Direct Drive Bead Mill Motor

Direct Drive Bead Mill Motor Description

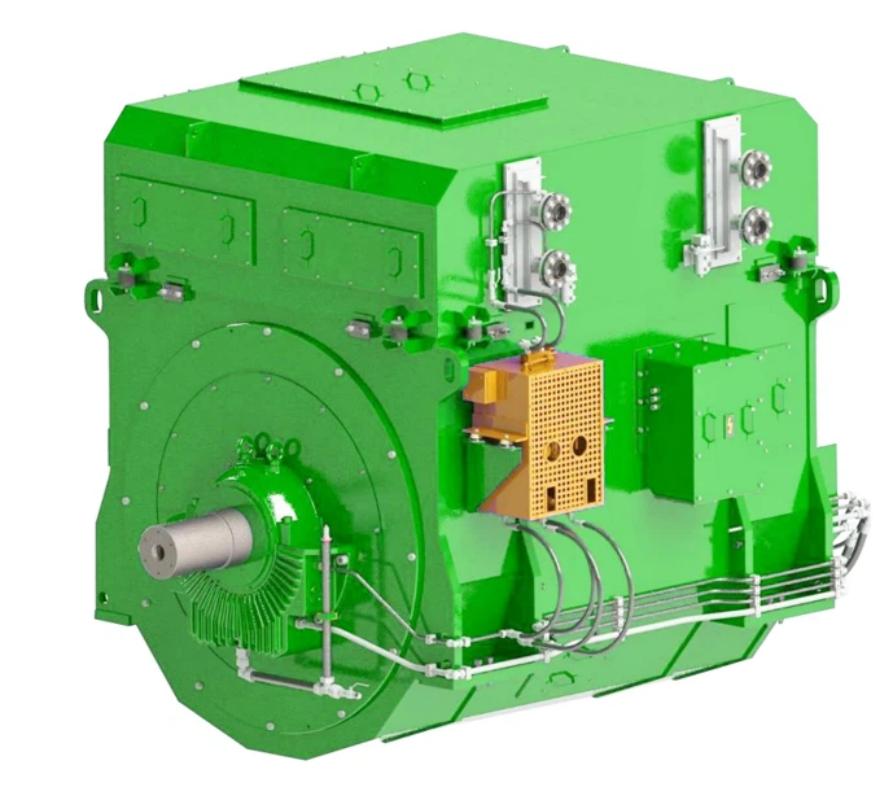

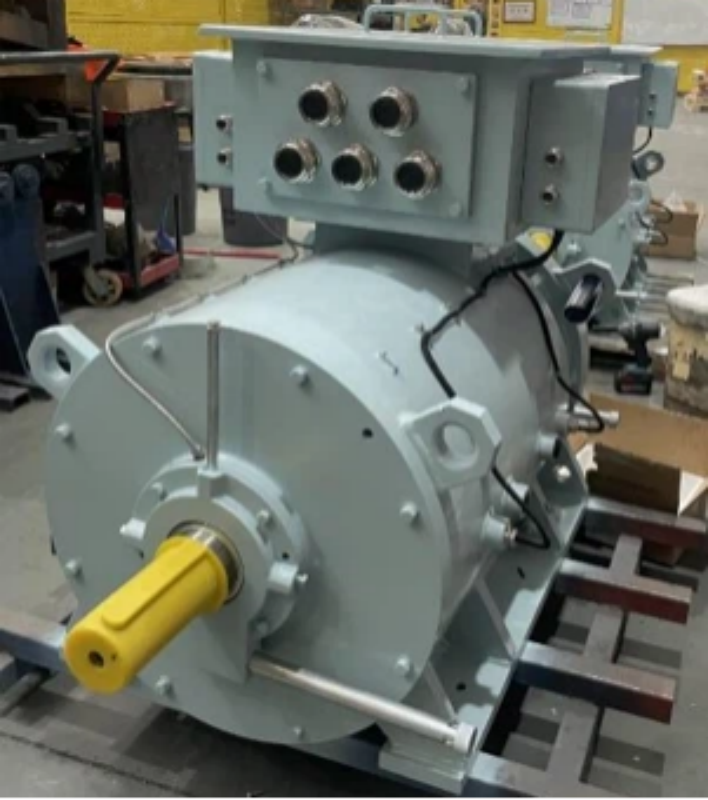

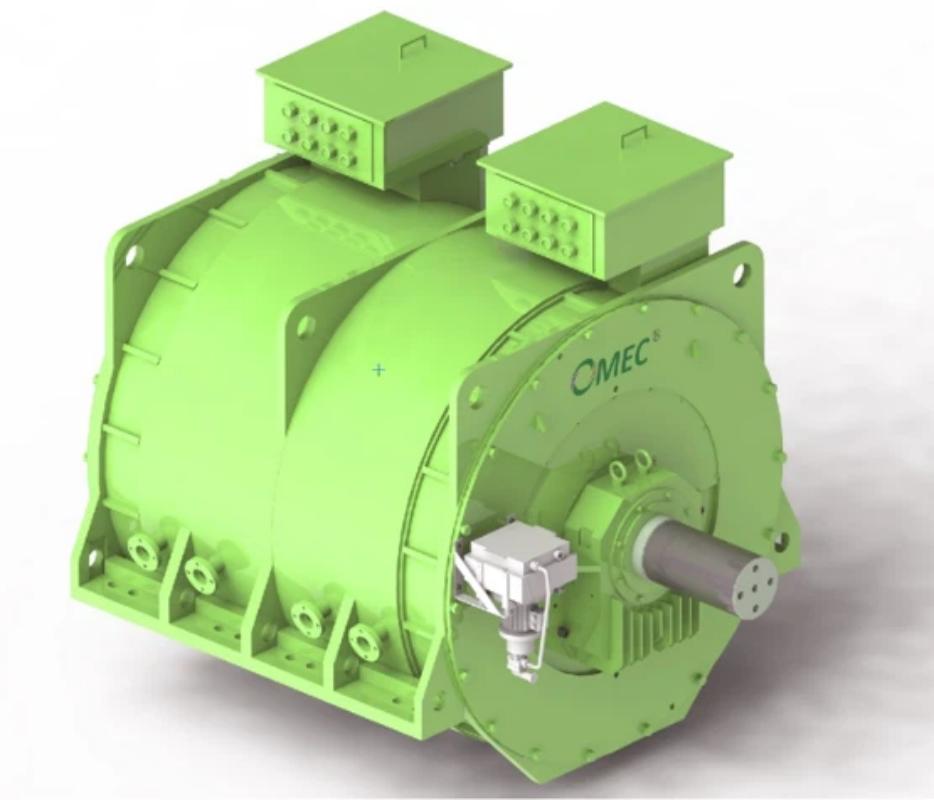

This is a purpose-built permanent magnet synchronous direct drive motor, specifically engineered for bead and sand mills in demanding applications such as paints, inks, chemicals, battery materials, and nano-grinding lines. It delivers high torque at low speeds, coupled with ultra-low vibration, high efficiency, and robust reliability for continuous duty cycles.

Key Advantages

- High Torque At Low Speed:Direct coupling eliminates gearbox losses. Strong starting torque and stable output across the mill's working range (typ. 50–600 rpm configurable).

- Low Vibration, Low Noise:Rotor dynamic balancing and optimized electromagnetic design reduce vibration transfer to bearings and grinding chamber, improving product fineness consistency.

- Energy-Efficient:PMSM efficiency up to IE4/IE5-level performance (application dependent), lowering kWh per ton and heat generation inside the mill.

- Rugged & Safe:Industrial sealing and optional Explosion-Proof execution for solvent-based processes. High ingress protection and corrosion-resistant finishes.

- Precision Control:Works with vector drives for smooth speed/torque control, quick response to load changes, and protection against jamming or media surge.

- Easy Integration:Direct-drive shaft/flange options for common bead/sand mill interfaces; encoder and thermal sensor kits for plug-and-play commissioning.

Application Scenarios

Bead/Sand mills for paints, inks, coatings, pigments

Cathode/anode materials, ceramic slurries, nano-composites

Chemical additives, dyes, electronic paste, and specialty chemicals

| Power Range | 7.5 – 200 kW (custom up to 315 kW) |

| Speed Range | 50 – 1,200 rpm (continuous, field-weakened as required) |

| Rated Torque | 150 – 3,500 N·m (model dependent) |

| Voltage / Frequency | 380 – 690 V, 50/60 Hz via VFD |

| Efficiency | High efficiency PMSM (application-dependent up to IE4/IE5 levels) |

| Cooling | IC411 (TEFC), IC86W (water-cooled) optional for compact footprint |

| Protection | IP55 / IP65 (process-side sealing options) |

| Duty | S1 continuous; thermal class F/H with Class B temperature rise (typ.) |

| Sensors | PT100/PT1000, PTC; incremental/absolute encoder options |

| Explosion-Proof | ATEX/IECEx options for hazardous areas (on request) |

| Shaft/Flange | Customized shaft end, keyway, and flange patterns for bead/sand mills |

