Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the control valve cannot stably maintain an appropriate position to sustain the predetermined proc...

READ MORE

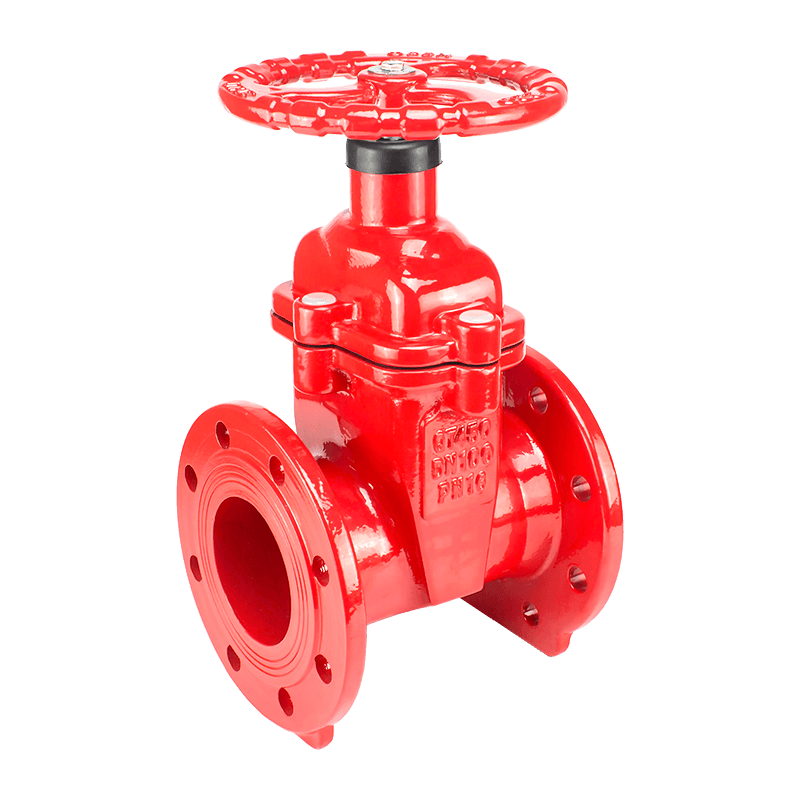

Manual Gate Valves Manufacturers

VATTEN electric knife gate valves are equipped with high-performance motors that enable precise valve operation without the need for an external air supply. This ensures efficiency and reliability, especially in environments where compressed air is unavailable or impractical. The powerful torque of the electric actuator ensures secure closure even under tough conditions, such as in mining and slag processing.

These valves are well-suited for use in harsh environments where traditional manual or pneumatic valves may not perform as effectively. The high torque of the motor allows the valve to achieve a tight shutoff, even when handling challenging media like slurries and coal slag. This makes them ideal for maintaining operational efficiency and preventing leaks or blockages.

With their robust design and ability to function without the need for an air supply, VATTEN electric knife gate valves provide a versatile and cost-effective solution for industries requiring reliable valve control in demanding conditions.

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

As Manual Gate Valves Manufacturers and Manual Gate Valves Company, the Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. Provide Custom Manual Gate Valves. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

-

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow controlled release of bulk solids, slurries, or liquids by gravity. They are a critical comp...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatically using an electric actuator that adjusts valve position based on control signals. They...

READ MORE -

Key Conclusion: Why Check Valves Are Essential in Fluid Systems Check valves are installed to allow fluid to flow in only one direction and automatically prevent reverse flow without manual intervention. Their...

READ MORE

What Are the Key Applications of Manual Gate Valves in Industrial Systems?

Manual gate valves are widely used in industrial systems to control the flow of liquids, gases, and other materials. These valves are designed to either fully open or fully close the flow of a system, making them ideal for on/off control. Unlike other types of valves, manual gate valves are not typically used for throttling, as partial openings can cause damage to the sealing surfaces. This article explores the key applications of manual gate valves in various industries, examining their advantages, performance characteristics, and typical uses in different sectors.

What Are Manual Gate Valves?

