Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the cont...

READ MORE

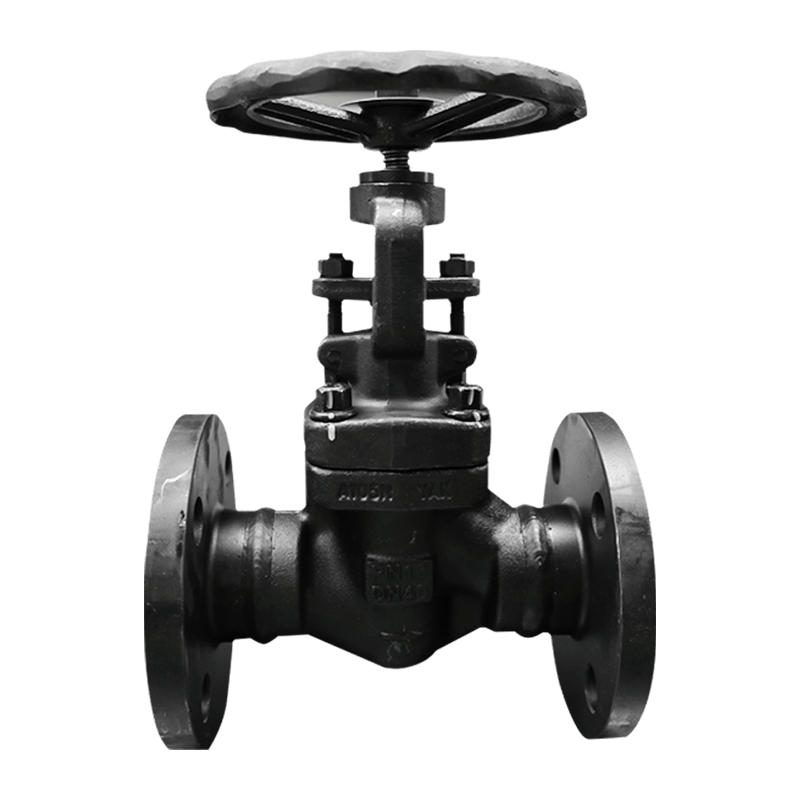

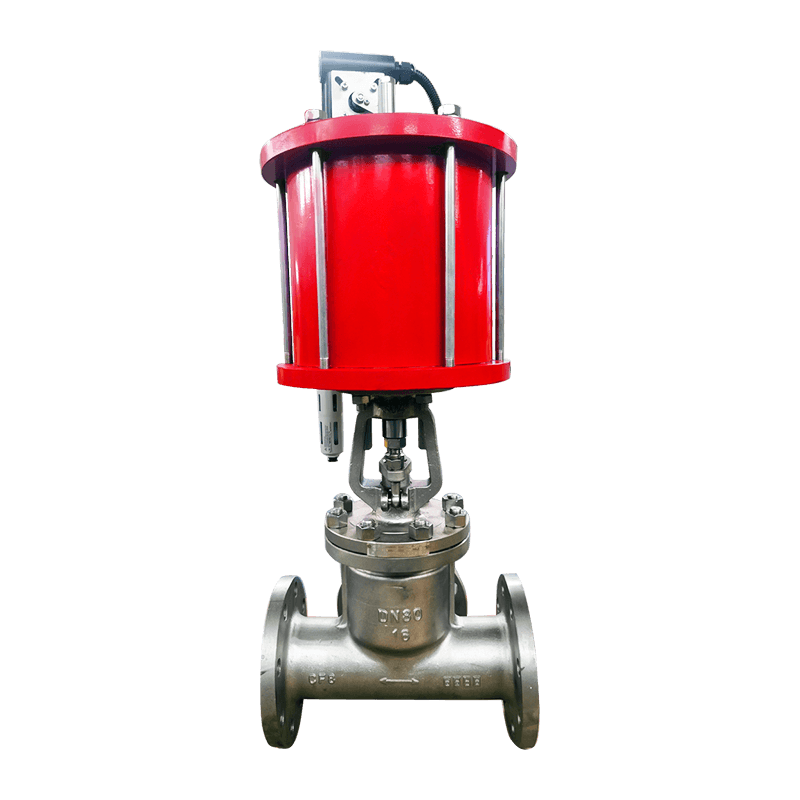

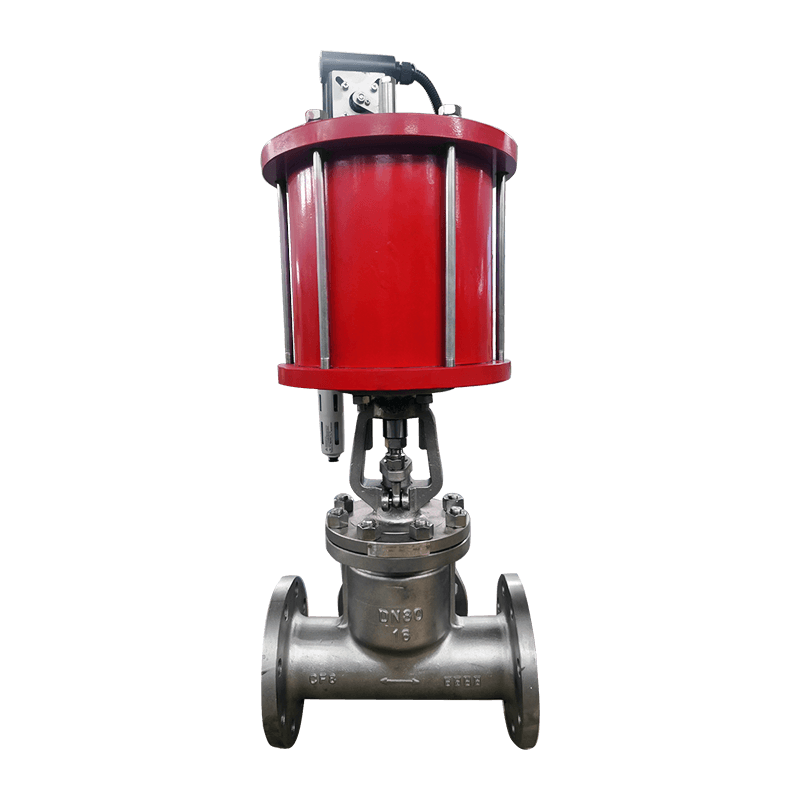

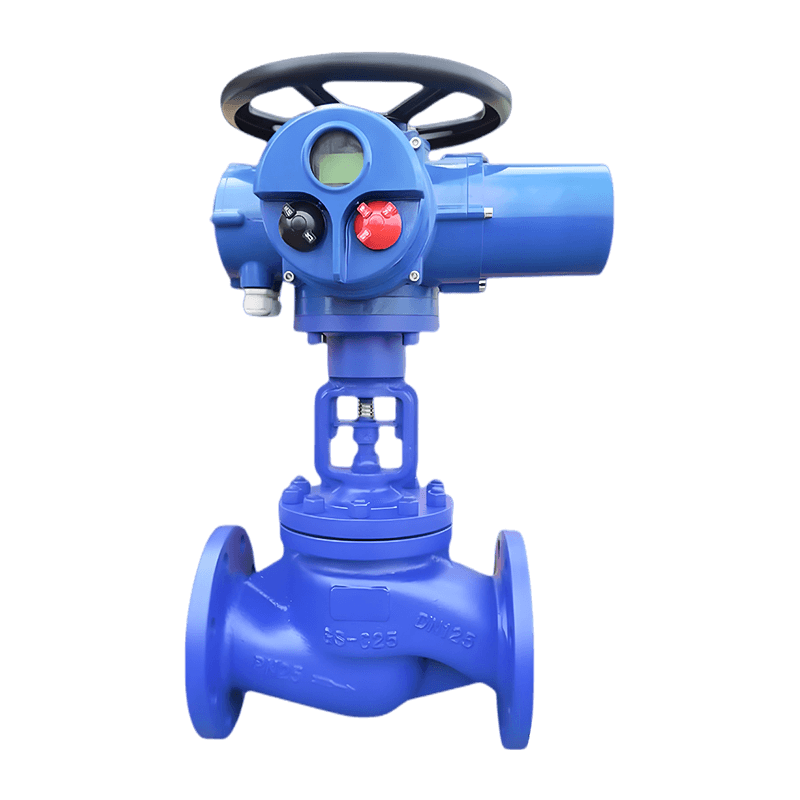

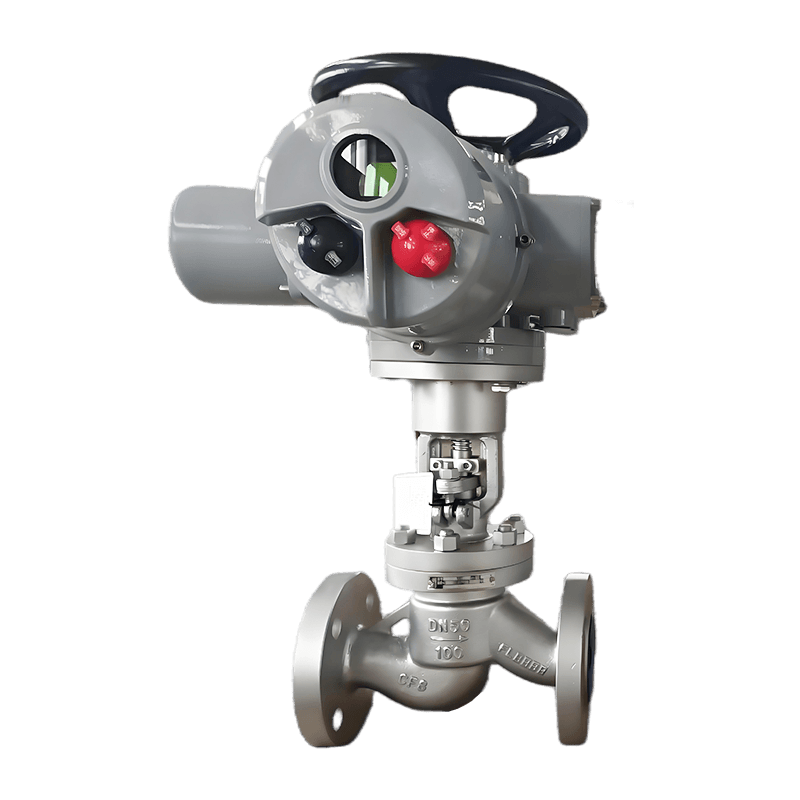

Carbon Steel/Stainless Steel Stop Valves Suppliers

VATTEN offers a comprehensive range of stop valves designed to meet the diverse needs of various industrial applications. These valves come in pneumatic, electric, and manual versions, providing flexibility to cater to different operational requirements. Each type is engineered for high performance, ensuring smooth and reliable flow control in challenging environments.

Our stop valves are built to withstand extreme conditions, including high temperatures and pressures. The robust construction ensures that they remain fully operational even in demanding environments, making them ideal for industries such as chemical processing, power generation, and water treatment.

