Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the cont...

READ MORE

Valve Accessories Suppliers

VATTEN offers a versatile range of valve accessories that complement our extensive valve products. These accessories are designed to enhance system performance, improve control, and ensure reliable operation in various industrial applications.

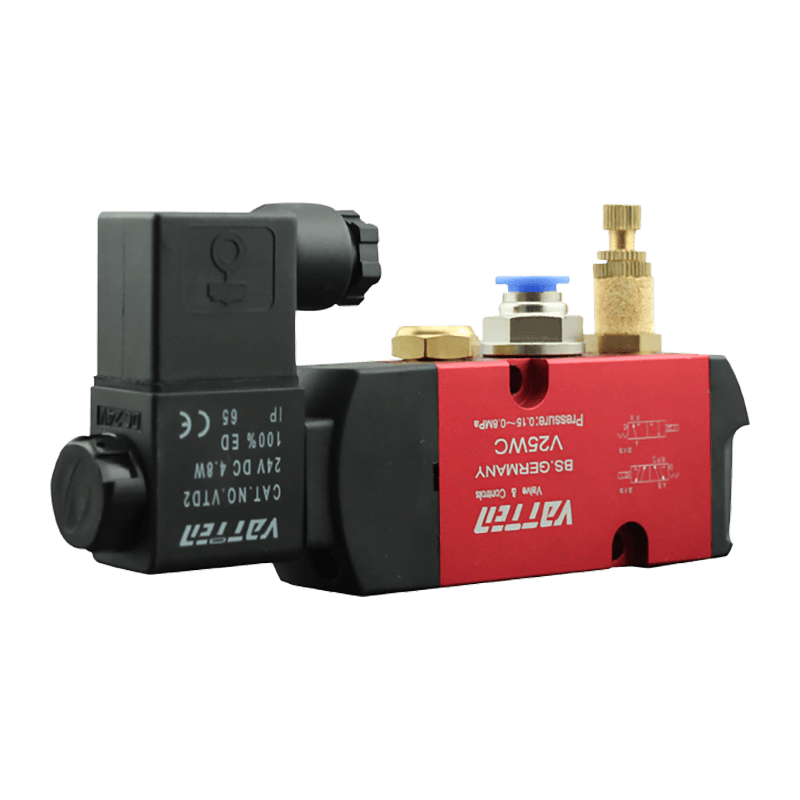

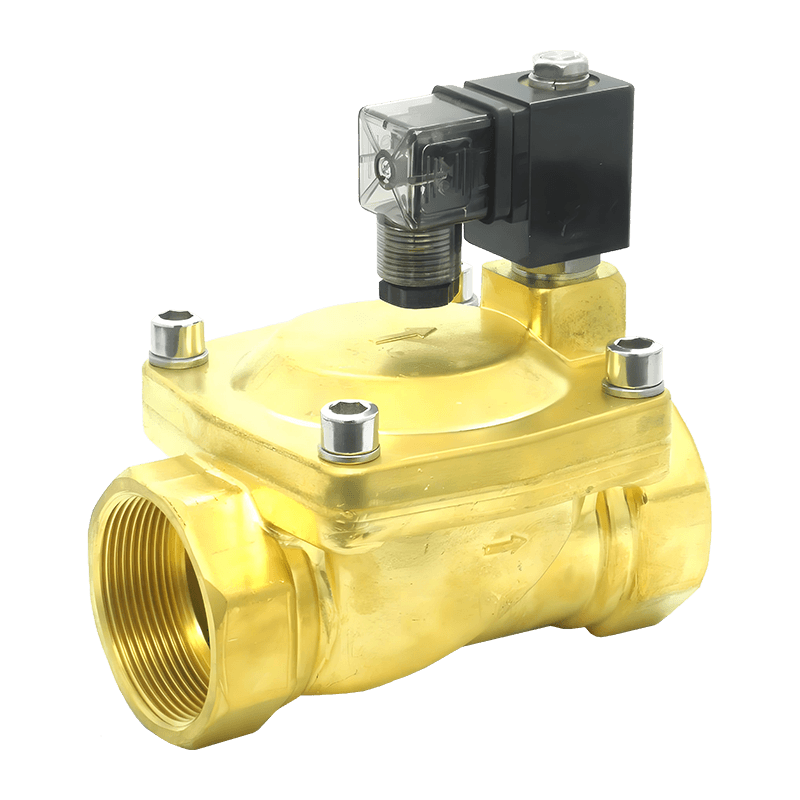

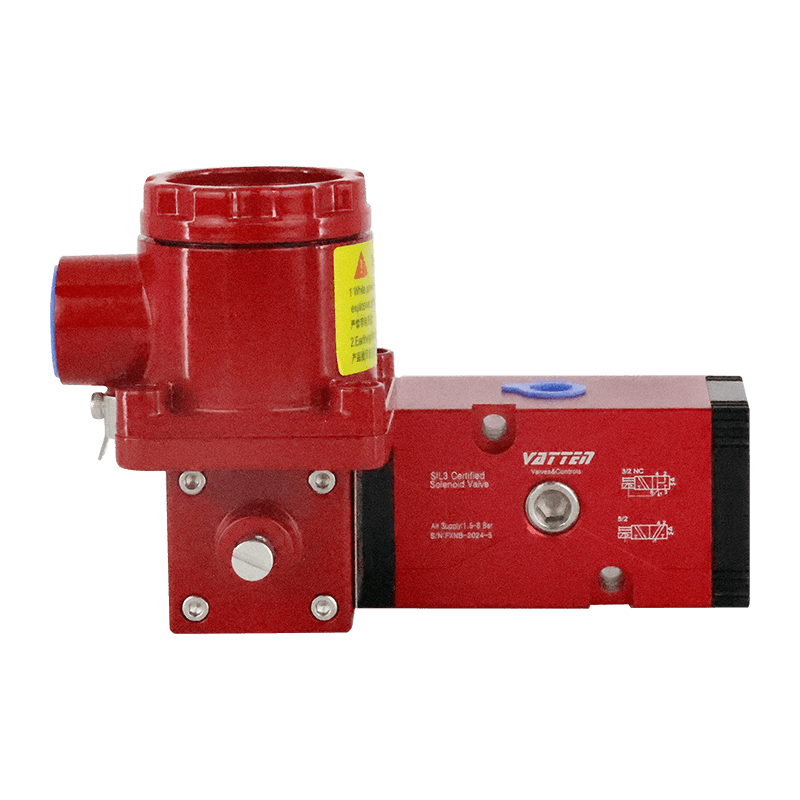

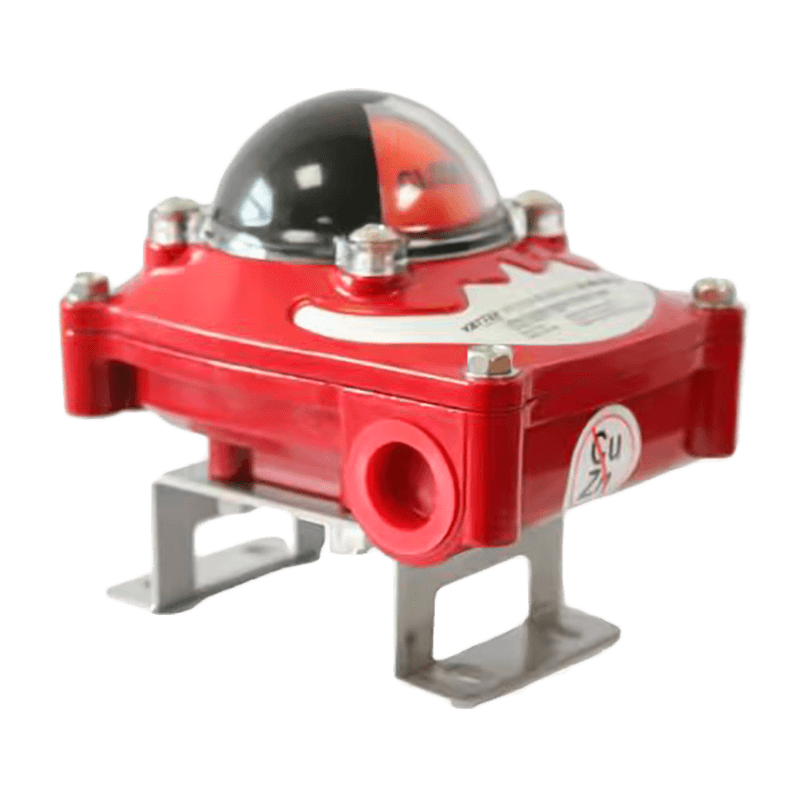

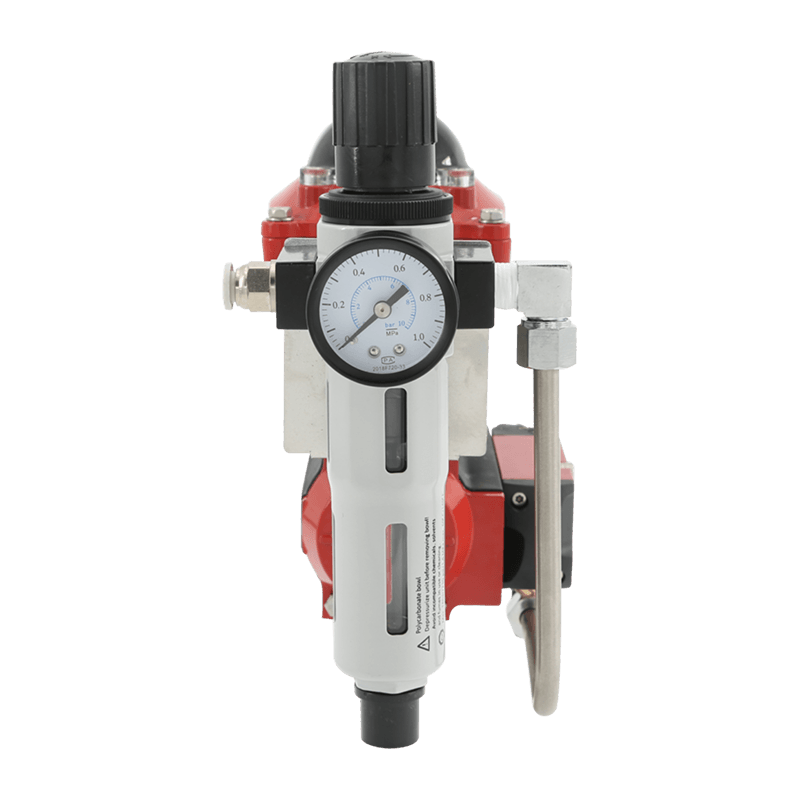

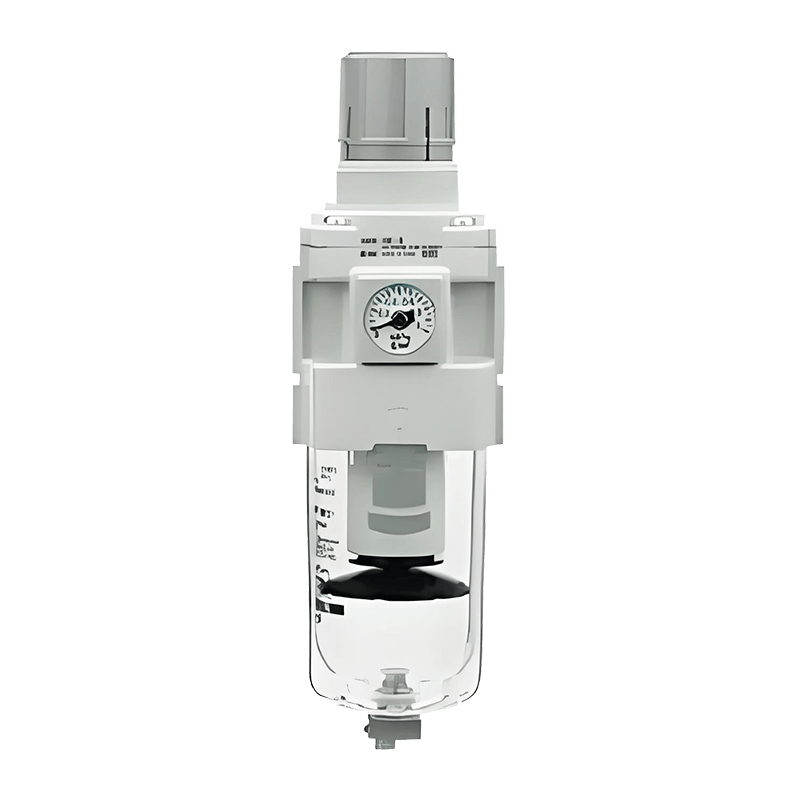

Our solenoid valves are built for precise and efficient flow control, enabling seamless integration into automated systems. The valve limit switches provide critical feedback on valve positions, ensuring accuracy and preventing operational errors. The filter pressure reducing valves effectively manage pressure and filtration, enhancing the longevity and reliability of valve systems.

The valve positioners offer fine-tuned control over valve settings, allowing for optimal performance in demanding environments. Meanwhile, the valve clutches ensure smooth operation, offering protection for valve actuators and minimizing wear and tear.

Together, these accessories provide a comprehensive solution that guarantees operational efficiency and contributes to the durability of your valve systems.

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

As Valve Accessories Suppliers and Valve Accessories Factory, the Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. Provide Custom Valve Accessories. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

-

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow co...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatic...