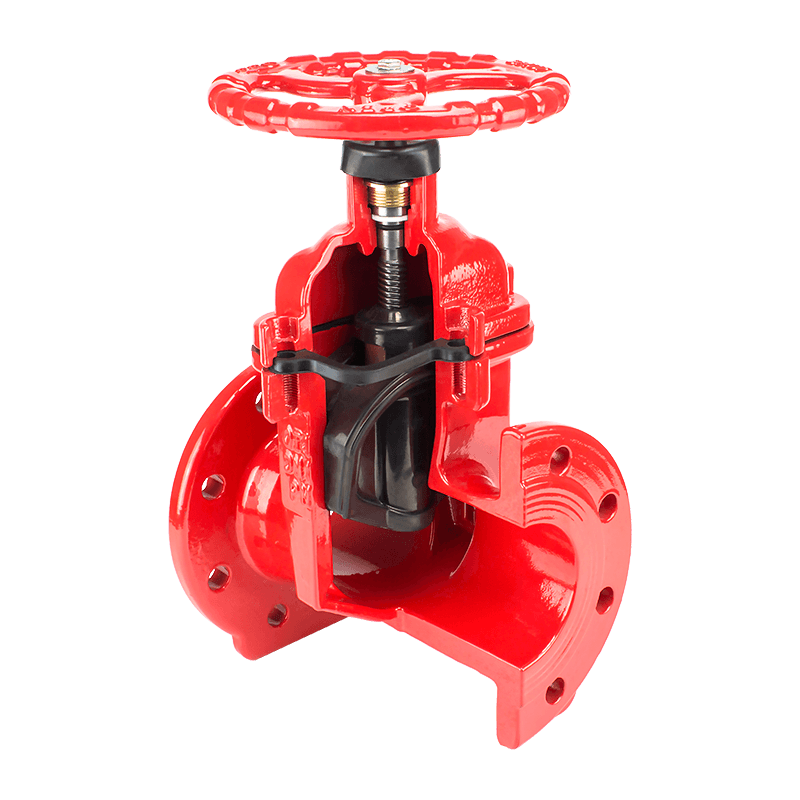

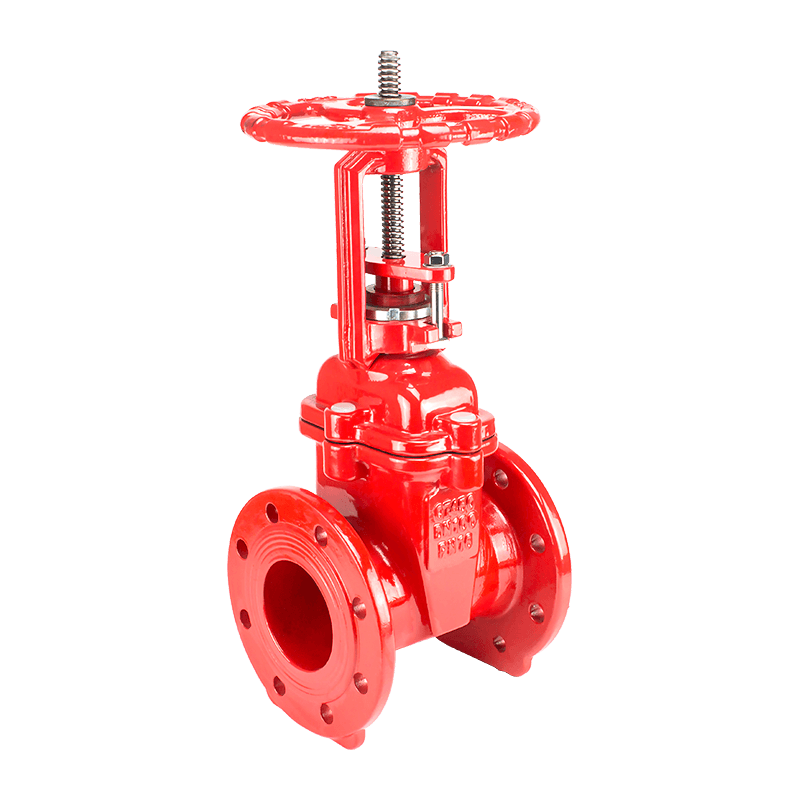

A manual gate valve is a mechanical valve that uses a sliding gate (or wedge) to control the flow of fluids or gases. The gate is raised or lowered by turning a handwheel or lever, allowing the user to either block or allow flow within the pipe or system. Manual gate valves are typically used in systems that require a simple, straightforward on/off control, where the valve will either be fully open or fully closed.

While manual gate valves offer basic operation, they are highly reliable and durable, especially in situations where precise flow regulation is not required. These valves are commonly used in a wide range of industrial applications due to their robust construction and cost-effectiveness.

Key Applications of Manual Gate Valves

1. Water and Wastewater Treatment

Manual gate valves are commonly used in water treatment plants and wastewater treatment systems. These systems often require valves that can effectively shut off or start the flow of water, sewage, or treated liquids. The manual operation of the gate valve provides reliable control without the complexity or cost of automated valves, which may not always be necessary in such systems.

- Water Distribution Systems: Manual gate valves are used to isolate different sections of water treatment plants, allowing maintenance or repairs to be done without affecting the entire system.

- Sewage Treatment: These valves help in controlling the flow of untreated sewage or treated effluent during various stages of the treatment process.

- Pressure Control: Gate valves are often used for controlling the flow to maintain the required pressure in pipelines.

2. Oil and Gas Industry

The oil and gas industry relies heavily on manual gate valves for a wide range of applications. These industries require valves that can handle high pressures, large volumes of liquid or gas, and the potential for abrasive or corrosive materials. Manual gate valves are used in pipeline systems, refineries, and offshore platforms due to their simplicity, strength, and ability to control flow efficiently in harsh environments.

