Control valve vibration refers to the rapid opening and closing of the valve during operation, indicating that the cont...

READ MORE

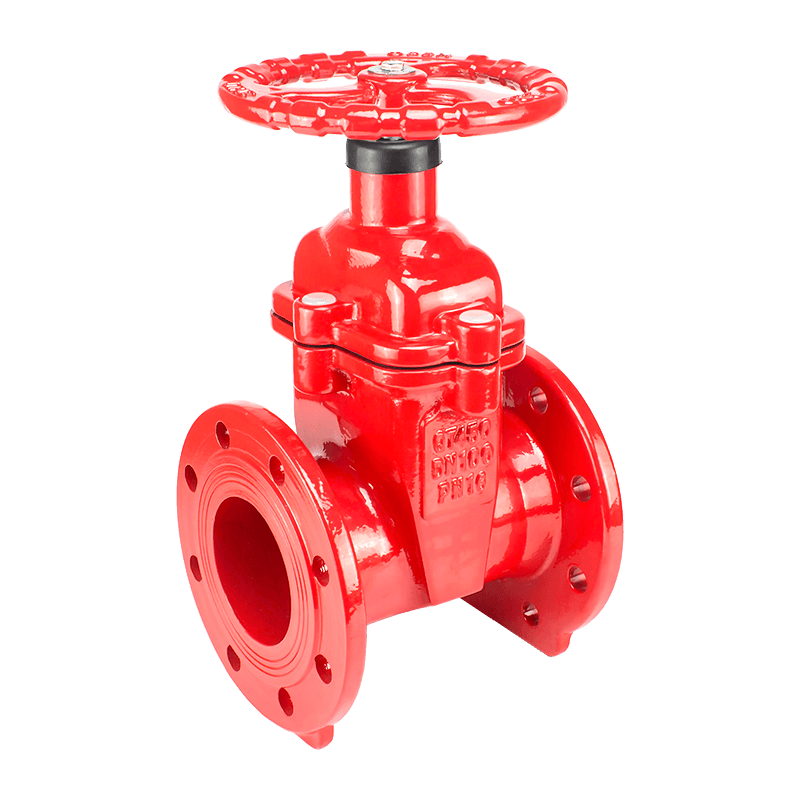

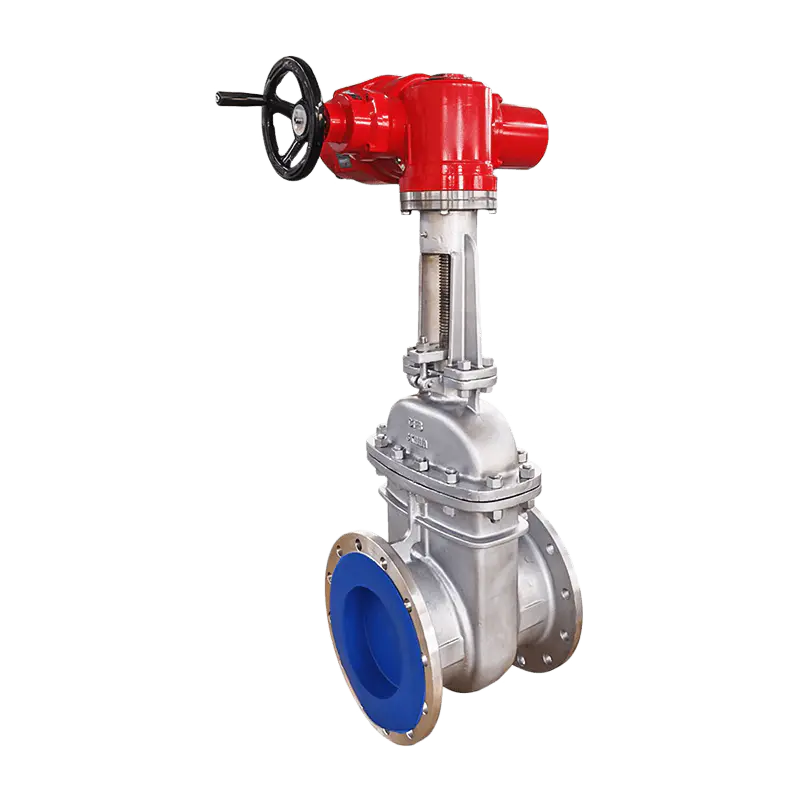

Stainless Steel/Cast Iron Gate Valves Suppliers

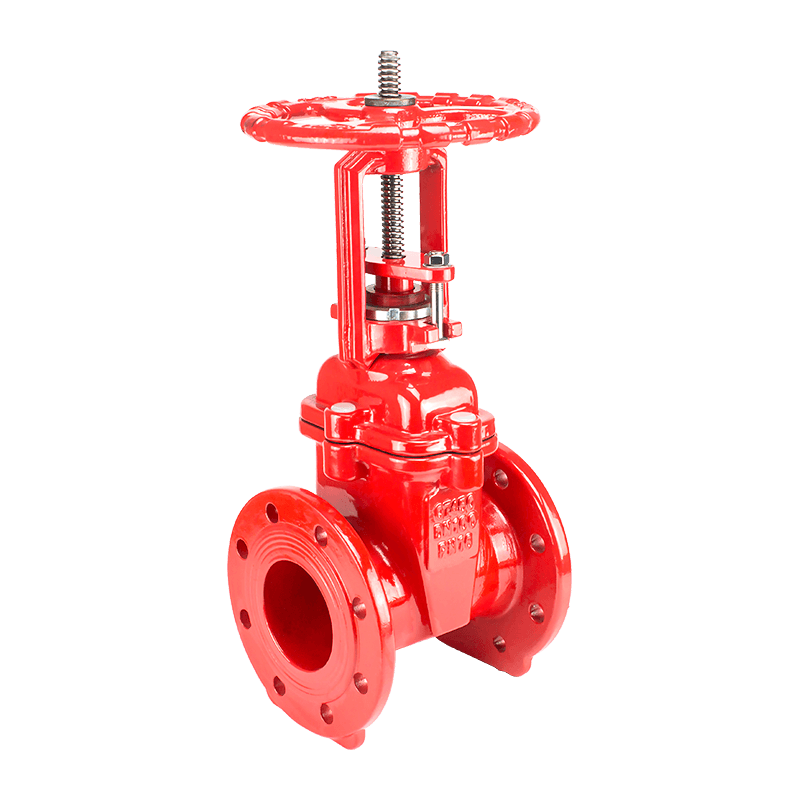

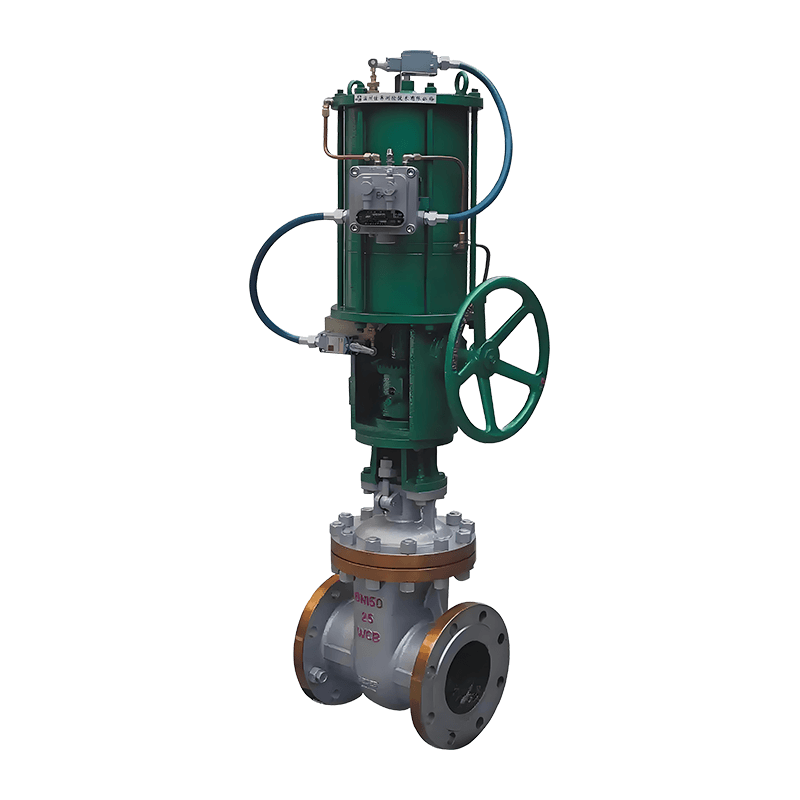

VATTEN's gate valve series includes pneumatic, electric, and manual options designed to meet the needs of various industries. These valves are specifically crafted to provide reliable performance in fluid control systems, making them ideal for water treatment plants, river channel operations, municipal water infrastructure, and industrial pipelines.

The pneumatic gate valves offer smooth, efficient control and are especially useful in automated systems where quick, responsive action is crucial. Meanwhile, the electric gate valves provide precise and consistent operation with the added advantage of integration into smart systems for remote control and monitoring.

For projects that require manual operation, VATTEN’s manual gate valves offer robust and easy-to-operate solutions, ensuring that users can maintain control even in demanding environments. No matter the application, VATTEN gate valves are built to deliver durability and high performance, ensuring the smooth operation of fluid systems across diverse sectors.

