Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the cont...

READ MORE

Flow Control Valves Suppliers

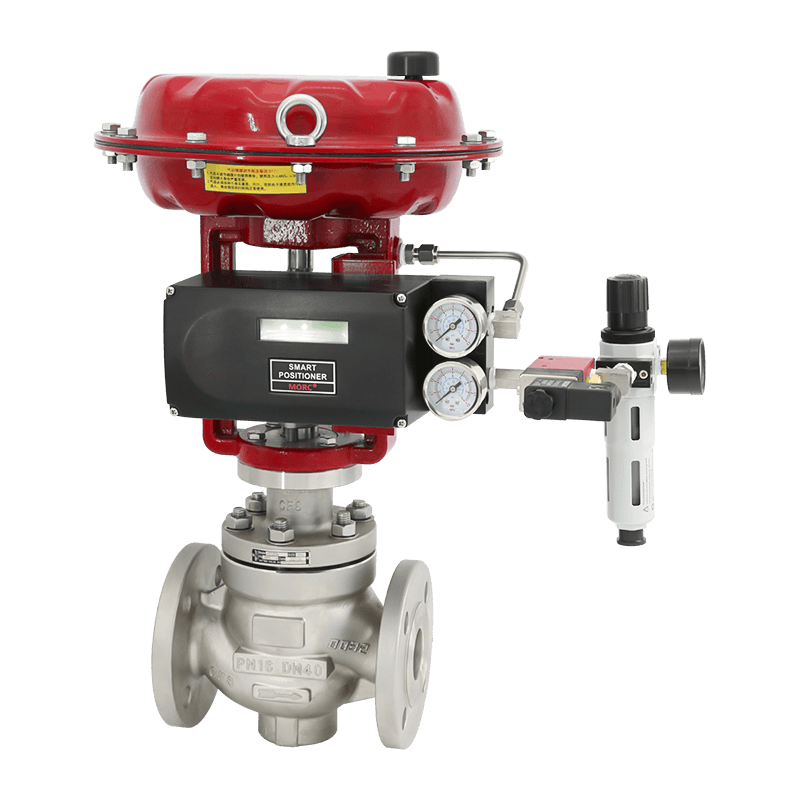

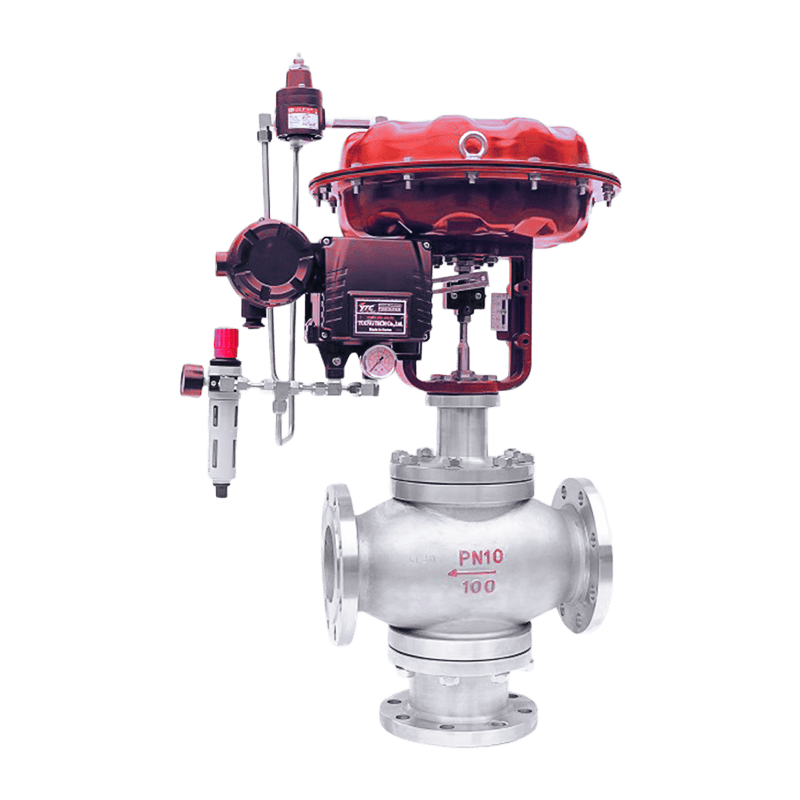

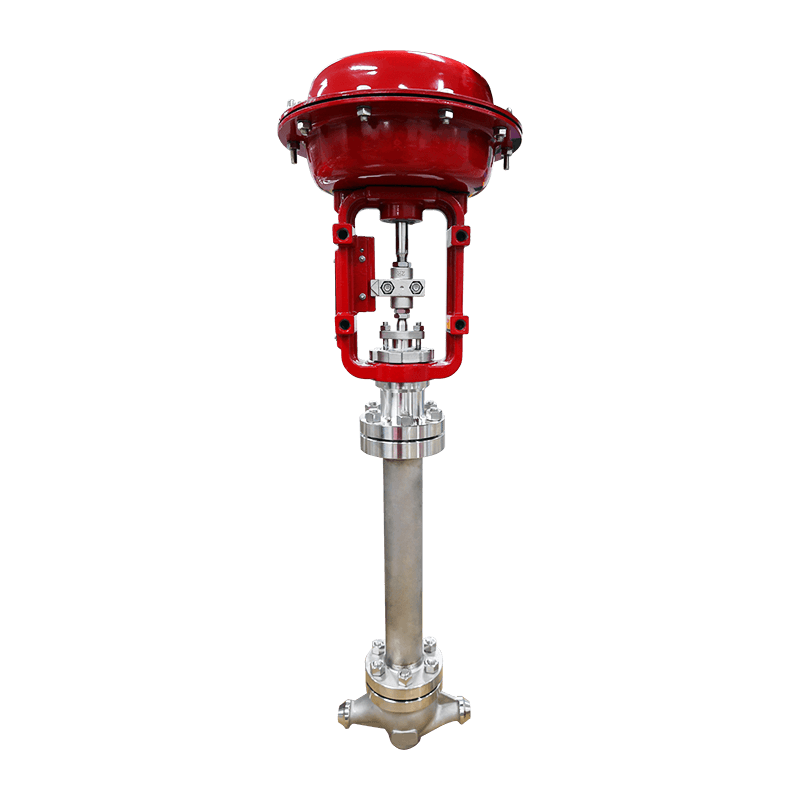

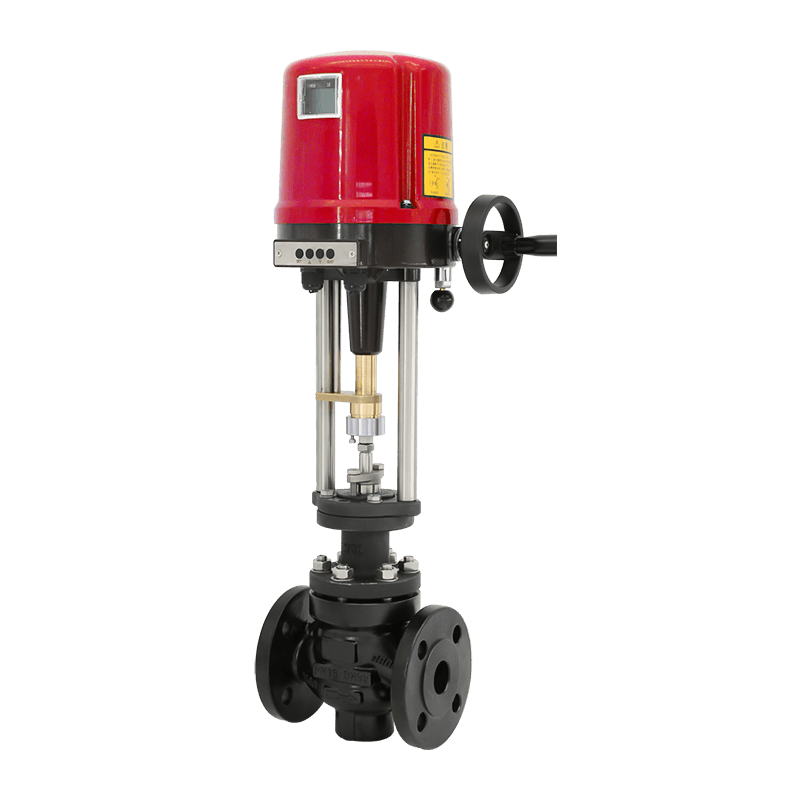

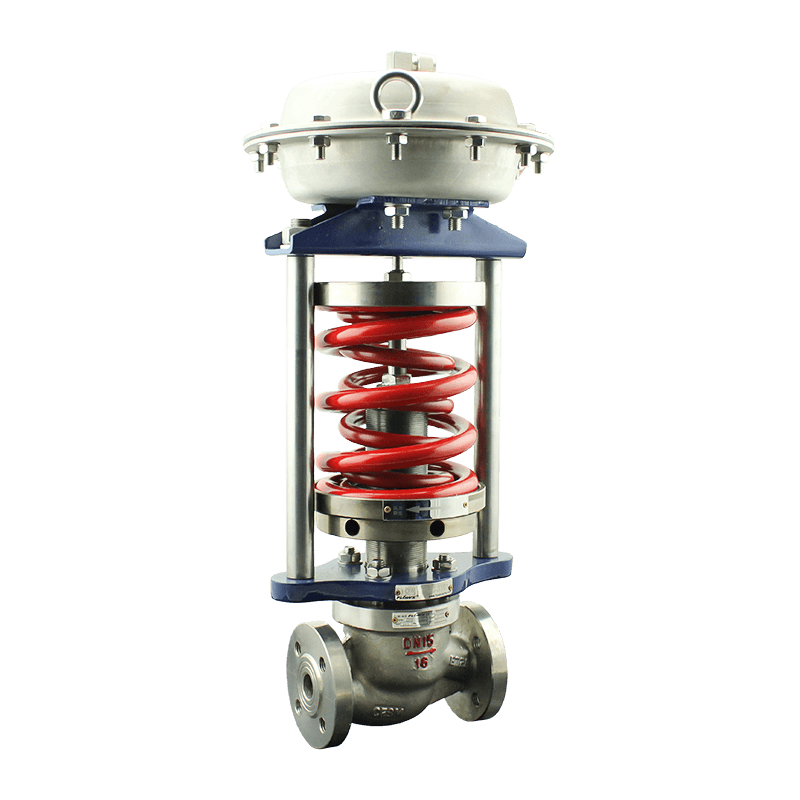

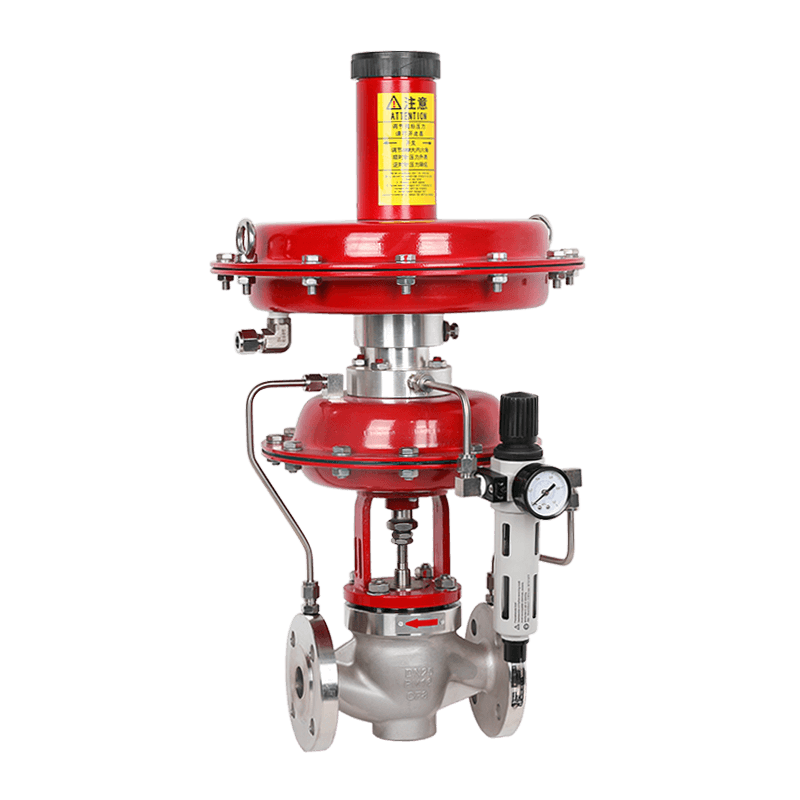

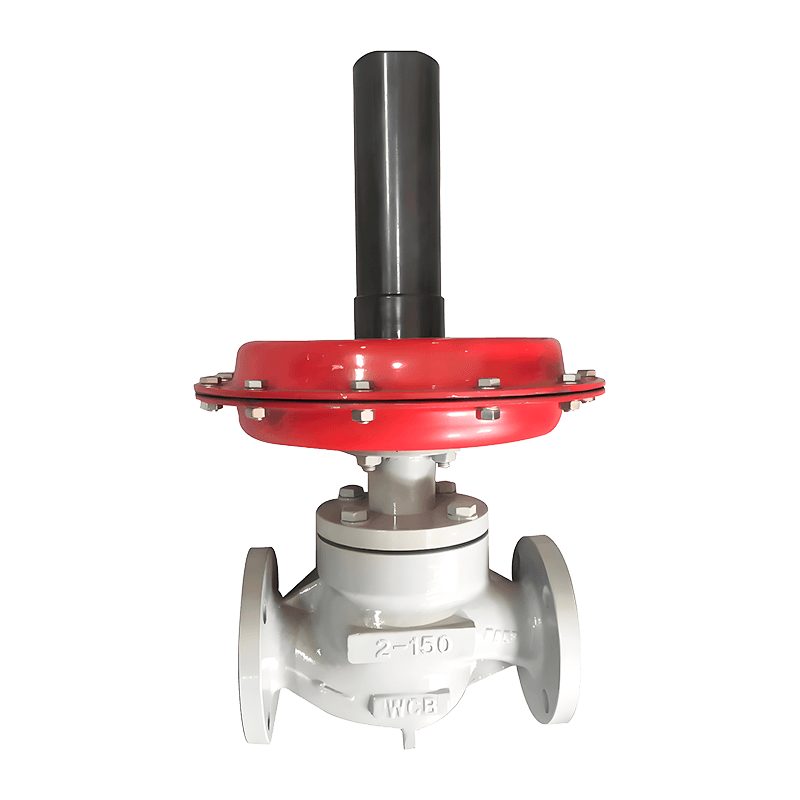

VATTEN offers a comprehensive range of control valves designed to meet the specific needs of your project. Whether you require manual, pneumatic, or self-standing options, our products are tailored to provide the most efficient and precise flow control solutions. Each valve is crafted with the highest quality materials, ensuring long-term performance and reliability in various industrial applications.

Our control valves are equipped with advanced components, including top-tier positioners and electric actuators, which guarantee accurate positioning and seamless integration with your existing systems. This combination of high-quality parts ensures optimal control and smooth operation, even in demanding environments.

At VATTEN, we are committed to providing versatile solutions that enhance the functionality and performance of your projects, making precise flow control more accessible and effective than ever before.

