Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the cont...

READ MORE

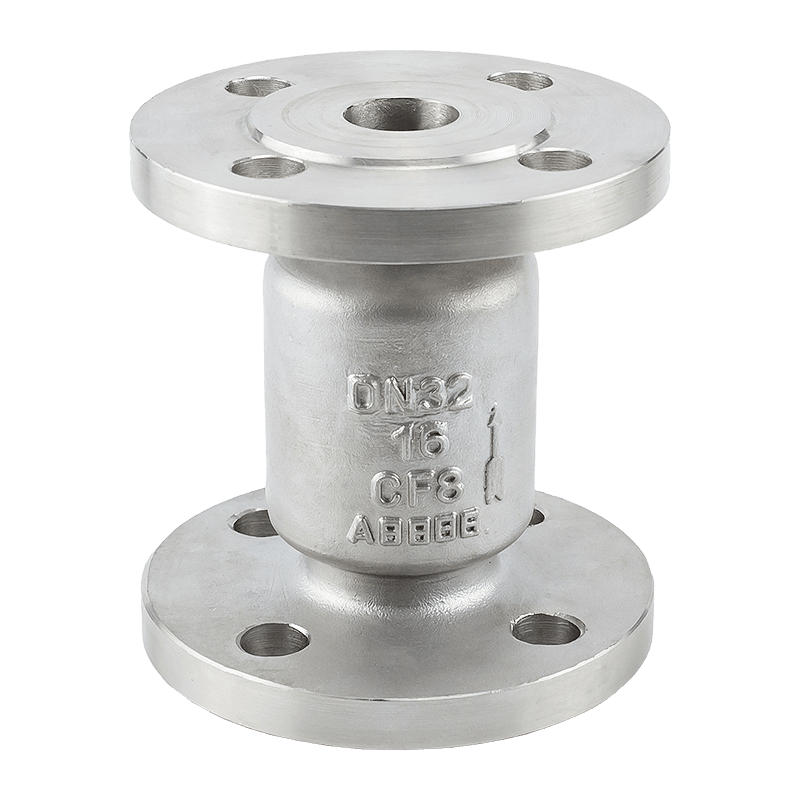

Check Valves Suppliers

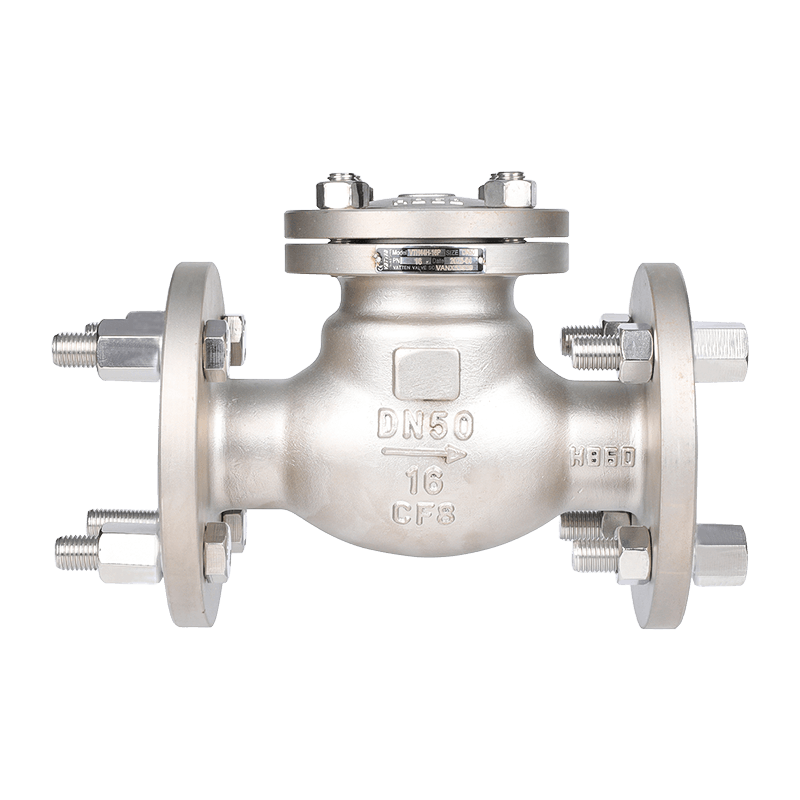

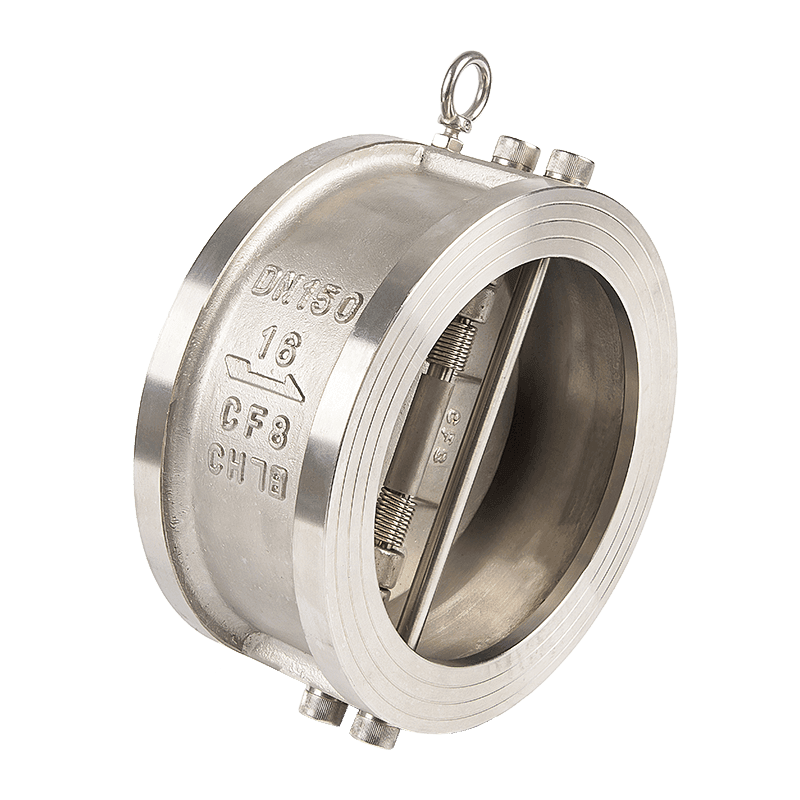

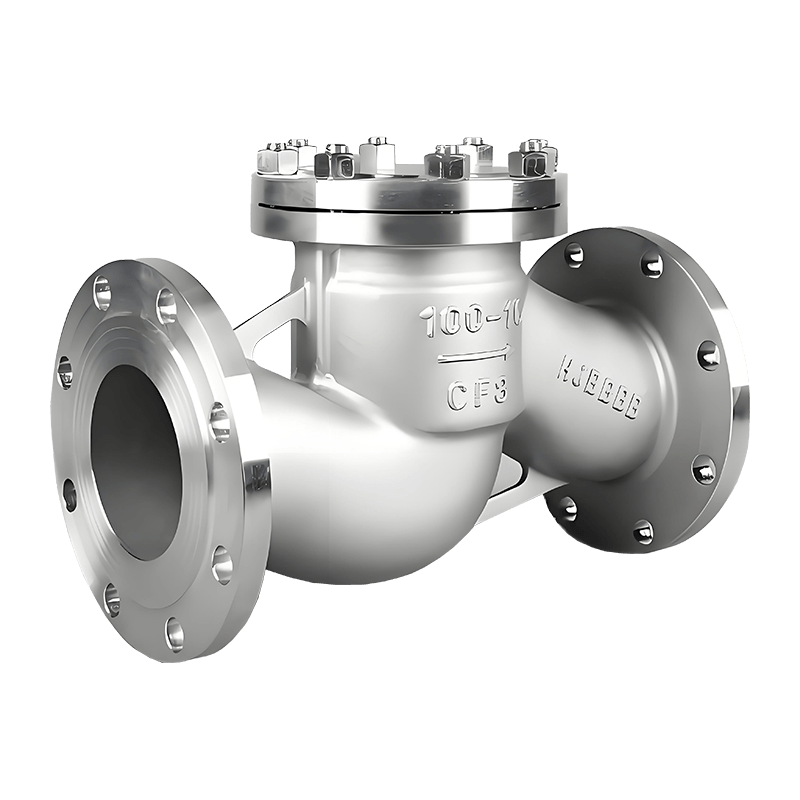

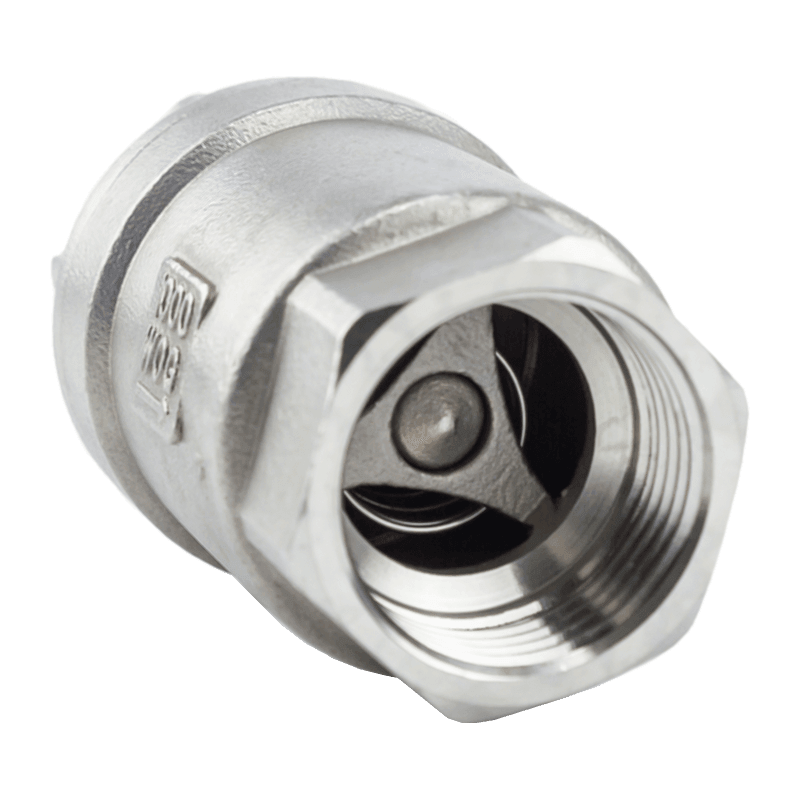

VATTEN's Check Valve product line offers reliable solutions for fluid control, featuring both Swing Check Valves and Lift Check Valves. These valves are designed to prevent backflow, ensuring smooth and efficient operations in various systems.

The Swing Check Valve is ideal for applications where space is limited, allowing for a smooth and reliable sealing action. Its design ensures a minimal risk of backflow, even in demanding environments. On the other hand, the Lift Check Valve operates with a simple yet effective lift mechanism, providing excellent performance in vertical piping systems, making it a preferred choice for many industrial setups.

One of the key advantages of VATTEN’s Check Valves is the versatility in materials. With options tailored to suit different environmental conditions and fluid types, these valves excel in a wide range of applications, from water treatment and chemical processing to oil and gas industries. Whether you need corrosion resistance, high-pressure endurance, or durability in extreme temperatures, VATTEN offers the perfect material solutions to meet your specific needs.

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

As Check Valves Suppliers and Check Valves Factory, the Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. Provide Custom Check Valves. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

-

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow co...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatic...