Vatten Valve Group, a globally renowned industrial automation valve enterprise originating from Saarland, Germany, specializes in the research, development, and manufacturing of core products such as automatic control ball valves, butterfly valves, and regulating valves. Leveraging our exceptional technological expertise, we deliver innovative valve solutions and professional technical support to critical industries including energy, chemical, water treatment, pharmaceutical, and food processing.

As Stainless Steel Gate Valves Suppliers and Cast Iron Gate Valves Factory, the Group operates four state-of-the-art manufacturing bases strategically located in Shanghai, Tianjin, Lishui, and Jiaxing, China. To better serve international markets, we have established branch offices in key strategic locations including the United Kingdom, Turkey, Belarus, Saudi Arabia, and Indonesia. The establishment of our Indonesian office significantly enhances our service capabilities in the Southeast Asian market, ensuring timely and efficient technical support and services for local partners and clients.

Rooted in the German tradition of precision manufacturing, Vatten Valve maintains its focus on automatic control valves while strictly adhering to international quality standards. Provide Custom Stainless Steel Gate Valves. We are committed to continuous innovation, providing customers with superior performance products, professional technical support, and comprehensive fluid control solutions, empowering them to address complex industrial fluid control challenges.

-

-

Bottom discharge valves are flow-control devices installed at the lowest point of a vessel, tank, or hopper to allow co...

READ MORE -

Electric Flow Control Valves: Key Answer and Practical Value Electric flow control valves regulate fluid flow automatic...

READ MORE -

Key Conclusion: Why Check Valves Are Essential in Fluid Systems Check valves are installed to allow fluid to flow in on...

READ MORE -

Such a scene often occurs during control valve selection meetings: The procurement manager asked: "Why not use this bal...

READ MORE

How Do Stainless Steel Gate Valves Compare to Other Types of Valves?

Gate valves are essential components in fluid control systems, used to start or stop the flow of liquids or gases in pipelines. Among the various types of gate valves, stainless steel gate valves stand out due to their durability, corrosion resistance, and ability to withstand high-pressure environments. In contrast, cast iron gate valves and other materials like brass or bronze offer their own unique set of advantages depending on the application. This article explores how stainless steel gate valves compare to other types of gate valves, highlighting key differences in materials, performance, applications, and maintenance.