- Pipeline Isolation: Manual gate valves are used to isolate sections of pipelines during maintenance or emergency shutdowns, preventing leaks and ensuring safety.

- Refineries: Manual gate valves are often found in refinery processes for regulating the flow of crude oil or refined products. These valves can handle the high pressures and temperatures associated with refining processes.

- Offshore Platforms: Manual gate valves are used in offshore oil rigs to control the flow of oil and gas, with the added benefit of being operable in tough environmental conditions.

3. Chemical Processing

In chemical plants, manual gate valves play a crucial role in controlling the flow of various chemicals, gases, and liquids through pipelines. These valves are typically chosen for their robustness, ease of operation, and their ability to withstand the corrosive nature of chemicals. Depending on the chemical being handled, manual gate valves may be made of corrosion-resistant materials such as stainless steel, ensuring reliable operation over time.

- Flow Isolation: Manual gate valves are often used to isolate certain parts of the chemical process for maintenance or in case of emergencies.

- Corrosive Fluids: For handling corrosive chemicals, gate valves made from materials like stainless steel or alloy steels are used to resist wear and tear.

- Process Control: Manual gate valves can be used to control the flow rate of certain chemicals in batch processes where precise adjustments are not required.

4. Power Generation

In power generation plants, particularly in steam and hydraulic systems, manual gate valves are commonly used for controlling the flow of steam, water, or oil. These valves help in managing the flow of fluids to various parts of the system, ensuring optimal performance of turbines and generators. They are also used to shut off sections of the system for maintenance or repair work.

- Steam Flow Control: Manual gate valves are used to control steam flow in boilers and turbines, maintaining the pressure required for efficient energy generation.

- Hydraulic Systems: In hydroelectric plants, manual gate valves are used to regulate water flow through turbines for power generation.

- Isolation During Maintenance: During shutdowns or repairs, manual gate valves can isolate certain sections of the plant, ensuring safety and preventing contamination of fluids.

5. HVAC (Heating, Ventilation, and Air Conditioning)

Manual gate valves are widely used in HVAC systems, particularly in large industrial settings or commercial buildings. These valves are used for controlling the flow of heating fluids (such as hot water or steam) and chilled water throughout the system. Gate valves are essential for balancing the flow in cooling towers, boilers, and air handling units, as they provide simple yet effective flow control.

- Flow Regulation: Manual gate valves are used to control the flow of water through pipes and radiators, ensuring balanced heating or cooling in the system.

- Shutoff for Repairs: When sections of the HVAC system need maintenance, gate valves can quickly shut off the water or steam flow, allowing workers to safely conduct repairs.

- System Isolation: In large-scale HVAC systems, manual gate valves are employed to isolate different sections of the system, allowing for efficient operation and maintenance.

6. Food and Beverage Industry

In the food and beverage industry, manual gate valves are often used for regulating the flow of liquids, slurries, and other materials. These valves are chosen for their reliability and ability to handle high flow rates without compromising on cleanliness or hygiene. Stainless steel or food-grade materials are typically used for manufacturing these valves to ensure compliance with industry standards and regulations.

- Liquid Flow Control: Manual gate valves control the flow of ingredients in food processing lines, ensuring that the right amount of fluid is delivered to each stage of production.

- Sanitary Standards: Stainless steel gate valves are used to maintain sanitary conditions in food production, ensuring the safe transport of liquids or food-based products without contamination.

- Batch Processes: Manual gate valves can isolate specific portions of production lines for cleaning or maintenance, ensuring that production runs smoothly without contamination between batches.

Advantages of Manual Gate Valves

Manual gate valves offer several key advantages that make them suitable for use in various industrial applications:

- Simple Operation: Manual gate valves are easy to operate, requiring no external power source. The user can manually control the valve with a handwheel or lever.

- Cost-Effective: Compared to automated valve systems, manual gate valves are more affordable and provide a cost-effective solution for many applications. ```html

- Durability: Manual gate valves are known for their long lifespan, especially in tough environments. They are built to withstand high pressures and resist wear and tear over time, making them a reliable option in industrial settings.

- Minimal Maintenance: Unlike automated valves, manual gate valves have fewer components that can break or require frequent maintenance, resulting in lower overall maintenance costs.

- Versatility: Manual gate valves are versatile and can be used in a wide range of applications, from high-pressure systems in oil and gas to low-pressure water systems in municipal infrastructure.

Conclusion

Manual gate valves are essential components in many industrial systems due to their simplicity, reliability, and versatility. Whether used in water treatment, oil and gas, chemical processing, power generation, or HVAC systems, these valves provide cost-effective solutions for controlling the flow of fluids and gases. Their ability to operate effectively without the need for automation makes them a preferred choice in situations where full control over flow is required, but automation is not necessary. Their robust construction, durability, and ease of maintenance make manual gate valves a popular choice for industries around the world.

English

English Deutsch

Deutsch Indonesia

Indonesia