Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the control valve cannot stably maintain an appropriate position to sustain the predetermined proc...

READ MORE

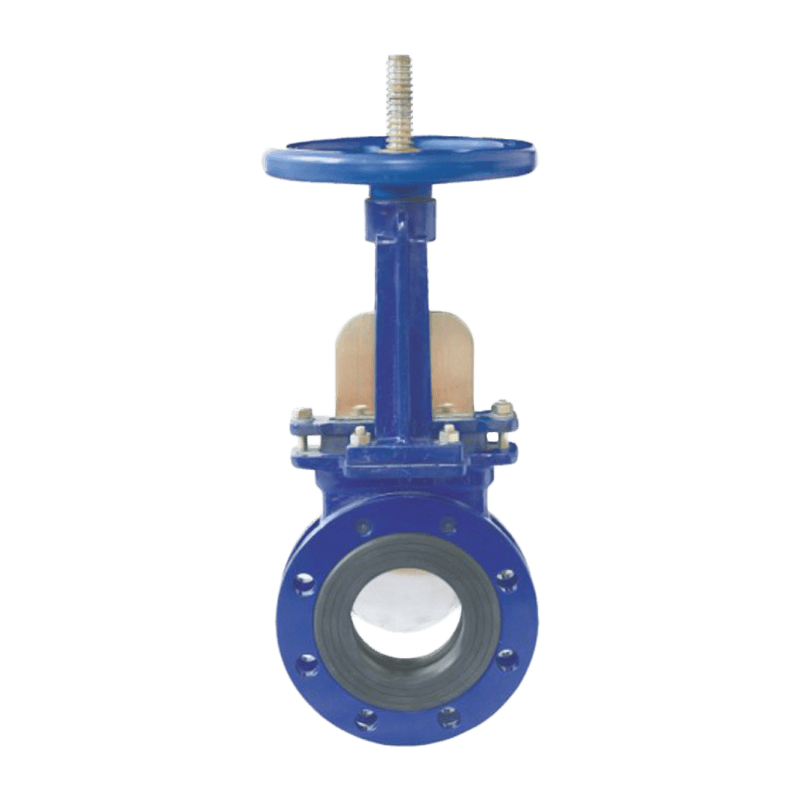

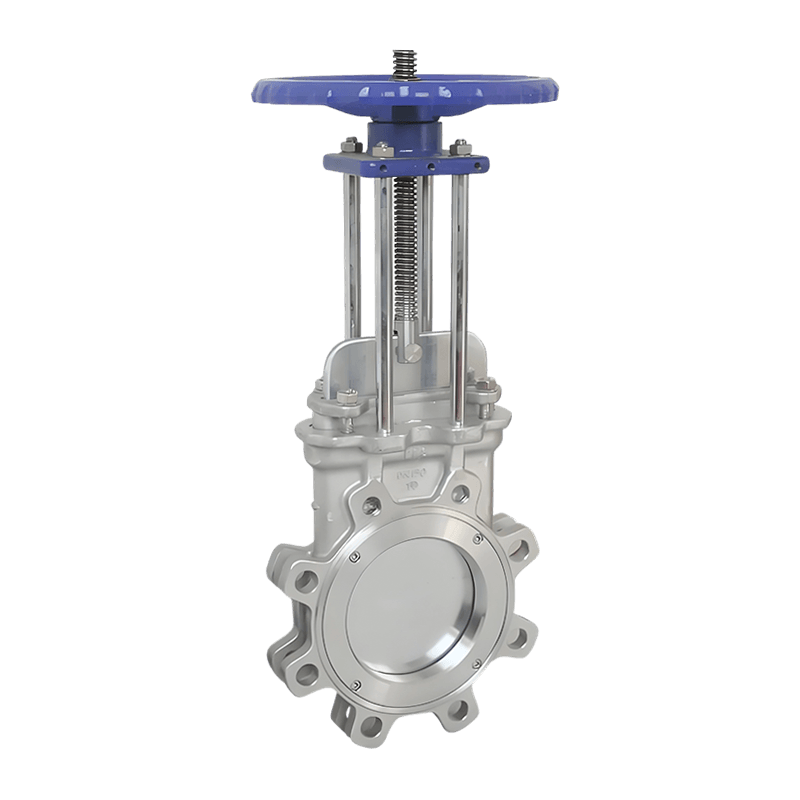

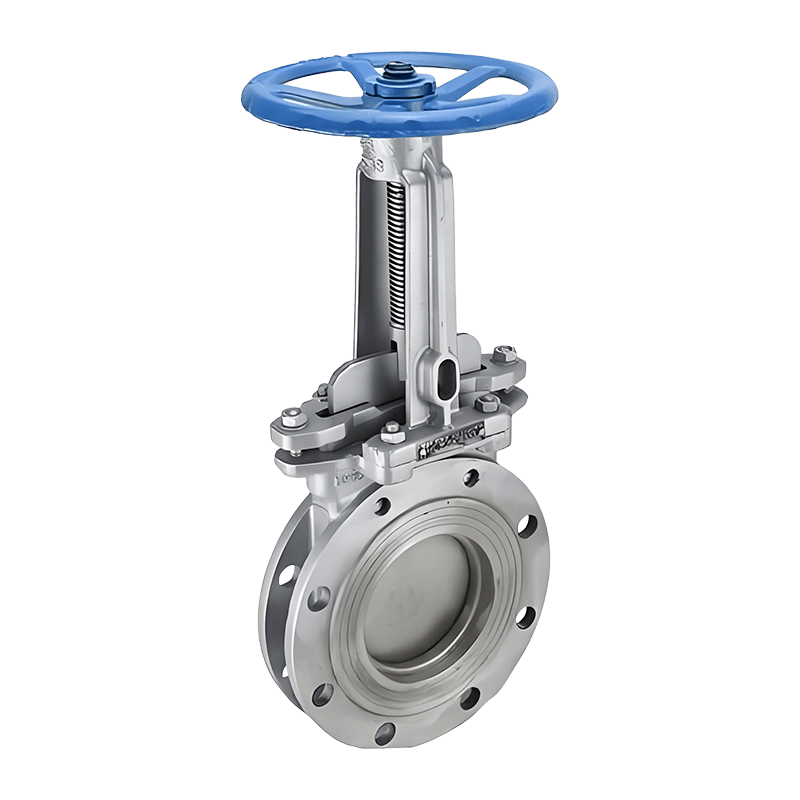

Manual Knife Gate Valves Manufacturers

VATTEN manual knife gate valves perform exceptionally well in handling media such as sludge and powders. The design features a powerful cutting force, allowing it to efficiently handle thick and viscous materials, ensuring the valve operates smoothly and securely when opening and closing. The valve plate is made of solid materials, which guarantees excellent sealing and performance even after long-term use.

Additionally, the wear resistance of the VATTEN manual knife gate valve is a major advantage. The body and valve plate are made from specially treated materials, giving the valve remarkable abrasion resistance when dealing with high-wear media. Even in extended usage, the wear remains minimal, extending the valve's lifespan and reducing maintenance costs.

The superior performance of the VATTEN manual knife gate valve makes it widely used in industries such as wastewater treatment, mining, and papermaking, particularly in environments where frequent valve operation is required, ensuring smooth and safe operation.

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

As Manual Knife Gate Valves Manufacturers and Manual Knife Gate Valves Company, the Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. Provide Custom Manual Knife Gate Valves. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

-

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow controlled release of bulk solids, slurries, or liquids by gravity. They are a critical comp...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatically using an electric actuator that adjusts valve position based on control signals. They...

READ MORE -

Key Conclusion: Why Check Valves Are Essential in Fluid Systems Check valves are installed to allow fluid to flow in only one direction and automatically prevent reverse flow without manual intervention. Their...

READ MORE

How Effective Are Vatten Valve Group’s Manual Knife Gate Valves at Preventing Clogging in Slurry Applications?

Introduction to Vatten Valve Group

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. With deep technological expertise, Vatten provides innovative valve solutions and professional technical support to industries including energy, chemical, water treatment, pharmaceutical, and food processing.

As Manual Knife Gate Valve manufacturers, Vatten Valve Group operates four advanced production bases in Shanghai, Tianjin, Lishui, and Jiaxing, China. Branch offices in the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia further enhance the company’s global service network. The Indonesian office, in particular, strengthens service capabilities across Southeast Asia, ensuring timely and efficient technical support for local partners and clients.

Rooted in the German tradition of precision engineering, Vatten Valve Group adheres to international quality standards while offering custom Manual Knife Gate Valves designed for demanding industrial environments.

Understanding Slurry Applications and Clogging Challenges

