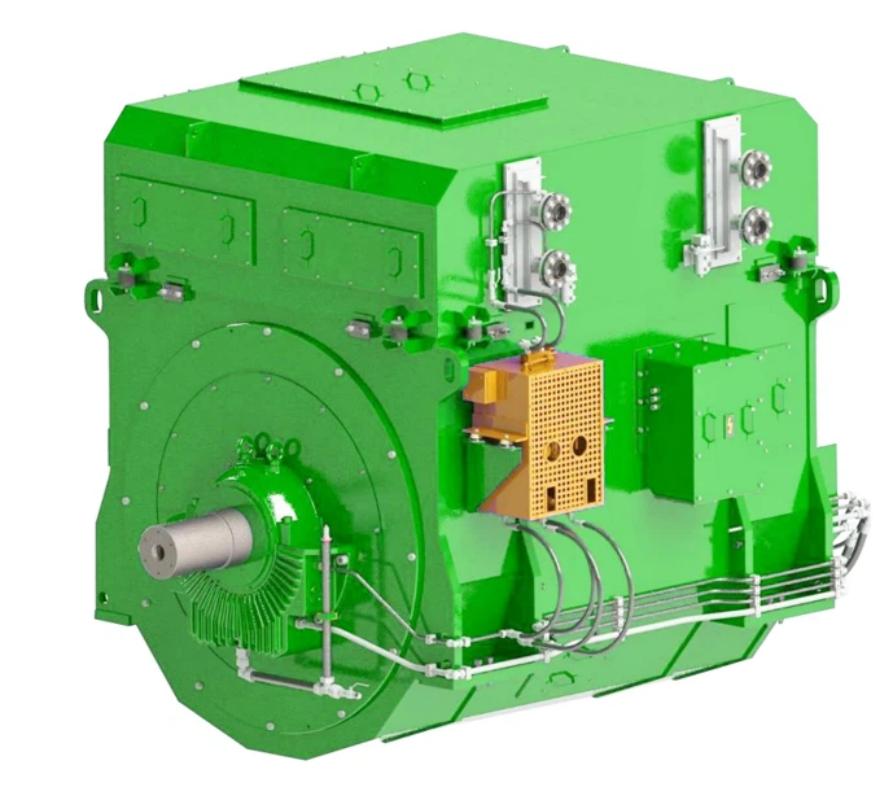

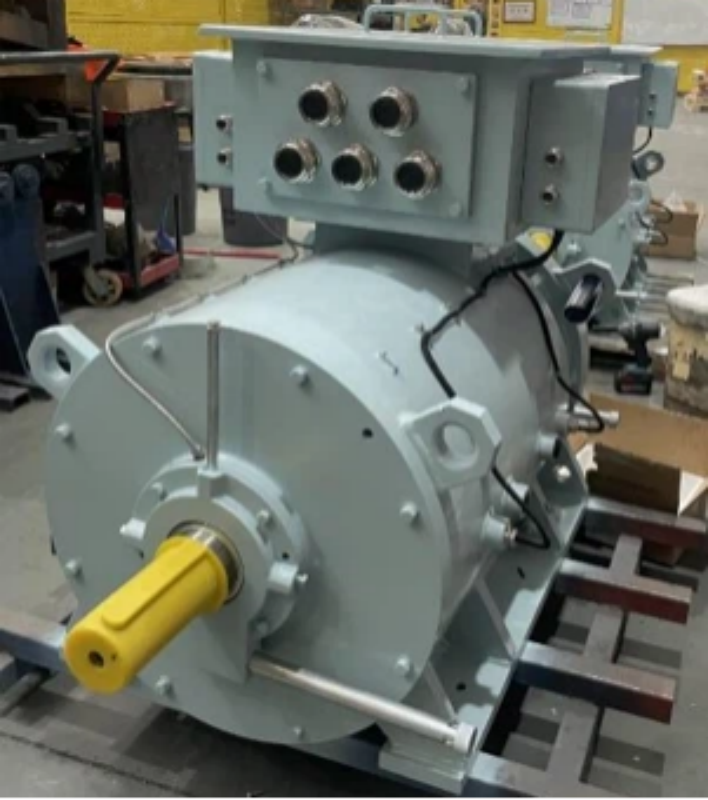

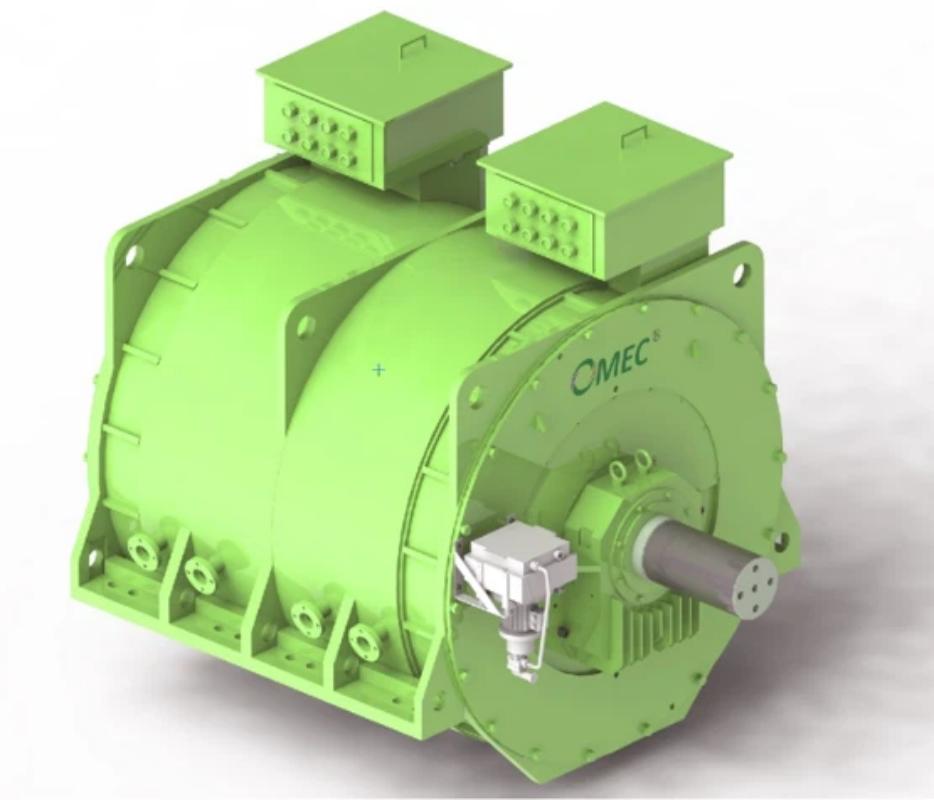

Mining Permanent Magnet Direct-Drive Motors

Mining Permanent Magnet Direct-Drive Motors Description

Direct-drive motors convert electrical energy directly into mechanical motion.By eliminating intermediate mechanical components like gears and belts, direct-drive technology delivers superior efficiency, enhanced reliability, and reduced maintenance requirements and costs.Within the mining sector, direct-drive motors are frequently utilized in hoists, conveyors, crushers, and similar equipment, substantially boosting both operational reliability and overall productivity.

Advantages

- Power Range: Mining equipment direct-drive motors typically have a large power range, from 0.55kW to 630kW, to meet the power requirements of various devices.

- High Torque, Low Speed: Mining equipment often needs to operate continuously under heavy load and low-speed conditions. For example, ore crushers require high torque to crush hard rocks, and underground conveyors need to transport materials at a stable low speed.

- Protection Level: Due to harsh mining environments, motors need to have a high protection level (usually IP65 or IP66) to prevent water, dust, and corrosion.

- High-Temperature Resistance: Motors must operate stably in high-temperature environments, typically requiring a working temperature range between -20°C and 60°C.

- High Efficiency and Energy Saving: Complying with international energy efficiency standards IE5 to reduce energy consumption and operating costs.

- Overload Capacity: Mining equipment often faces heavy load starts and sudden load changes. Motors need strong overload capacity, usually requiring an overload capacity of over 150%.

- Vibration and Noise Control: Motors should maintain low vibration and noise during operation to reduce interference with equipment and the environment.

| Magnetic Circuit Optimization | Utilizing high magnetic energy permanent magnet materials (such as neodymium iron boron) combined with multi-pole designs enhances the motor's torque output at low speeds, ensuring it can still output tens of thousands of Newton-meters of torque at speeds as low as 10-50 RPM. |

| Direct-Drive Structure | Eliminating intermediate components like reducers and couplings shortens the power transmission path, reducing energy loss by 5%-15% and avoiding efficiency decline due to gear wear. |

| Precise Control | Integrating variable frequency speed control technology allows real-time adjustment of speed and torque based on load requirements, preventing mechanical shocks caused by frequent starts, stops, or overloads in traditional motors. |

| Heat Dissipation Design | Optimizing the motor's heat dissipation structure and adopting forced air cooling technology to lower operating temperatures. |

