Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the cont...

READ MORE

Reaction Vessel Valves Manufacturers

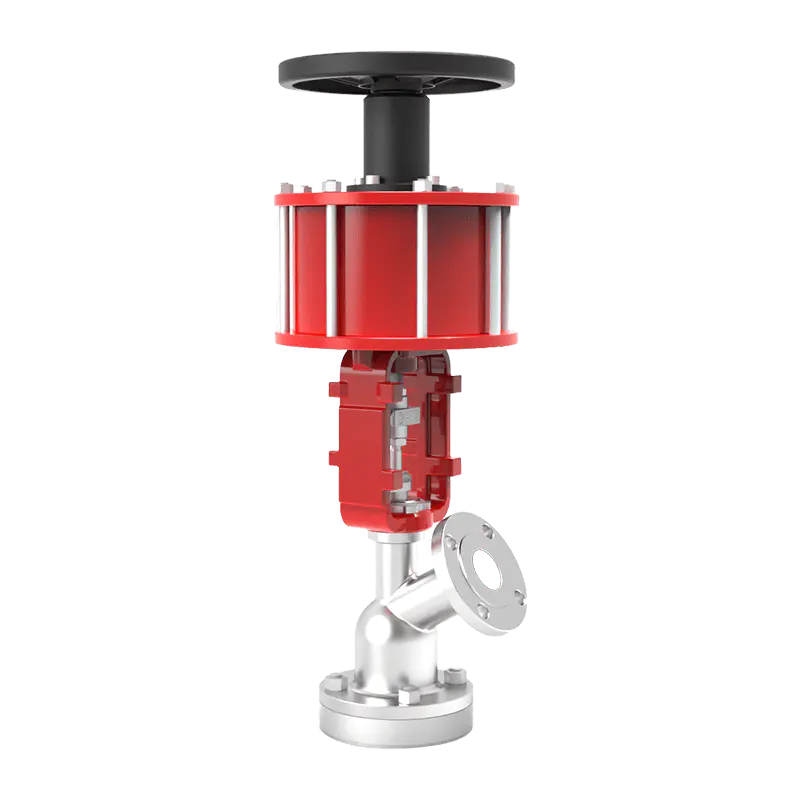

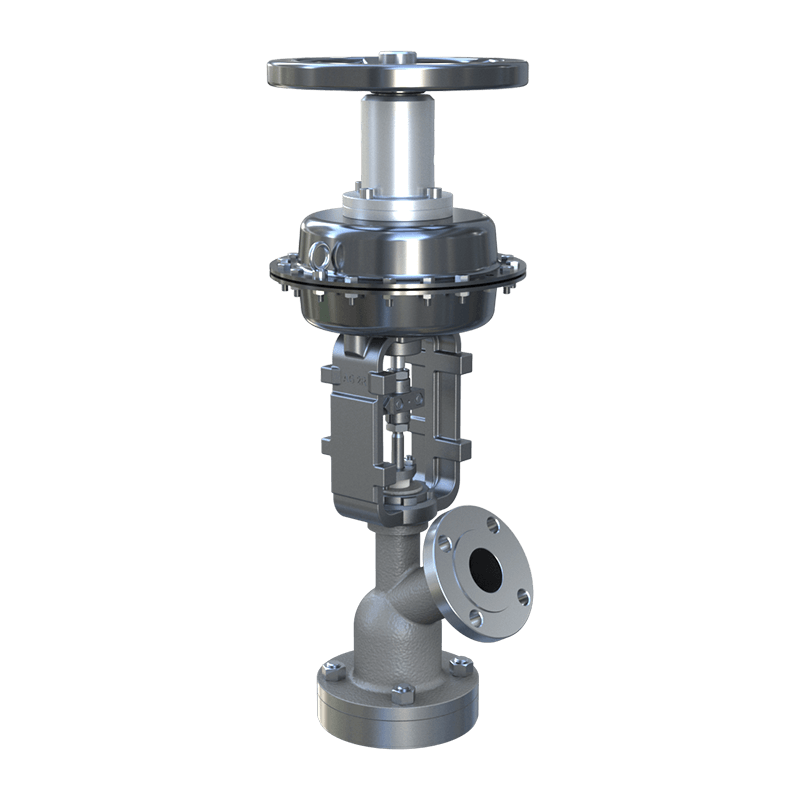

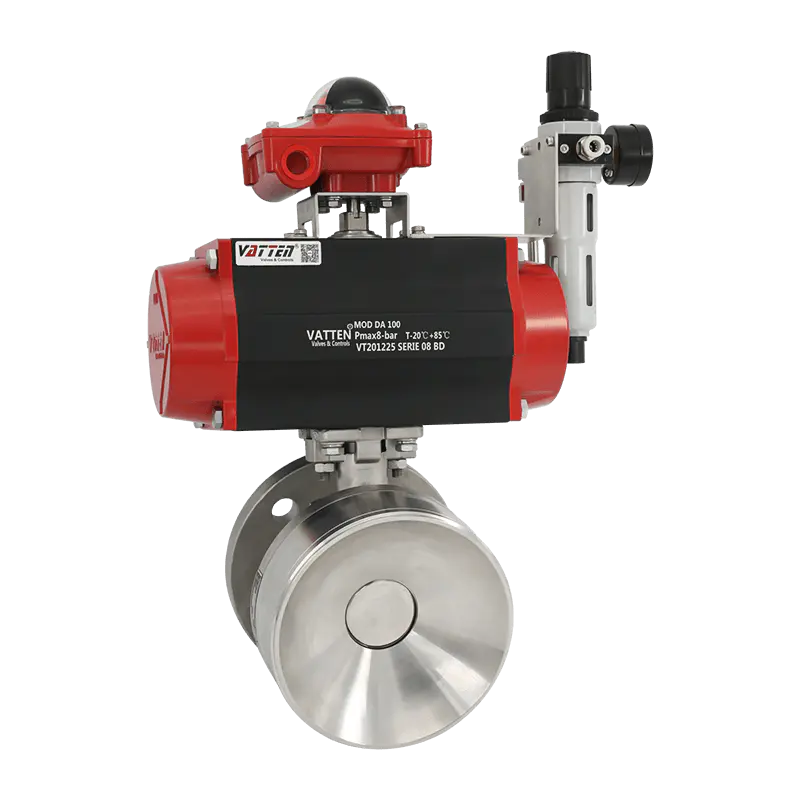

VATTEN's product range for reaction vessels includes specialized valves designed to meet the demanding needs of industrial processes involving various media. Among these, we offer pneumatic, electric, and manual baiting valves, all engineered to ensure efficient discharge in reaction vessels. These valves are crucial for controlling the release of substances and preventing operational interruptions in complex systems.

Our bottom discharge valves are specifically crafted for reaction vessels containing challenging media such as pigments, water-based coatings, and resins. With precise construction, these valves guarantee smooth flow and high performance, even with thick or viscous materials. Their robust design ensures reliability in demanding environments, contributing to the overall efficiency and safety of industrial processes.

Whether you require a manual, pneumatic, or electric solution, VATTEN's special valves provide optimal performance and durability, making them the ideal choice for industries involved in coating, resin production, and other chemical processes.

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

As Reaction Vessel Valves Manufacturers and Reaction Vessel Drain Valves Suppliers, the Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. Provide Custom Valves for Reaction Vessels. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

-

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow co...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatic...

READ MORE -