What Are Gate Valves?

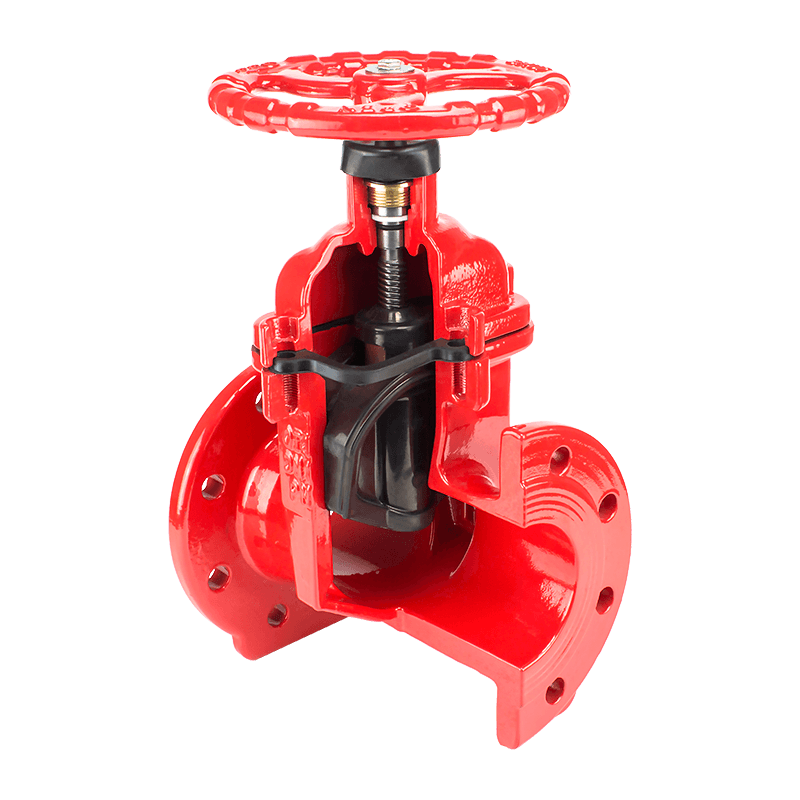

Gate valves are used to regulate the flow of fluids through pipes by raising or lowering a wedge-shaped gate. They are designed for fully opening or fully closing the flow of liquid or gas, making them ideal for on/off control. Unlike other valves, gate valves are not suitable for throttling or flow regulation, as partial opening can lead to erosion of the sealing surfaces.

Gate valves are available in various materials, including stainless steel, cast iron, bronze, and PVC, each offering different performance characteristics. The material choice of the valve directly impacts its strength, resistance to corrosion, durability, and the environments in which it can be used.

Stainless Steel Gate Valves vs Cast Iron Gate Valves

Stainless steel and cast iron are two of the most commonly used materials for gate valves. Each has its own set of advantages and limitations depending on the specific needs of the application. Below is a detailed comparison of stainless steel gate valves and cast iron gate valves:

1. Durability and Strength

One of the primary factors to consider when selecting a gate valve is its durability and strength. Stainless steel is known for its high tensile strength, resistance to corrosion, and ability to withstand extreme temperatures and pressures. These properties make stainless steel gate valves ideal for harsh industrial environments, such as chemical processing plants, oil refineries, and power generation systems.

- Stainless Steel: Highly resistant to corrosion, stainless steel gate valves perform well in environments that expose the valve to corrosive substances, high temperatures, and pressure.

- Cast Iron: While cast iron gate valves are strong, they are more susceptible to corrosion and may not be as durable in extreme conditions. They are commonly used in lower-pressure systems and waterworks where high strength and corrosion resistance are less critical.

2. Corrosion Resistance

Corrosion resistance is another critical factor when selecting gate valves, especially in applications involving water, chemicals, or other corrosive fluids. Stainless steel, due to its alloy composition, offers superior resistance to rust, scale, and corrosion when exposed to moist or acidic environments.