READ MORE -

Key Conclusion: Why Check Valves Are Essential in Fluid Systems Check valves are installed to allow fluid to flow in on...

READ MORE -

Such a scene often occurs during control valve selection meetings: The procurement manager asked: "Why not use this bal...

READ MORE

What Are the Most Common Types of Valve Accessories?

Valves are integral components in various industrial systems, providing essential flow control and regulation of fluids or gases. However, the valve itself is often not enough to ensure optimal performance. To maximize efficiency, reliability, and safety, a variety of accessories are employed in conjunction with valves. These accessories enhance the functionality of the valves, allowing for better control, automation, and system integration. In this article, we will explore the most common types of valve accessories and their roles in industrial applications.

What Are Valve Accessories?

Valve accessories are supplementary components that enhance the operation of valves by adding functionality, improving control, and ensuring safety. These accessories work together with the valve to optimize its performance, providing automated operation, precise monitoring, and real-time feedback. Some accessories are required for particular types of valves, while others are used to upgrade or modify existing systems. Common valve accessories include solenoid valves, limit switches, actuators, positioners, and explosion-proof devices. Let’s delve into the most widely used types of valve accessories.

1. Solenoid Valves

Solenoid valves are one of the most widely used valve accessories for controlling the flow of liquids or gases in automated systems. These valves are electrically operated and use a solenoid coil to control valve opening and closing. The solenoid valve's primary function is to regulate the flow of fluids within a piping system by opening or closing the valve based on an electrical signal.

There are different types of solenoid valves, including:

- Pipe-Connected Solenoid Valve: These are solenoid valves that are directly connected to a pipeline. They are commonly used in fluid control applications, such as water, air, or steam systems.

- Explosion-Proof Solenoid Valve: Designed for hazardous environments, explosion-proof solenoid valves are built with rugged enclosures to prevent sparks or heat from causing explosions. They are typically used in industries like oil and gas, mining, and chemical processing.

Solenoid valves are essential for industries that require fast, reliable, and automated control over fluid systems. They are used in applications ranging from HVAC systems to food processing and chemical manufacturing.

2. Valve Limit Switches

Limit switches are sensors used to detect the position of a valve. They are commonly installed on valves to provide feedback to control systems, indicating whether the valve is fully open, closed, or in an intermediate position. The purpose of the valve limit switch is to prevent over-travel and ensure precise positioning, which is essential for accurate flow control.

There are two main types of valve limit switches:

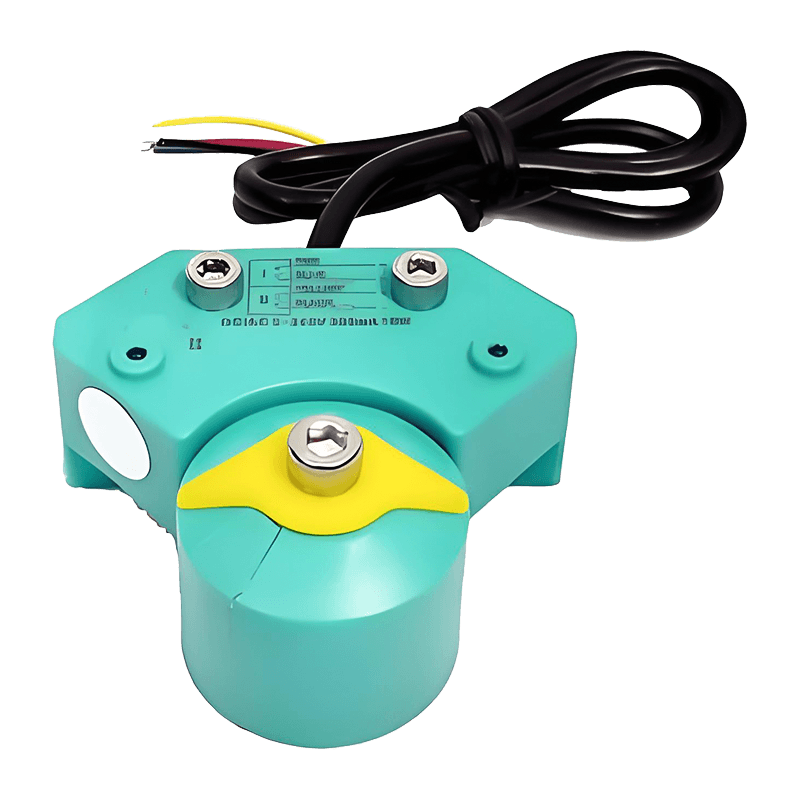

- Inductive Valve Limit Switch: These switches use inductive proximity sensors to detect the position of the valve stem or actuator. They are commonly used for applications that require non-contact sensing and are suitable for both manual and automated valve systems.

