bases, the ultimate defense may be the Glass-Lined bottom discharge valve. A layer of corrosion-resistant glass is fused to the metal substrate of the valve body, completely isolating the process media from the metal and guaranteeing long-term stability even under harsh chemical attack.

Delivering Comprehensive Fluid Control Solutions

Choosing the right valve requires deep process understanding. Vatten Valve is committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges. This expertise ensures that whether the requirement is for high purity, temperature control, or corrosion resistance, the optimal bottom discharge valve solution is provided.

English

English Deutsch

Deutsch Indonesia

Indonesia