| Enhanced Sealing Performance | Improving the motor's housing sealing design to enhance waterproof, dustproof, and corrosion-resistant capabilities, adapting to harsh working conditions. |

Product

Parameters

We can design and develop according to the needs of our customers to meet the requirements of different clients.

| Magnetic Circuit Optimization | Utilizing high magnetic energy permanent magnet materials (such as neodymium iron boron) combined with multi-pole designs enhances the motor's torque output at low speeds, ensuring it can still output tens of thousands of Newton-meters of torque at speeds as low as 10-50 RPM. |

| Direct-Drive Structure | Eliminating intermediate components like reducers and couplings shortens the power transmission path, reducing energy loss by 5%-15% and avoiding efficiency decline due to gear wear. |

| Precise Control | Integrating variable frequency speed control technology allows real-time adjustment of speed and torque based on load requirements, preventing mechanical shocks caused by frequent starts, stops, or overloads in traditional motors. |

| Heat Dissipation Design | Optimizing the motor's heat dissipation structure and adopting forced air cooling technology to lower operating temperatures. |

| Enhanced Sealing Performance | Improving the motor's housing sealing design to enhance waterproof, dustproof, and corrosion-resistant capabilities, adapting to harsh working conditions. |

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Mining Permanent Magnet Direct-Drive Motors Suppliers and Mining Permanent Magnet Direct-Drive Motors Factory. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

The Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. We are committed to continuous innovation, providing customers with superior performance products, Mining Permanent Magnet Direct-Drive Motors Wholesale, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the control valve cannot stably maintain an appropriate position to sustain the predetermined process conditions. This condition causes the process variables in the closed-loop system to fluctuate around thei...

READ MORE -

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow controlled release of bulk solids, slurries, or liquids by gravity. They are a critical component in industries ranging from food processing and pharmaceuticals to chemical manufacturing and wastewater ...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatically using an electric actuator that adjusts valve position based on control signals. They provide precise, repeatable flow regulation, remote automation capability, and reduced manual intervention, m...

READ MORE

English

English Deutsch

Deutsch Indonesia

Indonesia