Key Conclusion: Why Check Valves Are Essential in Fluid Systems Check valves are installed to allow fluid to flow in on...

READ MORE -

Such a scene often occurs during control valve selection meetings: The procurement manager asked: "Why not use this bal...

READ MORE

The “Critical Guardians” of Reaction Vessels: Professional Analysis of Reactor Valve Technology

The Importance of Reactor Valves and the Trend Towards Automation

In fields such as petrochemicals, fine chemicals, pharmaceutical engineering (APIs), and food science, the Reaction Vessel (Reactor) is a core piece of equipment for essential processes like chemical reactions, mixing, dissolution, and crystallization. Reaction Vessel Valves are the “critical guardians” that connect the process system, control material flow, and ensure reaction safety. Their performance directly affects product quality, production efficiency, and operational safety.

Reactor valves must not only withstand demanding conditions of temperature, pressure, and media corrosion but also solve process-specific challenges related to “Dead Space” and complete “Draining,” which primarily distinguishes them from standard pipeline valves.

Vatten Valve Group specializes in this critical area. This globally renowned industrial automation valve enterprise, originating from Saarland, Germany, focuses on the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing, empowering clients to tackle complex industrial fluid control challenges.

I. Classification, Function, and Vatten’s Technical Expertise

Valves on a reaction vessel are classified by function and installation location. The Reaction Vessel Drain Valve is the most critical component, ensuring the thorough, dead-space-free discharge of material.