- Stainless Steel: Excellent resistance to a wide range of corrosive substances, including chlorides, acids, and alkaline solutions, making it a preferred choice in marine environments, wastewater treatment, and chemical plants.

- Cast Iron: More susceptible to corrosion and rust, especially when exposed to moisture or chemicals. Although cast iron is cost-effective and durable in non-corrosive environments, it may require coatings or regular maintenance in environments where corrosion is a concern.

3. Cost

When comparing gate valves, cost is often a significant consideration, especially for large-scale projects. Cast iron is a less expensive material compared to stainless steel, making cast iron gate valves a more budget-friendly option for applications that do not require high strength or corrosion resistance.

- Stainless Steel: More expensive due to its superior strength, corrosion resistance, and durability. Stainless steel gate valves are best for applications where performance and long-term reliability outweigh initial cost considerations.

- Cast Iron: Less expensive and ideal for applications where budget is a primary concern, such as municipal water systems or non-critical industrial systems.

4. Weight

Weight can be an important consideration when installing and handling gate valves, especially in larger systems. Stainless steel gate valves are typically lighter than their cast iron counterparts, which can make installation easier and reduce the strain on supporting structures.

- Stainless Steel: Lighter than cast iron, making it easier to handle, install, and transport. This is an advantage in applications where space is limited, or frequent maintenance is required.

- Cast Iron: Heavier, which can add additional labor and handling costs during installation and maintenance.

5. Temperature and Pressure Tolerance

The temperature and pressure conditions that a valve is exposed to can significantly impact its performance and longevity. Stainless steel gate valves offer much higher temperature and pressure resistance compared to cast iron, making them suitable for more demanding applications.

- Stainless Steel: Can withstand extreme temperatures and high pressures, making it ideal for use in high-temperature industrial processes, steam systems, and oil and gas pipelines.

- Cast Iron: Generally used for lower-pressure applications and cannot handle the same temperature and pressure extremes as stainless steel. It is typically used in municipal water systems, HVAC, and lower-pressure systems.

Other Types of Gate Valves

In addition to stainless steel and cast iron, there are other materials used to manufacture gate valves, each suited to specific applications. Some common types of gate valves include:

- Brass Gate Valves: These are commonly used for water distribution systems in residential and commercial settings due to their corrosion resistance and ease of use.

- Bronze Gate Valves: Similar to brass, bronze gate valves offer good corrosion resistance and are typically used in applications where seawater or other corrosive fluids are involved.

- Plastic Gate Valves: Made from materials like PVC or CPVC, plastic gate valves are ideal for non-metallic fluid systems, such as chemical processing, where corrosion resistance is essential and weight is a concern.

Applications of Stainless Steel Gate Valves

Stainless steel gate valves are widely used across many industries due to their superior performance characteristics. Some of the most common applications include:

- Chemical Processing: Stainless steel gate valves are used in systems handling aggressive chemicals due to their corrosion resistance.

- Oil and Gas: Used for high-pressure and high-temperature applications in pipelines, refineries, and offshore platforms.

- Water Treatment: These valves are used in water treatment plants where resistance to corrosion and robust performance are critical.

- Food and Beverage: Stainless steel gate valves are essential in food production systems, where hygiene and corrosion resistance are paramount.

Conclusion

In conclusion, the choice between stainless steel gate valves, cast iron gate valves, and other types of gate valves depends on the specific needs of the application. Stainless steel gate valves are ideal for high-pressure, high-temperature, and corrosive environments, offering superior durability and performance. Cast iron gate valves, on the other hand, are better suited for low-pressure applications where cost is a primary concern. Understanding the differences in material properties, cost, and application requirements will help ensure that the right gate valve is selected for your system.

English

English Deutsch

Deutsch Indonesia

Indonesia