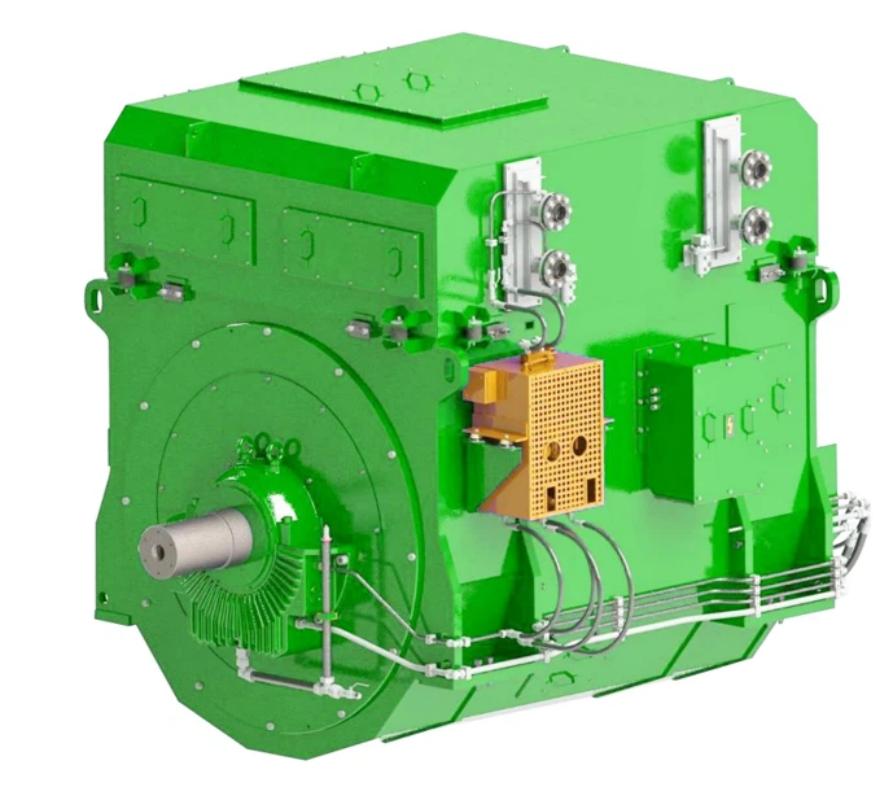

IE4 High Efficiency Motor

IE4 High Efficiency Motor Description

IE4 high-efficiency motors represent the highest energy efficiency class in the International Electrotechnical Commission (IEC) standards, signifying superior energy savings. Compared to IE1 motors, IE4 motors reduce energy costs by 14%, while achieving 3% higher efficiency than IE3 motors. This provides IE4 motors with significant energy-saving advantages, particularly in continuous-duty applications such as pumps, fans, and compressors.

IE4 motors achieve their superior performance through sophisticated engineering and high-quality materials. Key design features such as optimized stator and rotor slot configurations, precision-calibrated fan parameters, and sinusoidal windings work systematically to minimize power loss and maximize efficiency.

While the use of premium materials results in higher initial costs compared to IE1 models, it delivers tangible operational benefits: significantly reduced energy consumption, lower operating temperatures, extended service life, and decreased maintenance requirements. These advantages collectively make IE4 motors a strategic choice for enhancing long-term operational efficiency.

IE4 motors demonstrate exceptional versatility across multiple sectors, including industrial manufacturing, agricultural operations, and food processing. They are designed to perform reliably in diverse environments, excluding those containing flammable, explosive, or corrosive gases. These motors typically operate at a standard voltage of 380V, with compatible frequencies of 50Hz or 60Hz, and are available in various power ratings and pole configurations to suit specific application requirements.