1. Reaction Vessel Drain Valves (Bottom Outlet Valves)

These valves are designed to eliminate “dead space” and prevent cross-contamination.

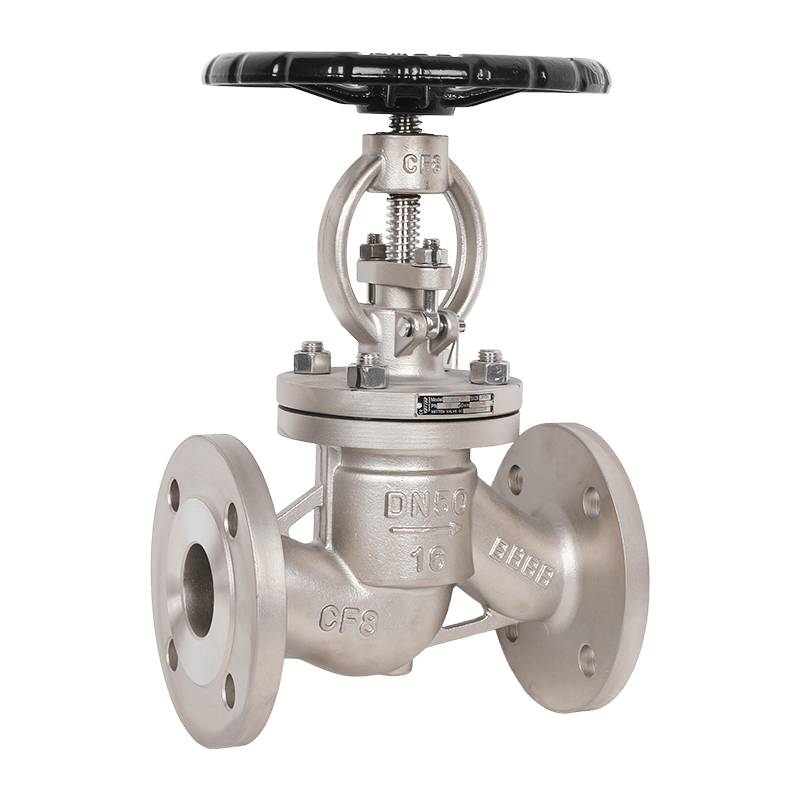

2. Inlet/Outlet Valves and Automatic Control

Precise control during the feeding and discharging processes is key to product quality. Vatten Valve Group plays a significant role in this area. Rooted in the German tradition of precision manufacturing, the company strictly adheres to international quality standards while maintaining its focus on automatic control valves. Its high-precision automatic control ball valves and regulating valves are ideal choices for the accurate metering of feed material and the control of fluid flow within jacketed temperature control systems.

II. Professional Selection Criteria: Global Service for Harsh Conditions

The professional selection of valves for reaction vessels is a complex, multi-factor process that must fully consider corrosion resistance, sealing performance, and extreme temperature and pressure conditions. For highly corrosive media, materials like Nickel-based alloys, PTFE/PFA-lined, or Glass-lined valves are required, while hazardous or high-value media demand zero-leakage through structures like bellows seals.

To better serve the global demand for high-quality valves, Vatten Valve Group maintains a strategic worldwide presence:

- Manufacturing Bases: The Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China, ensuring strong production capacity and a flexible supply chain.

- Global Network: To better serve international markets, Vatten has established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia.

- Serving Southeast Asia: The establishment of our Indonesian office is particularly significant, as it substantially enhances our service capabilities in the rapidly growing Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Vatten Valve Group is committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions.

III. Key Technical Details of Drain Valves and the Future of Automation

A professional reaction vessel drain valves should feature a dead-space-free design, jacketed insulation, and optional in-line temperature sensing. By integrating Vatten’s automation strengths, a safer and more efficient reaction process can be achieved:

- Integrated Automation: Through Vatten’s automatic control valve and actuator technology, bottom outlet valves can be easily integrated into a DCS (Distributed Control System) or PLC, enabling remote, precise, and interlocked safety discharge.

- Commitment to Innovation: Vatten Valve Group is committed to continuous innovation, combining advanced automation control technology with the specific demands of reaction vessels, thereby providing fluid control products that meet the highest standards, and supporting industrial automation and process optimization.

Vatten Valve Group, rooted in German rigor and technology, provides advanced automation valve solutions globally, ensuring the stable and efficient operation of critical industrial equipment like reaction vessels.

English

English Deutsch

Deutsch Indonesia

Indonesia