With excellent thermal insulation properties, our valves are designed to prevent temperature changes from affecting the operation, thereby improving overall efficiency. Additionally, VATTEN stop valves are known for their superior safety features, offering peace of mind in terms of both operational reliability and user protection.

Whether you need precise control in high-temperature systems or robust performance under pressure, VATTEN’s stop valves are engineered to deliver unmatched reliability and safety across a variety of demanding applications.

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

As Carbon Steel Stop Valves Suppliers and Stainless Steel Stop Valves Factory, the Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. Provide Custom Shut Off Valves. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

-

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow co...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatic...

READ MORE -

Key Conclusion: Why Check Valves Are Essential in Fluid Systems Check valves are installed to allow fluid to flow in on...

READ MORE -

Such a scene often occurs during control valve selection meetings: The procurement manager asked: "Why not use this bal...

READ MORE

Key Considerations When Choosing Stop Valves for Industrial Systems

When selecting stop valves for industrial pipelines, the material, sealing performance, and compatibility with the medium are critical. For example, carbon steel stop valves are suitable for high-temperature and high-pressure environments, while stainless steel stop valves are preferred where corrosion resistance is essential. The operating frequency and medium cleanliness also influence the choice of valve type and sealing structure. Additionally, maintenance accessibility and cost efficiency should be weighed, especially in continuous production systems where downtime is costly.