READ MORE -

Key Conclusion: Why Check Valves Are Essential in Fluid Systems Check valves are installed to allow fluid to flow in on...

READ MORE -

Such a scene often occurs during control valve selection meetings: The procurement manager asked: "Why not use this bal...

READ MORE

Check Valves: The Silent Guardians of Fluid Systems – A Deep Dive

The Check Valve, often referred to as a non-return valve (NRV) or one-way valve, is an indispensable component in industrial fluid control systems. Its core function is elegantly simple: to allow media to flow in one direction only while automatically preventing backflow, thus ensuring the stability and safety of the entire piping network.

I. The Indispensable Role and Core Value

Check valves operate autonomously, requiring no external power or manual intervention; their mechanism relies solely on the pressure differential of the medium itself. This self-actuating nature grants them quick, reliable response capabilities vital for system protection. This automaticity is a defining feature that Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, prioritizes in its product research. While Vatten Valve’s specialization is in core automation products like control ball valves, butterfly valves, and regulating valves, our expertise in precision motion control fundamentally underpins the reliability of all fluid systems, including the passive, but critical, function of check valves.

- Preventing Backflow: This is the paramount function. Check valves snap shut when the upstream pressure drops, such as during pump stoppage, preventing the dangerous and damaging reversal of flow.

- Protecting Sensitive Equipment: By stopping backflow, they safeguard costly and sensitive upstream machinery, like pumps, compressors, and turbines, from reverse rotation or pressure shock, significantly extending their service life.

- Mitigating Water Hammer: High-performance designs, like silent check valves, employ swift, spring-assisted closure to cushion the sudden pressure surge (water hammer) caused by flow reversal, a critical consideration in all high-speed fluid systems.

II. Principle of Operation and Valve Typology

All check valves consist of a body, a cover, and the internal sealing mechanism—the closure element (disc, ball, or piston)—and the seat. Forward flow pushes the closure element open. When the pressure drops or reverses, the element is instantly driven back onto the seat by the resulting pressure difference, gravity, or spring force.

Vatten Valve’s technological expertise, leveraged from our specialization in automatic control valves, allows us to deliver innovative solutions even in the most fundamental components. Our commitment to adhering to international quality standards ensures that every valve, regardless of complexity, offers superior performance. The check valve market features several critical designs differentiated by the movement of the closure element:

- Swing Check Valve: The disc is hinged, swinging open with forward flow. It offers minimal pressure drop and is suited for large pipelines and low-velocity media.

- Lift Check Valve: The disc moves vertically within guides. Known for excellent sealing, it is often used for high-pressure, high-velocity media like steam, water, or air.

- Wafer (Dual-Plate) Check Valve: This compact, lightweight design is clamped between flanges. Its dual spring-loaded discs close rapidly, minimizing water hammer and saving crucial space.

- Ball Check Valve: Uses a sphere as the closure element. Simple and reliable, it is ideal for viscous liquids or applications demanding minimal clogging.

III. Key Specifications and Sector Applications

Selecting the correct check valve requires meticulous attention to the operating environment. Key considerations include the nominal size, the pressure rating, and the body/seal material, which must be compatible with the media’s temperature and corrosiveness. Vatten Valve Group delivers these critical fluid control solutions to a wide spectrum of essential sectors, demonstrating the reach of our German precision manufacturing tradition.

We provide professional technical support and comprehensive solutions to industries including:

- Energy and Chemical: Ensuring process integrity in complex refining and transmission pipelines.

- Water Treatment: Preventing contamination and protecting pumping stations from backflow damage.

- Pharmaceutical and Food Processing: Meeting stringent material and sanitary requirements while maintaining precise, unidirectional flow control.

Our ongoing commitment to continuous innovation empowers our customers to confidently address complex industrial fluid control challenges, building upon our exceptional technological expertise developed at our roots in Saarland, Germany. Vatten Valve strives to be the trusted name in automated flow systems globally.

English

English Deutsch

Deutsch Indonesia

Indonesia