| Bearings | Heavy-duty bearings with enhanced sealing and grease/relubrication options |

| Finish | Anti-corrosion paint systems for solvents and cleaning agents |

Product

Parameters

We can design and develop according to the needs of our customers to meet the requirements of different clients.

| Power Range | 7.5 – 200 kW (custom up to 315 kW) |

| Speed Range | 50 – 1,200 rpm (continuous, field-weakened as required) |

| Rated Torque | 150 – 3,500 N·m (model dependent) |

| Voltage / Frequency | 380 – 690 V, 50/60 Hz via VFD |

| Efficiency | High efficiency PMSM (application-dependent up to IE4/IE5 levels) |

| Cooling | IC411 (TEFC), IC86W (water-cooled) optional for compact footprint |

| Protection | IP55 / IP65 (process-side sealing options) |

| Duty | S1 continuous; thermal class F/H with Class B temperature rise (typ.) |

| Sensors | PT100/PT1000, PTC; incremental/absolute encoder options |

| Explosion-Proof | ATEX/IECEx options for hazardous areas (on request) |

| Shaft/Flange | Customized shaft end, keyway, and flange patterns for bead/sand mills |

| Bearings | Heavy-duty bearings with enhanced sealing and grease/relubrication options |

| Finish | Anti-corrosion paint systems for solvents and cleaning agents |

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Direct Drive Bead Mill Motor Suppliers and Direct Drive Bead Mill Motor Factory. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

The Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. We are committed to continuous innovation, providing customers with superior performance products, Direct Drive Bead Mill Motor Wholesale, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the control valve cannot stably maintain an appropriate position to sustain the predetermined process conditions. This condition causes the process variables in the closed-loop system to fluctuate around thei...

READ MORE -

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow controlled release of bulk solids, slurries, or liquids by gravity. They are a critical component in industries ranging from food processing and pharmaceuticals to chemical manufacturing and wastewater ...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatically using an electric actuator that adjusts valve position based on control signals. They provide precise, repeatable flow regulation, remote automation capability, and reduced manual intervention, m...

READ MORE

English

English Deutsch

Deutsch Indonesia

Indonesia