Differences Between Stop Valves and Shut Off Valves in Functionality

Although “stop valves” and “shut off valves” are often used interchangeably, their functions differ slightly depending on system design. Stop valves are generally used for flow regulation and isolation, offering precise throttling control. Shut off valves, on the other hand, are typically used for complete closure to stop fluid transmission instantly, often in emergency or safety systems. In many cases, shut off valves feature faster actuation mechanisms or are integrated with automation controls for rapid response.

Advantages of Carbon Steel Stop Valves in High-Pressure Applications

Carbon steel stop valves provide superior strength and pressure resistance, making them ideal for heavy-duty operations. They are widely used in petrochemical, steam, and oil transmission lines due to their excellent mechanical performance. However, proper anti-corrosion treatment is essential when dealing with moisture or chemically active fluids. Common surface treatments include galvanizing, epoxy coating, or phosphate conversion layers to extend service life and maintain sealing integrity.

Why Stainless Steel Stop Valves Are Preferred for Corrosive Media

Stainless steel stop valves are highly resistant to oxidation, corrosion, and scaling, making them ideal for environments involving acids, alkalis, or saline solutions. Their durability and hygienic surface also make them suitable for food, pharmaceutical, and chemical industries. Compared to carbon steel, stainless steel valves require less frequent maintenance and exhibit stable sealing performance even after repeated operation cycles in aggressive conditions.

Common Failure Causes and Maintenance Tips for Stop Valves

Proper maintenance of stop valves significantly extends their operational life. Common failures include seat wear, packing leakage, corrosion pitting, and stem bending. To reduce these risks, routine inspection of sealing surfaces and lubrication of the stem threads are recommended. When valves are frequently operated under high temperature or high pressure, periodic pressure testing and surface cleaning are crucial to prevent material fatigue and ensure safety.

- Replace damaged seals promptly to avoid internal leakage.

- Clean valve internals regularly to remove sediment or chemical deposits.

- Avoid overtightening the handwheel, which can damage the seat surface.

- Check for corrosion on the bonnet and stem connection areas.

Comparative Table: Carbon Steel vs. Stainless Steel Stop Valves

| Feature | Carbon Steel Stop Valve | Stainless Steel Stop Valve |

| Pressure Resistance | Excellent, suitable for high pressure | Good, limited by temperature range |

| Corrosion Resistance | Moderate, needs coating or lining | Outstanding, ideal for corrosive fluids |

| Maintenance Frequency | Higher, due to rust prevention | Lower, minimal surface degradation |

| Cost | Economical | Higher initial investment |

Energy Efficiency Considerations in Valve Selection

Stop valves play an important role in reducing system energy loss. Poorly designed valves with uneven internal flow paths can create turbulence and increase pressure drop. Choosing valves with optimized body geometry and precise machining can reduce flow resistance. Furthermore, using automated shut off valves with precise control improves process efficiency, especially in systems with fluctuating flow demands or batch processing operations.

Trends in Smart Shut Off Valve Integration

Modern industrial systems increasingly adopt smart shut off valves equipped with sensors and control modules. These valves can monitor parameters such as temperature, pressure, and flow rate in real time. When abnormal conditions occur, the valve can automatically close to prevent accidents. Integration with IoT and SCADA systems allows remote diagnostics, predictive maintenance, and energy optimization, greatly enhancing operational reliability and safety.

Environmental Factors Affecting Valve Lifespan

Environmental conditions such as humidity, salinity, and temperature fluctuations have a significant effect on the longevity of stop valves. Outdoor installations near coastal regions often require stainless steel or coated carbon steel materials to resist salt spray corrosion. In high-temperature zones, thermal expansion must be considered, and flexible seals should be chosen to prevent leakage. Regular inspection and application of anti-rust coatings further enhance service life in challenging environments.

English

English Deutsch

Deutsch Indonesia

Indonesia