- Explosion-Proof Valve Limit Switch: These limit switches are designed for hazardous environments where sparks or heat could trigger an explosion. They are equipped with explosion-proof enclosures and are typically used in industries such as oil and gas, chemical manufacturing, and mining.

Valve limit switches provide real-time information to operators, enhancing the control and safety of valve operations. They ensure that the valve's position is accurately communicated to the control system, allowing for better regulation of the flow of fluids.

3. Actuators

Actuators are mechanical devices that automate the movement of valves. They are essential in applications that require automated valve operation without human intervention. Actuators can be powered by electricity, pneumatic systems, or hydraulic pressure. Their primary function is to convert energy into mechanical motion to control the valve’s opening and closing.

Types of actuators include:

- Electric Actuators: These actuators use an electric motor to move the valve. Electric actuators are often used in applications where precise control and automation are required. They are commonly used in industries like water treatment, chemical processing, and HVAC.

- Pneumatic Actuators: Powered by compressed air, pneumatic actuators are widely used in systems that require quick and efficient operation. They are ideal for high-cycle applications and are commonly used in the oil and gas, food processing, and pharmaceutical industries.

- Hydraulic Actuators: Hydraulic actuators use pressurized fluid to generate force and are typically used in high-torque applications where substantial force is required to operate large valves or systems with high-pressure conditions.

Actuators help in reducing manual intervention and ensure that valves are opened or closed as per the system’s requirements. This increases efficiency and reduces the risk of human error in automated systems.

4. Valve Positioners

Valve positioners are accessories used to control and monitor the position of a valve actuator. They ensure that the actuator is accurately positioned according to the signal received from the control system. Positioners are used in conjunction with actuators to provide fine-tuned control over valve movement, especially in systems requiring precise flow regulation.

Positioners are typically used in applications where the valve needs to be adjusted continuously based on the process conditions, such as in chemical plants, water treatment facilities, and energy production plants. By optimizing the actuator’s movement, valve positioners help improve process efficiency and ensure accurate control of fluid or gas flow.

5. Other Valve Accessories

In addition to the common valve accessories mentioned above, there are other components that can enhance valve performance, safety, and control. These include:

- Valve Dampers: These devices are used to reduce the impact of valve operation and minimize vibration, which can lead to wear and tear. Valve dampers are often used in high-pressure systems where sudden valve movements could result in system instability.

- Actuator Mounting Brackets: These brackets are used to securely attach the actuator to the valve body, ensuring that the actuator performs optimally and the valve remains properly aligned.

- Valve End Connectors: These connectors provide a secure, leak-proof connection between the valve and the pipeline, ensuring that the system operates without leaks.

These additional accessories help maintain the valve system's integrity, improve safety, and reduce maintenance costs by ensuring smooth operation and minimizing the risk of failure.

Conclusion

Valve accessories play a crucial role in enhancing the functionality, performance, and safety of valve systems in industrial applications. From solenoid valves to limit switches, actuators, and positioners, these accessories provide automation, precise control, and real-time feedback that optimize valve operations. By integrating these accessories into valve systems, industries can achieve greater efficiency, safety, and reliability in their operations.

Choosing the right valve accessories depends on the specific needs of the application, including the type of fluid or gas being controlled, environmental conditions, and the level of automation required. With the right combination of valve and accessories, industries can ensure long-lasting and efficient valve performance, reducing downtime and increasing system reliability.

Furthermore, the integration of modern valve accessories, such as explosion-proof components and automated control systems, has enabled industries to operate in more demanding and hazardous environments. By using accessories like explosion-proof solenoid valves and limit switches, businesses can ensure that their valve systems not only function efficiently but also comply with safety standards and regulatory requirements. This is particularly crucial in sectors such as oil and gas, chemical manufacturing, and mining, where safety is paramount.

The selection and maintenance of these valve accessories are just as important as the valves themselves. Regular checks on the performance of solenoid valves, actuators, and limit switches, along with proper installation of positioners and dampers, can significantly extend the lifespan of the entire valve system. This proactive approach to maintenance can prevent costly failures and unplanned downtime, leading to improved productivity and a safer working environment.

In conclusion, valve accessories are not merely supplementary; they are essential components that ensure the efficient, reliable, and safe operation of valve systems. By understanding the role of these accessories and incorporating them into industrial processes, companies can enhance the performance, safety, and longevity of their valve systems, ultimately contributing to smoother and more productive operations across a wide range of industries.

English

English Deutsch

Deutsch Indonesia

Indonesia