Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the control valve cannot stably maintain an appropriate position to sustain the predetermined proc...

READ MORE

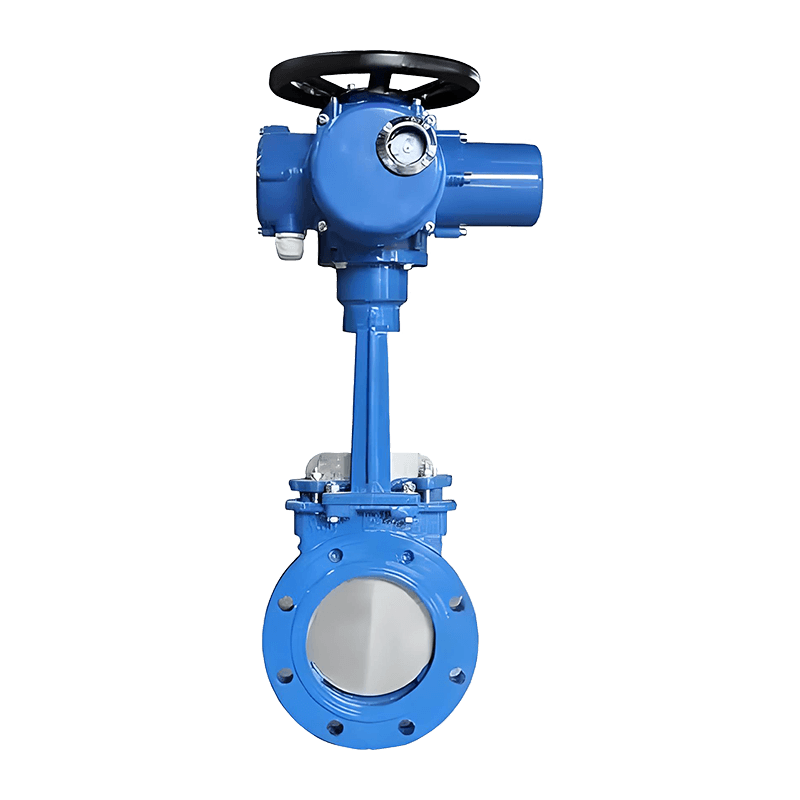

Electric Knife Gate Valves Manufacturers

VATTEN electric knife gate valves are equipped with high-performance motors that enable precise valve operation without the need for an external air supply. This ensures efficiency and reliability, especially in environments where compressed air is unavailable or impractical. The powerful torque of the electric actuator ensures secure closure even under tough conditions, such as in mining and slag processing.

These valves are well-suited for use in harsh environments where traditional manual or pneumatic valves may not perform as effectively. The high torque of the motor allows the valve to achieve a tight shutoff, even when handling challenging media like slurries and coal slag. This makes them ideal for maintaining operational efficiency and preventing leaks or blockages.

With their robust design and ability to function without the need for an air supply, VATTEN electric knife gate valves provide a versatile and cost-effective solution for industries requiring reliable valve control in demanding conditions.

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

As Electric Knife Gate Valves Manufacturers and Electric Knife Gate Valves Company, the Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. Provide Custom Electric Knife Gate Valves. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

-

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow controlled release of bulk solids, slurries, or liquids by gravity. They are a critical comp...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatically using an electric actuator that adjusts valve position based on control signals. They...

READ MORE -

Key Conclusion: Why Check Valves Are Essential in Fluid Systems Check valves are installed to allow fluid to flow in only one direction and automatically prevent reverse flow without manual intervention. Their...

READ MORE

Electric Knife Gate Valve Actuator Maintenance Tips

Proper maintenance of the electric actuator is critical for the long-term performance of knife gate valves. Regular inspection of the actuator’s gear, motor, and electrical connections can prevent unexpected downtime. Lubrication schedules should follow manufacturer guidelines, typically requiring grease application to moving parts every 3–6 months depending on usage frequency. Ensuring that the actuator's travel limits are calibrated correctly can prevent damage to the gate and the seat.

Material Selection for Severe Service Applications

Electric knife gate valves in abrasive or corrosive environments require careful material selection to extend service life. Key options include:

- Body: Stainless steel 316 or duplex stainless steel for high corrosion resistance.

- Gate: Hard-faced or tungsten carbide-coated gates for abrasion resistance.

- Seals: PTFE or reinforced elastomers suitable for chemical resistance and high temperature.

Automation Integration Considerations

When integrating electric knife gate valves into automated systems, signal compatibility and feedback mechanisms are crucial. Valves with integrated position feedback allow remote monitoring of open/closed status, which improves process safety. Choosing actuators with Modbus or Profibus communication interfaces can simplify integration with SCADA systems. Additionally, specifying valves with adjustable opening/closing speeds helps mitigate water hammer in pipelines.

Common Troubleshooting Scenarios

Electric knife gate valves may encounter operational issues that are often overlooked:

- Valve fails to open or close: check actuator power supply and manual override alignment.

- Leakage past the gate: inspect seat condition and ensure no debris is lodged in the sealing surface.

- Slow operation: verify actuator lubrication, gear condition, and control signal voltage.

Performance Comparison Table

| Actuation Type | Speed | Maintenance Frequency | Ideal Application |

| Electric | Medium | Moderate | Automated processes, high cycle |

| Pneumatic | Fast | High | Rapid on/off applications |

| Manual | Slow | Low | Low-cycle, maintenance-friendly |

Environmental Protection and Compliance

Compliance with environmental standards is increasingly important for industrial valve applications. Selecting electric knife gate valves with RoHS-compliant materials and low-leakage designs reduces environmental impact. In wastewater treatment or chemical industries, ensuring valves meet EPA and local discharge regulations is critical. Additionally, using actuators with energy-efficient motors can lower operational costs and carbon footprint over the valve’s lifecycle.

English

English Deutsch

Deutsch Indonesia

Indonesia