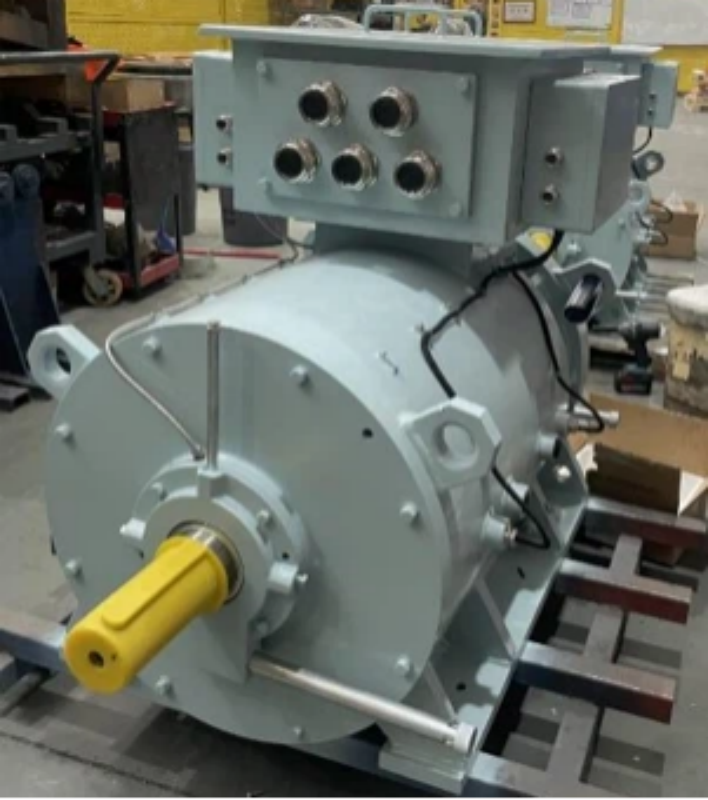

| Brand | Ciitto Servo |

| Motor types | TYGXP |

| Efficiency | IE4/IE5 |

| Output | 1500r/min, 132kW, 840Nm |

| AC volages | All volages |

| Poles | 4 |

| Power Factor | 0.95 |

| Country of origin | China |

| Working system | S1 |

| Protection | IP55 |

| Insulation class | F |

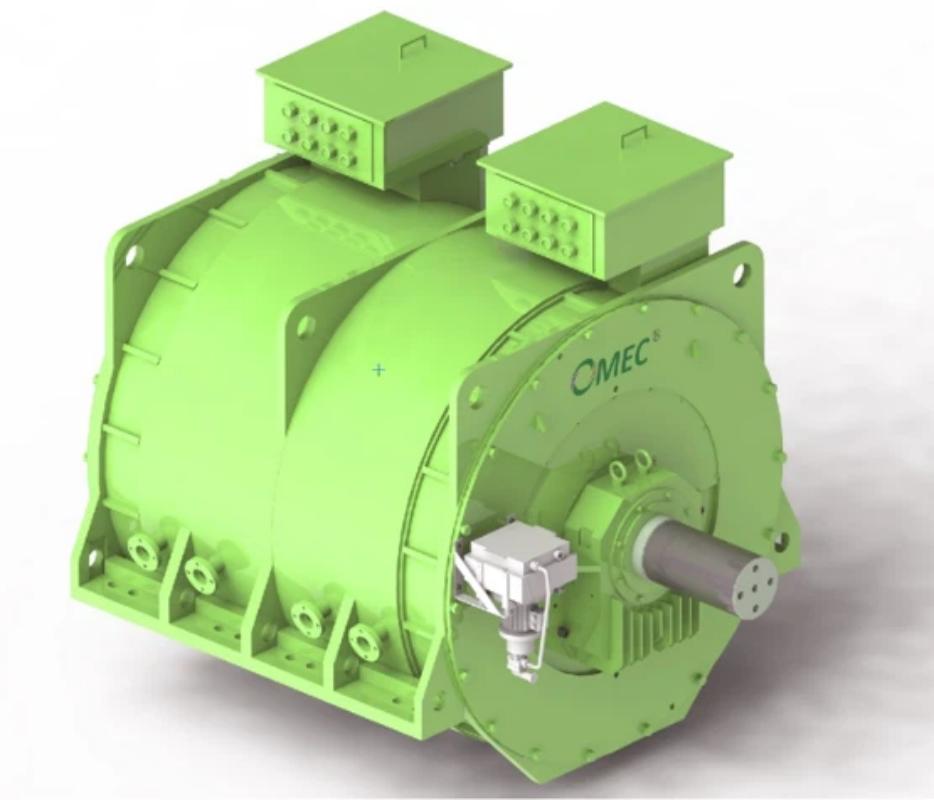

Product

Parameters

We can design and develop according to the needs of our customers to meet the requirements of different clients.

| Brand | Ciitto Servo |

| Motor types | TYGXP |

| Efficiency | IE4/IE5 |

| Output | 1500r/min, 132kW, 840Nm |

| AC volages | All volages |

| Poles | 4 |

| Power Factor | 0.95 |

| Country of origin | China |

| Working system | S1 |

| Protection | IP55 |

| Insulation class | F |

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. IE4 High Efficiency Motor Suppliers and IE4 High Efficiency Motor Factory. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

The Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. We are committed to continuous innovation, providing customers with superior performance products, IE4 High Efficiency Motor Wholesale, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the control valve cannot stably maintain an appropriate position to sustain the predetermined process conditions. This condition causes the process variables in the closed-loop system to fluctuate around thei...

READ MORE -

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow controlled release of bulk solids, slurries, or liquids by gravity. They are a critical component in industries ranging from food processing and pharmaceuticals to chemical manufacturing and wastewater ...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatically using an electric actuator that adjusts valve position based on control signals. They provide precise, repeatable flow regulation, remote automation capability, and reduced manual intervention, m...

READ MORE

English

English Deutsch

Deutsch Indonesia

Indonesia