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

As Flow Control Valves Suppliers and Flow Control Valves Factory, the Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. Provide Custom Flow Control Valves. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

-

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow co...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatic...

READ MORE -

Key Conclusion: Why Check Valves Are Essential in Fluid Systems Check valves are installed to allow fluid to flow in on...

READ MORE -

Such a scene often occurs during control valve selection meetings: The procurement manager asked: "Why not use this bal...

READ MORE

Optimizing System Performance with Electric and Pneumatic Valves

Integrating VATTEN electric and pneumatic flow control valves into existing industrial systems enhances precision and efficiency. Electric actuators provide high-resolution control over valve positions, allowing automated adjustments in real time. Pneumatic actuators offer rapid response times suitable for high-speed process requirements. Proper integration ensures that flow control is maintained consistently, reducing energy consumption and minimizing process variability.

Synchronization Techniques for Multi-Valve Systems

When multiple valves are deployed in a single production line, synchronization becomes critical. VATTEN valves equipped with advanced digital positioners can communicate with central control systems to coordinate opening and closing sequences. This coordination prevents pressure surges, maintains consistent flow rates, and ensures safe operation in sensitive processes such as chemical dosing or pharmaceutical production.

Integration Strategies for Diverse Industrial Applications

Different industries require customized approaches for flow control valve integration. In water treatment plants, electric actuators enable precise regulation of water flow under varying demand conditions, while pneumatic valves handle rapid emergency shutoffs. In food processing, hygienic design combined with automated valve control ensures consistent product quality and reduces contamination risk. Selecting the correct combination of valve type and actuator is essential for optimal process control.

Practical Guidelines for Implementation

- Evaluate process flow requirements and peak load conditions before selecting valve types

- Ensure actuator compatibility with existing control systems and protocols

- Implement predictive maintenance and remote monitoring to maintain seamless operation

- Calibrate valves periodically to account for environmental or material-specific factors

Performance Comparison Between Electric and Pneumatic Actuators

| Feature | Electric Actuators | Pneumatic Actuators |

| Response Time | High precision, moderate speed | Fast response, suitable for emergency actions |

| Control Accuracy | Extremely precise positioning | Moderate accuracy, best for on/off or throttling tasks |

| Maintenance | Lower mechanical wear, requires electrical inspection | More frequent mechanical checks, simple replacement |

| Energy Consumption | Dependent on control cycles, efficient in automated systems | Compressed air consumption can be high under frequent operation |

Ensuring Reliability Through System Integration

Achieving seamless integration requires careful planning of control architecture and feedback mechanisms. Combining VATTEN valves with SCADA systems or PLC-based automation provides real-time monitoring and adjustment capabilities. This approach minimizes downtime, prevents pressure fluctuations, and enhances safety by ensuring that each valve operates within its specified limits. Regular integration testing helps identify potential conflicts and maintains consistent operational performance.

English

English Deutsch

Deutsch Indonesia

Indonesia