Slurry media, common in wastewater treatment, mining, and pulp and paper industries, often contains high concentrations of solids such as sludge, powders, and fibrous materials. These characteristics make valves prone to clogging, which can disrupt operations, increase maintenance needs, and reduce process efficiency.

In such environments, valve design plays a critical role in maintaining consistent flow and preventing blockages. Factors like the cutting force of the valve, the smoothness of the flow path, and the materials used in construction determine whether a valve can reliably handle viscous or high-solid-content media.

How Vatten Manual Knife Gate Valves Prevent Clogging

Vatten manual knife gate valves are specifically engineered to address the challenges of handling thick, abrasive, and high-solid-content media. Key design features that prevent clogging include:

Robust Cutting Force

The knife-edge design ensures the valve can slice through fibrous, thick, or viscous materials during operation. This cutting capability reduces the risk of material accumulation at the sealing surfaces, keeping the valve pathway clear.

High-Quality Valve Plate Materials

The valve plate is made from solid, wear-resistant materials. This not only ensures excellent sealing but also prevents the gradual buildup of media deposits that can lead to clogging.

Abrasion-Resistant Construction

Both the valve body and plate are treated for exceptional wear resistance, allowing them to withstand abrasive slurries over long periods. Minimal wear prevents gaps or rough surfaces where particles could lodge and cause blockages.

Smooth and Secure Operation

The precision-engineered sliding mechanism ensures the valve opens and closes reliably even under heavy-duty conditions, preventing material from sticking and accumulating inside the valve.

Industrial Applications and Benefits

Vatten manual knife gate valves are widely used in industries where frequent valve operation is required, such as:

- Wastewater Treatment: Handles sludge and fibrous media with minimal maintenance.

- Mining: Manages abrasive slurry flows while maintaining operational efficiency.

- Papermaking: Cuts through pulp and fibrous materials without clogging.

By minimizing clogging, these valves not only improve operational efficiency but also extend equipment lifespan, reduce maintenance costs, and ensure safer plant operations.

Customization and Global Support

Vatten Valve Group also provides custom manual knife gate valves to meet unique industrial requirements, ensuring optimal performance even in highly specialized slurry applications. With global branch offices and a strong Southeast Asian presence, Vatten delivers responsive technical support, helping clients select, install, and maintain the most effective solutions for their processes.

Conclusion

Vatten Valve Group’s manual knife gate valves are highly effective at preventing clogging in slurry applications. Their robust cutting force, abrasion-resistant materials, and precision-engineered design allow them to handle thick, fibrous, and high-solid-content media reliably. Coupled with Vatten’s global expertise and customized solutions, these valves offer industries a dependable choice for maintaining uninterrupted operations and reducing maintenance costs.

English

English Deutsch

Deutsch Indonesia

Indonesia